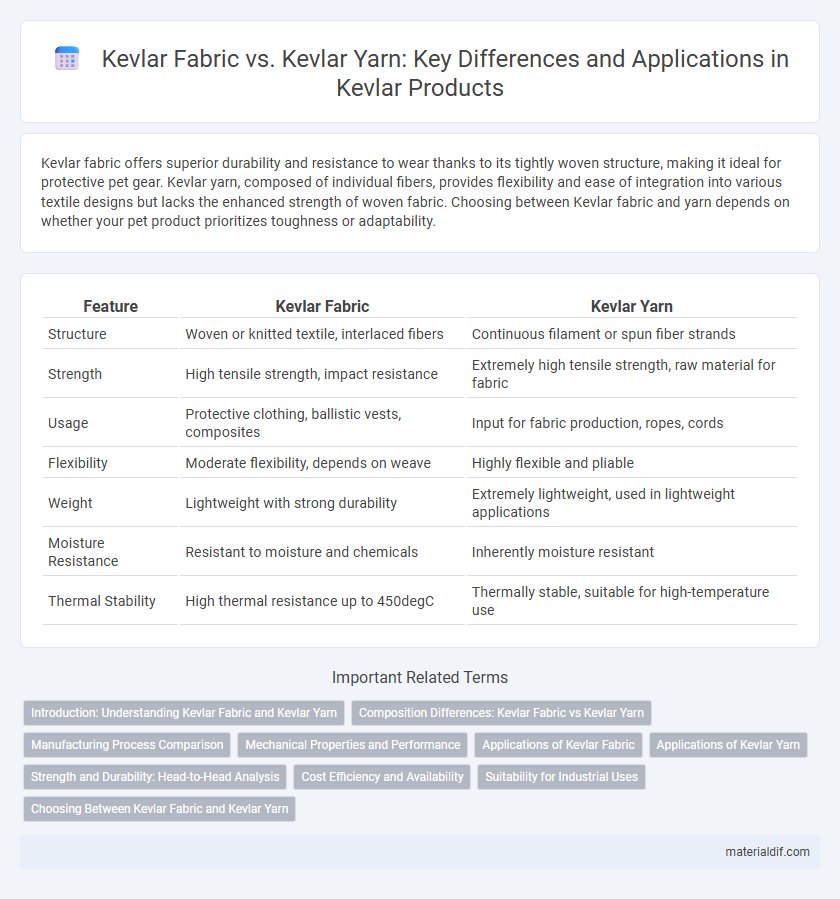

Kevlar fabric offers superior durability and resistance to wear thanks to its tightly woven structure, making it ideal for protective pet gear. Kevlar yarn, composed of individual fibers, provides flexibility and ease of integration into various textile designs but lacks the enhanced strength of woven fabric. Choosing between Kevlar fabric and yarn depends on whether your pet product prioritizes toughness or adaptability.

Table of Comparison

| Feature | Kevlar Fabric | Kevlar Yarn |

|---|---|---|

| Structure | Woven or knitted textile, interlaced fibers | Continuous filament or spun fiber strands |

| Strength | High tensile strength, impact resistance | Extremely high tensile strength, raw material for fabric |

| Usage | Protective clothing, ballistic vests, composites | Input for fabric production, ropes, cords |

| Flexibility | Moderate flexibility, depends on weave | Highly flexible and pliable |

| Weight | Lightweight with strong durability | Extremely lightweight, used in lightweight applications |

| Moisture Resistance | Resistant to moisture and chemicals | Inherently moisture resistant |

| Thermal Stability | High thermal resistance up to 450degC | Thermally stable, suitable for high-temperature use |

Introduction: Understanding Kevlar Fabric and Kevlar Yarn

Kevlar fabric consists of interwoven Kevlar yarns, creating a durable material widely used for protective clothing and industrial applications. Kevlar yarn, composed of continuous polymer fibers, serves as the fundamental building block offering high tensile strength and flexibility. Understanding the distinction between Kevlar fabric and yarn is essential for optimizing their use in ballistic protection, composites, and aerospace engineering.

Composition Differences: Kevlar Fabric vs Kevlar Yarn

Kevlar fabric is composed of tightly woven or knitted Kevlar yarns, creating a strong, flexible material used in protective clothing and equipment. Kevlar yarn consists of continuous filaments spun from Kevlar fibers, offering high tensile strength and durability as a raw material for producing various Kevlar products. The primary composition difference lies in the structural arrangement, where fabric integrates multiple yarns into a cohesive textile, whereas yarn represents an intermediate fiber form before fabric construction.

Manufacturing Process Comparison

Kevlar fabric is produced by weaving Kevlar yarns into a tightly knit material, which enhances its tensile strength and durability for use in body armor, tires, and composite materials. Kevlar yarns are created through a spinning process that transforms liquid crystal polymer solutions into strong, continuous fibers used as raw material for fabric production or reinforcement applications. The key manufacturing difference lies in yarn formation via spinning versus fabric construction through weaving or knitting, impacting the final material's flexibility and protective properties.

Mechanical Properties and Performance

Kevlar fabric exhibits superior tensile strength and higher impact resistance compared to Kevlar yarn due to its woven structure, which distributes load efficiently across fibers. Kevlar yarn, while offering excellent strength and flexibility, is primarily used as the foundational component in fabric production, impacting its elongation and modulus characteristics. Mechanical performance metrics such as Young's modulus and tear resistance are significantly enhanced in Kevlar fabric, making it ideal for applications requiring robust durability and abrasion resistance.

Applications of Kevlar Fabric

Kevlar fabric is widely used in protective clothing, such as bulletproof vests and helmets, due to its high tensile strength and lightweight properties. Its woven structure provides enhanced abrasion resistance and flexibility compared to Kevlar yarn, making it ideal for applications requiring durability and impact resistance. Kevlar fabric also finds extensive use in aerospace, automotive, and sporting goods industries, where strong, lightweight materials improve safety and performance.

Applications of Kevlar Yarn

Kevlar yarn is primarily utilized in applications requiring high tensile strength combined with flexibility, such as in the manufacturing of ropes, cables, and ballistic fabrics. Its continuous filament structure enhances durability and resistance to abrasion, making it ideal for protective clothing, composites in aerospace, and military gear. Industries favor Kevlar yarn for reinforcing materials where lightweight and high-performance fiber reinforcement is critical.

Strength and Durability: Head-to-Head Analysis

Kevlar fabric exhibits superior strength and durability compared to Kevlar yarn due to its woven structure that evenly distributes stress across fibers, enhancing resistance to abrasion and impact. Kevlar yarn, while inherently strong on a fiber level, is more vulnerable to individual strand damage and less effective at load distribution without fabric reinforcement. The composite nature of Kevlar fabric ensures enhanced performance in protective applications, making it preferable for ballistic and industrial uses.

Cost Efficiency and Availability

Kevlar fabric offers greater cost efficiency due to bulk production and ready availability, making it ideal for large-scale applications requiring consistent quality. Kevlar yarn, while more expensive per unit length, provides flexibility for custom manufacturing and specialized uses but is less readily available in bulk quantities. Choosing between Kevlar fabric and yarn depends on balancing budget constraints with specific production needs.

Suitability for Industrial Uses

Kevlar fabric offers enhanced durability and abrasion resistance, making it highly suitable for protective clothing and industrial applications requiring robust impact protection. Kevlar yarn provides flexibility and can be woven into various textile forms, ideal for customized industrial uses such as ropes, cables, and composite reinforcements. The choice between Kevlar fabric and yarn depends on the specific industrial requirements for strength, flexibility, and environmental resistance.

Choosing Between Kevlar Fabric and Kevlar Yarn

Kevlar fabric offers a durable, woven structure ideal for protective clothing and ballistic applications, providing enhanced abrasion resistance and flexibility. Kevlar yarn, composed of continuous filaments, is better suited for high-tensile strength uses such as composite reinforcement and industrial rope manufacturing. Choosing between Kevlar fabric and yarn depends on the specific performance requirements, with fabric optimized for impact resistance and yarn tailored for tensile strength and versatility in reinforcement.

Kevlar Fabric vs Kevlar Yarn Infographic

materialdif.com

materialdif.com