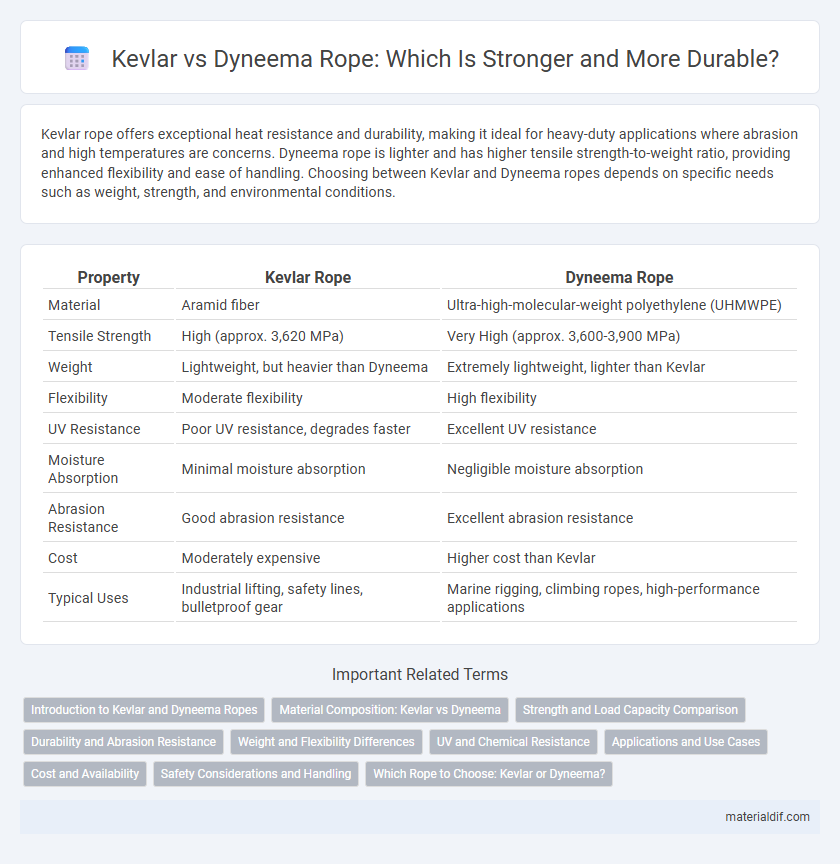

Kevlar rope offers exceptional heat resistance and durability, making it ideal for heavy-duty applications where abrasion and high temperatures are concerns. Dyneema rope is lighter and has higher tensile strength-to-weight ratio, providing enhanced flexibility and ease of handling. Choosing between Kevlar and Dyneema ropes depends on specific needs such as weight, strength, and environmental conditions.

Table of Comparison

| Property | Kevlar Rope | Dyneema Rope |

|---|---|---|

| Material | Aramid fiber | Ultra-high-molecular-weight polyethylene (UHMWPE) |

| Tensile Strength | High (approx. 3,620 MPa) | Very High (approx. 3,600-3,900 MPa) |

| Weight | Lightweight, but heavier than Dyneema | Extremely lightweight, lighter than Kevlar |

| Flexibility | Moderate flexibility | High flexibility |

| UV Resistance | Poor UV resistance, degrades faster | Excellent UV resistance |

| Moisture Absorption | Minimal moisture absorption | Negligible moisture absorption |

| Abrasion Resistance | Good abrasion resistance | Excellent abrasion resistance |

| Cost | Moderately expensive | Higher cost than Kevlar |

| Typical Uses | Industrial lifting, safety lines, bulletproof gear | Marine rigging, climbing ropes, high-performance applications |

Introduction to Kevlar and Dyneema Ropes

Kevlar rope is known for its exceptional tensile strength, heat resistance, and durability, making it ideal for applications requiring high-performance materials. Dyneema rope offers superior strength-to-weight ratio and excellent cut resistance, providing flexibility and lightweight advantages in marine and rescue operations. Both Kevlar and Dyneema ropes deliver unique benefits depending on specific industrial or commercial uses, with Kevlar excelling in thermal stability and Dyneema prioritizing lightweight strength.

Material Composition: Kevlar vs Dyneema

Kevlar rope is made from aramid fibers known for high tensile strength, heat resistance, and excellent durability, making it ideal for heavy-duty applications. Dyneema rope is composed of ultra-high-molecular-weight polyethylene (UHMWPE), offering superior strength-to-weight ratio, low stretch, and exceptional resistance to moisture and UV radiation. The choice between Kevlar and Dyneema ropes depends on the specific requirements of strength, flexibility, and environmental resistance.

Strength and Load Capacity Comparison

Kevlar rope exhibits superior tensile strength and heat resistance, making it ideal for high-stress environments where durability and thermal stability are critical. Dyneema rope offers a higher strength-to-weight ratio, boasting exceptional load capacity while being significantly lighter and more flexible than Kevlar. When comparing strength and load capacity, Dyneema typically outperforms Kevlar in weight efficiency, but Kevlar stands out in resistance to abrasion and extreme temperatures.

Durability and Abrasion Resistance

Kevlar rope offers superior durability due to its high tensile strength and resistance to heat, making it ideal for heavy-duty applications where exposure to extreme conditions is common. Dyneema rope excels in abrasion resistance, providing excellent performance in environments with frequent friction and contact with rough surfaces. While Kevlar retains strength under high temperatures better than Dyneema, the latter outperforms Kevlar in flexibility and resistance to UV degradation, influencing overall rope lifespan depending on use cases.

Weight and Flexibility Differences

Kevlar rope is considerably heavier than Dyneema rope due to its higher density, which impacts portability and ease of handling in various applications. Dyneema fibers offer superior flexibility, allowing the rope to bend and coil more easily without compromising strength or durability. Weight savings and enhanced flexibility make Dyneema a preferred choice for activities requiring lightweight gear and compact storage.

UV and Chemical Resistance

Kevlar rope exhibits superior chemical resistance, maintaining strength and durability when exposed to harsh solvents and acids, unlike Dyneema, which can degrade under certain chemical conditions. However, Dyneema outperforms Kevlar in UV resistance, with greater resilience to sun exposure preventing significant weakening or color fading over time. Selecting between Kevlar and Dyneema ropes depends on the environmental factors where chemical exposure or prolonged UV exposure predominates.

Applications and Use Cases

Kevlar rope excels in high-temperature environments and applications requiring exceptional cut and abrasion resistance, making it ideal for military, industrial lifting, and firefighting uses. Dyneema rope offers superior strength-to-weight ratio and exceptional UV resistance, preferred in marine, climbing, and rescue operations where lightweight performance and durability are critical. Both materials serve distinct roles based on environmental conditions and specific load requirements, optimizing safety and functionality in their respective fields.

Cost and Availability

Kevlar rope is generally more affordable than Dyneema rope, making it a cost-effective choice for many industrial and recreational applications. Kevlar fibers are widely produced and readily available in various rope forms, contributing to its accessibility in the market. Dyneema rope, known for its superior strength and lighter weight, tends to be more expensive and may have limited availability depending on supplier inventory and specialized demand.

Safety Considerations and Handling

Kevlar rope offers exceptional heat resistance and durability, making it suitable for high-temperature environments, while Dyneema rope excels in strength-to-weight ratio and is less prone to stretch, enhancing safety in dynamic loads. Kevlar's stiffness requires careful handling to avoid abrasion and maintain structural integrity, whereas Dyneema's flexibility improves ease of use and reduces hand fatigue. Safety considerations emphasize Kevlar's superior cut resistance and flame retardancy compared to Dyneema, which is more UV sensitive and requires protection from prolonged sun exposure to maintain performance.

Which Rope to Choose: Kevlar or Dyneema?

Kevlar rope offers exceptional heat resistance and durability, making it ideal for high-temperature applications and situations requiring abrasion resistance. Dyneema rope excels in tensile strength and lightweight properties, providing superior load-bearing capacity with less bulk and stretch. Choosing between Kevlar and Dyneema ropes depends on whether heat resistance and durability or strength-to-weight ratio and flexibility are more critical for your specific needs.

Kevlar rope vs Dyneema rope Infographic

materialdif.com

materialdif.com