Kevlar pet products offer exceptional puncture resistance, making them ideal for pets prone to biting or scratching through materials. While abrasion resistance helps protect against wear from constant friction, Kevlar's puncture resistance is notably superior due to its tightly woven fibers that prevent sharp objects from penetrating. Choosing Kevlar for pet gear ensures enhanced durability, providing longer-lasting protection against both punctures and abrasion.

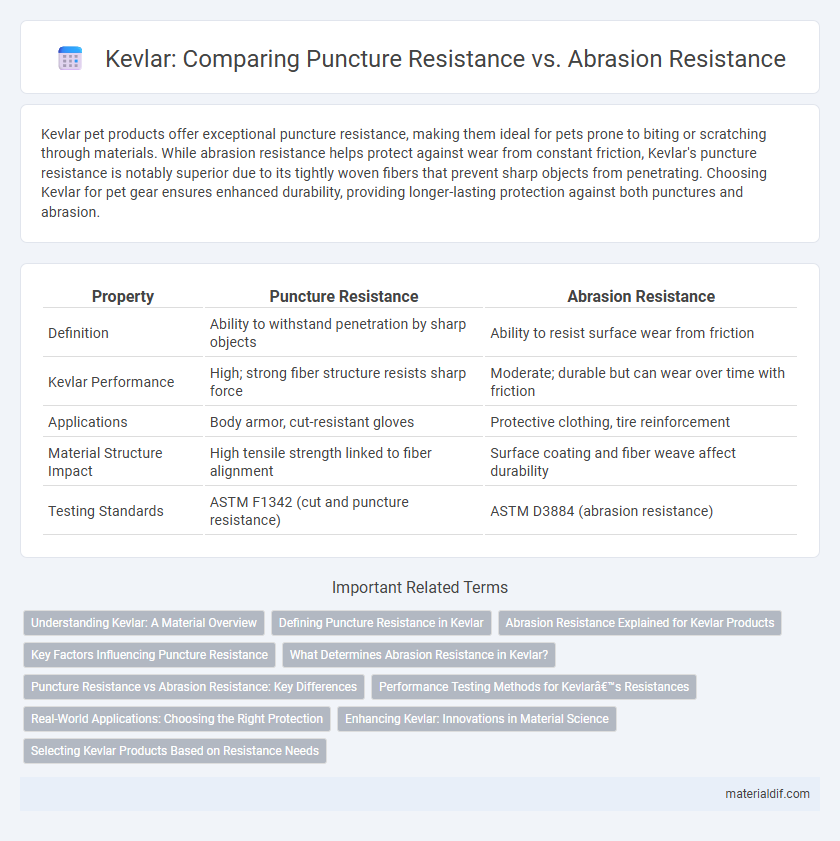

Table of Comparison

| Property | Puncture Resistance | Abrasion Resistance |

|---|---|---|

| Definition | Ability to withstand penetration by sharp objects | Ability to resist surface wear from friction |

| Kevlar Performance | High; strong fiber structure resists sharp force | Moderate; durable but can wear over time with friction |

| Applications | Body armor, cut-resistant gloves | Protective clothing, tire reinforcement |

| Material Structure Impact | High tensile strength linked to fiber alignment | Surface coating and fiber weave affect durability |

| Testing Standards | ASTM F1342 (cut and puncture resistance) | ASTM D3884 (abrasion resistance) |

Understanding Kevlar: A Material Overview

Kevlar exhibits exceptional puncture resistance due to its high tensile strength and molecular structure that absorbs and disperses force, making it ideal for protective gear and body armor. Its abrasion resistance, while significant, is comparatively lower, as the material can experience surface wear from friction over time. Understanding these properties helps optimize Kevlar applications in environments requiring durable, cut-resistant fabrics and enhanced impact protection.

Defining Puncture Resistance in Kevlar

Puncture resistance in Kevlar refers to the material's ability to prevent sharp objects from piercing through its fibers, making it ideal for protective gear like gloves and body armor. Kevlar's unique molecular structure, featuring tightly woven aramid fibers, allows it to absorb and disperse the energy from a puncture attempt, significantly reducing penetration risk. This property differs from abrasion resistance, which measures durability against surface wear rather than sharp impacts.

Abrasion Resistance Explained for Kevlar Products

Kevlar products exhibit exceptional abrasion resistance due to their tightly woven aramid fibers, which significantly reduce surface wear and extend material lifespan in demanding applications. The material's high tensile strength and molecular structure allow it to withstand repeated friction without degradation, making it ideal for protective gear and industrial uses. Abrasion resistance in Kevlar is crucial for maintaining the integrity of composites and fabrics subjected to constant mechanical stress.

Key Factors Influencing Puncture Resistance

Kevlar's puncture resistance primarily depends on fiber tensile strength, weave density, and resin matrix bonding, which together determine its ability to absorb and distribute localized impact forces. The alignment and layering of Kevlar fibers also play a crucial role in resisting penetration by sharp objects, while surface treatments can enhance fiber cohesion and durability. In contrast, abrasion resistance relies more on surface hardness and the ability to withstand repetitive friction, making it a distinct performance characteristic from puncture resistance.

What Determines Abrasion Resistance in Kevlar?

Abrasion resistance in Kevlar is primarily determined by its tightly woven aramid fibers, which create a robust surface that withstands friction and wear. The fiber density, yarn construction, and protective coatings also enhance Kevlar's ability to resist surface degradation from repeated contact. These factors collectively ensure Kevlar maintains its integrity and prolongs durability under abrasive conditions.

Puncture Resistance vs Abrasion Resistance: Key Differences

Puncture resistance measures Kevlar's ability to withstand sharp objects penetrating its fibers, essential for stab-proof and protective gear applications. Abrasion resistance evaluates the material's durability against surface wear caused by friction, critical for long-lasting use in industrial and tactical environments. The key difference lies in puncture resistance targeting penetration threats, while abrasion resistance focuses on surface degradation over time.

Performance Testing Methods for Kevlar’s Resistances

Kevlar's puncture resistance is typically evaluated using standardized tests such as the ASTM F1342, which measures penetration force by sharp objects, ensuring material integrity under high-stress conditions. Abrasion resistance is assessed through methods like the Taber Abrasion Test (ASTM D4060), quantifying material wear after repeated friction cycles to simulate real-world durability. Combining these performance testing methods provides critical data for optimizing Kevlar in protective gear, balancing sharp object penetration resistance with long-term surface durability.

Real-World Applications: Choosing the Right Protection

Kevlar's puncture resistance excels in protective gloves and body armor where sharp objects pose a threat, while its abrasion resistance is crucial for motorcycle gear and industrial clothing exposed to rough surfaces. Selecting Kevlar products depends on the specific hazard: puncture resistance for needle sticks and blade cuts, abrasion resistance for scraped or worn environments. Real-world applications demand materials tailored to either puncture or abrasion challenges, ensuring optimal safety and durability.

Enhancing Kevlar: Innovations in Material Science

Kevlar's puncture resistance is enhanced through the integration of high-tensile fibers that distribute force across a wider area, reducing the likelihood of material penetration. Innovations in nanotechnology and coating techniques improve abrasion resistance by creating protective barriers that minimize fiber wear during frictional contact. Advances such as shear-thickening fluids and cross-linked polymer matrices further optimize Kevlar's durability, enabling applications in extreme environments and protective gear.

Selecting Kevlar Products Based on Resistance Needs

Kevlar offers exceptional puncture resistance, making it ideal for applications requiring protection against sharp objects, while its abrasion resistance ensures durability in environments with continuous surface friction. Selecting Kevlar products depends on the specific resistance priority: puncture-resistant Kevlar fiber composites excel in protective gear, whereas abrasion-resistant Kevlar fabrics are preferred for heavy-duty clothing and industrial uses. Understanding the differences in Kevlar's molecular structure and weave density helps optimize performance tailored to puncture or abrasion resistance requirements.

Puncture resistance vs Abrasion resistance Infographic

materialdif.com

materialdif.com