Aramid fibers, such as Kevlar, offer exceptional impact resistance and flexibility, making them ideal for pet accessories that require durability and comfort. Carbon fibers provide high stiffness and lightweight properties but lack the flexibility of aramid fibers, which can lead to brittleness under dynamic stress. Choosing aramid fibers for pet products ensures enhanced safety and long-lasting performance without compromising on comfort.

Table of Comparison

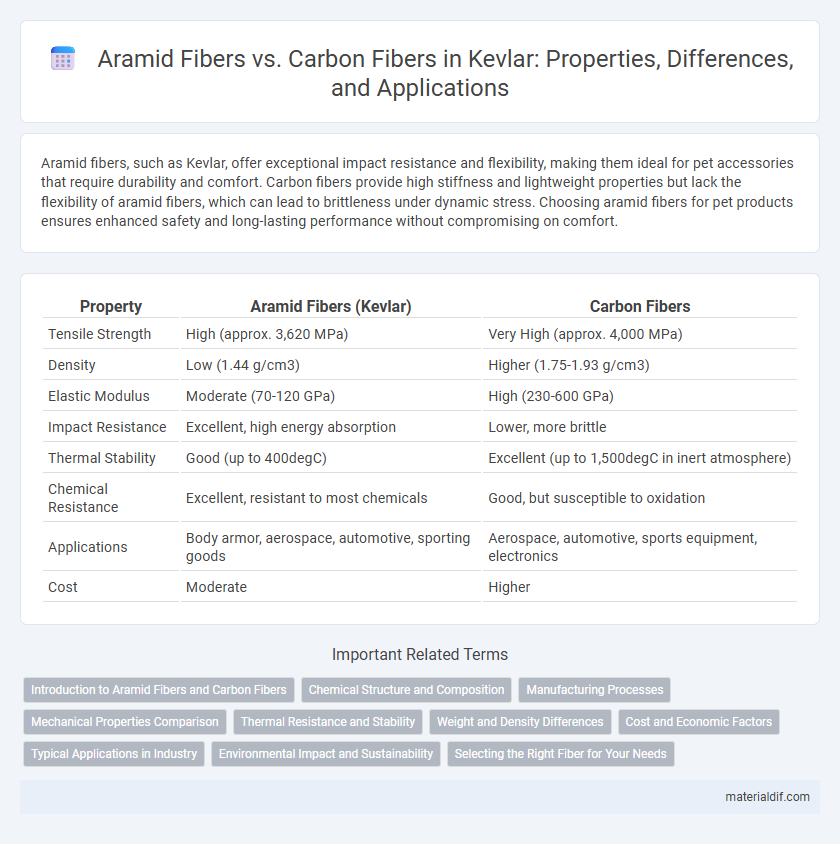

| Property | Aramid Fibers (Kevlar) | Carbon Fibers |

|---|---|---|

| Tensile Strength | High (approx. 3,620 MPa) | Very High (approx. 4,000 MPa) |

| Density | Low (1.44 g/cm3) | Higher (1.75-1.93 g/cm3) |

| Elastic Modulus | Moderate (70-120 GPa) | High (230-600 GPa) |

| Impact Resistance | Excellent, high energy absorption | Lower, more brittle |

| Thermal Stability | Good (up to 400degC) | Excellent (up to 1,500degC in inert atmosphere) |

| Chemical Resistance | Excellent, resistant to most chemicals | Good, but susceptible to oxidation |

| Applications | Body armor, aerospace, automotive, sporting goods | Aerospace, automotive, sports equipment, electronics |

| Cost | Moderate | Higher |

Introduction to Aramid Fibers and Carbon Fibers

Aramid fibers, such as Kevlar, are synthetic fibers known for exceptional strength, thermal stability, and resistance to impact and abrasion, making them ideal for ballistic and protective applications. Carbon fibers, composed primarily of carbon atoms bonded in a crystal alignment, offer superior stiffness, high tensile strength, and lightweight properties, extensively used in aerospace, automotive, and sports equipment industries. Both fiber types serve critical roles in advanced composite materials, with aramid fibers excelling in toughness and energy absorption, while carbon fibers provide unmatched rigidity and structural reinforcement.

Chemical Structure and Composition

Aramid fibers consist of long chains of polyamide molecules with aromatic rings linked by amide bonds, providing high tensile strength and thermal stability. Carbon fibers are composed mainly of carbon atoms arranged in graphite-like crystalline structures, resulting in exceptional stiffness and high strength-to-weight ratios. The differing chemical structures give aramid fibers better impact resistance and flexibility, while carbon fibers excel in rigidity and compressive strength.

Manufacturing Processes

Aramid fibers, such as Kevlar, are manufactured using a wet-spinning process where aromatic polyamides are dissolved in sulfuric acid and extruded into fibers, enabling high tensile strength and flexibility. Carbon fibers undergo a more complex manufacturing process involving the pyrolysis of polyacrylonitrile (PAN) or pitch precursors, which are stabilized, carbonized at high temperatures, and sometimes graphitized to achieve exceptional stiffness and thermal resistance. The manufacturing differences result in aramid fibers excelling in impact resistance and toughness, while carbon fibers prioritize modulus and strength for high-performance composite applications.

Mechanical Properties Comparison

Aramid fibers exhibit superior tensile strength and exceptional impact resistance compared to carbon fibers, making them ideal for ballistic protection and flexible armor applications. While carbon fibers offer higher stiffness and compressive strength, aramid fibers demonstrate better elongation at break and energy absorption, which contributes to enhanced durability under dynamic loads. The mechanical synergy between high toughness in aramid and rigidity in carbon fibers determines their selection based on specific performance requirements in aerospace, automotive, and protective gear industries.

Thermal Resistance and Stability

Aramid fibers, such as Kevlar, exhibit superior thermal resistance with decomposition temperatures around 450degC, maintaining structural integrity under high heat, whereas carbon fibers can withstand even higher temperatures exceeding 3000degC without significant deformation. The thermal stability of aramid fibers is crucial in applications requiring flame retardancy and resistance to thermal degradation, while carbon fibers excel in environments demanding extreme heat endurance and minimal thermal expansion. This distinction makes Kevlar ideal for protective gear and aerospace components where consistent performance under moderate heat is essential, contrasting with carbon fibers' roles in high-temperature structural reinforcements.

Weight and Density Differences

Aramid fibers like Kevlar have a lower density, approximately 1.44 g/cm3, compared to carbon fibers, which range from 1.75 to 1.95 g/cm3, making aramid fibers significantly lighter. This lower density contributes to Kevlar's superior strength-to-weight ratio, ideal for applications requiring lightweight yet strong materials. In contrast, carbon fibers offer higher stiffness and tensile strength but at a heavier weight, influencing their use in performance-critical industries where rigidity is prioritized over weight savings.

Cost and Economic Factors

Aramid fibers like Kevlar generally have a lower production cost compared to carbon fibers, making them more economically viable for applications requiring high tensile strength at a lower price point. The manufacturing process for aramid fibers involves less energy and fewer raw materials with high expenses, contributing to its cost-effectiveness in industries such as automotive and protective gear. Carbon fibers, while offering superior stiffness and lightweight properties, often incur higher costs due to expensive precursor materials and complex processing techniques, limiting their use to high-performance aerospace and sporting goods sectors where budget constraints are less critical.

Typical Applications in Industry

Aramid fibers excel in protective gear such as body armor, helmets, and cut-resistant gloves due to their high impact resistance and flexibility. Carbon fibers dominate aerospace, automotive, and sporting goods industries where lightweight strength and stiffness are critical for structural components and performance optimization. Both fibers are integral in composites, but aramid's toughness suits safety applications, while carbon fibers are preferred for rigidity and weight reduction.

Environmental Impact and Sustainability

Aramid fibers, such as Kevlar, exhibit lower carbon footprints and better recyclability compared to carbon fibers, making them more environmentally sustainable. The production of aramid fibers typically requires less energy and generates fewer greenhouse gas emissions, contributing to lower overall environmental impact. Carbon fibers, while offering superior strength-to-weight ratios, pose challenges in recycling and disposal, often leading to higher ecological burdens.

Selecting the Right Fiber for Your Needs

Aramid fibers like Kevlar offer exceptional impact resistance and high tensile strength, making them ideal for ballistic protection and lightweight composite structures. Carbon fibers excel in stiffness, thermal stability, and electrical conductivity, suited for aerospace and high-performance automotive applications. Choosing between aramid and carbon fibers depends on prioritizing flexibility and energy absorption versus rigidity and thermal endurance in your specific project.

Aramid fibers vs Carbon fibers Infographic

materialdif.com

materialdif.com