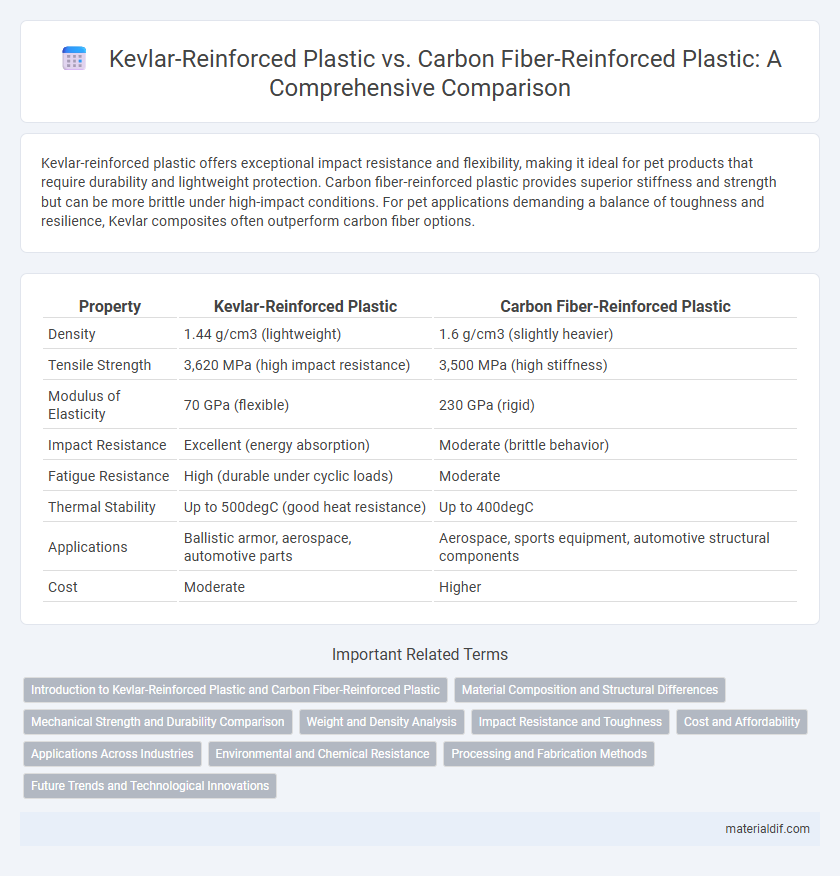

Kevlar-reinforced plastic offers exceptional impact resistance and flexibility, making it ideal for pet products that require durability and lightweight protection. Carbon fiber-reinforced plastic provides superior stiffness and strength but can be more brittle under high-impact conditions. For pet applications demanding a balance of toughness and resilience, Kevlar composites often outperform carbon fiber options.

Table of Comparison

| Property | Kevlar-Reinforced Plastic | Carbon Fiber-Reinforced Plastic |

|---|---|---|

| Density | 1.44 g/cm3 (lightweight) | 1.6 g/cm3 (slightly heavier) |

| Tensile Strength | 3,620 MPa (high impact resistance) | 3,500 MPa (high stiffness) |

| Modulus of Elasticity | 70 GPa (flexible) | 230 GPa (rigid) |

| Impact Resistance | Excellent (energy absorption) | Moderate (brittle behavior) |

| Fatigue Resistance | High (durable under cyclic loads) | Moderate |

| Thermal Stability | Up to 500degC (good heat resistance) | Up to 400degC |

| Applications | Ballistic armor, aerospace, automotive parts | Aerospace, sports equipment, automotive structural components |

| Cost | Moderate | Higher |

Introduction to Kevlar-Reinforced Plastic and Carbon Fiber-Reinforced Plastic

Kevlar-reinforced plastic combines aramid fiber known for high tensile strength and impact resistance with a polymer matrix, resulting in materials widely used in ballistic protection and automotive parts. Carbon fiber-reinforced plastic integrates carbon fibers valued for exceptional stiffness, lightweight properties, and thermal stability into a resin matrix, making it ideal for aerospace, sports equipment, and high-performance automotive components. Both composites offer superior strength-to-weight ratios, but Kevlar excels in impact resistance while carbon fiber provides enhanced rigidity.

Material Composition and Structural Differences

Kevlar-reinforced plastic consists of aromatic polyamide fibers embedded in a polymer matrix, providing exceptional toughness and impact resistance due to its high tensile strength and energy absorption capabilities. Carbon fiber-reinforced plastic uses carbon fibers that offer superior stiffness and high strength-to-weight ratio, resulting in a rigid and lightweight composite ideal for high-performance applications. The structural difference lies in Kevlar's fibrous, flexible nature which enhances durability and fracture resistance, whereas carbon fiber's crystalline structure delivers enhanced rigidity and dimensional stability under stress.

Mechanical Strength and Durability Comparison

Kevlar-reinforced plastic offers exceptional tensile strength and impact resistance, making it highly durable under dynamic loads and ideal for applications requiring high toughness. Carbon fiber-reinforced plastic provides superior stiffness and compressive strength, excelling in rigidity and fatigue resistance for structural components demanding lightweight and high-strength materials. In terms of mechanical strength and durability, Kevlar composites outperform in energy absorption and crack propagation resistance, whereas carbon fiber composites dominate in modulus, tensile load capacity, and long-term dimensional stability.

Weight and Density Analysis

Kevlar-reinforced plastic exhibits a lower density of approximately 1.44 g/cm3 compared to carbon fiber-reinforced plastic, which typically ranges around 1.6 g/cm3, making Kevlar composites lighter for similar volume applications. Kevlar's specific strength-to-weight ratio offers significant weight savings in aerospace and automotive industries where reducing mass is critical. The lower density of Kevlar composites enhances impact resistance without substantially increasing structural weight, whereas carbon fiber composites provide higher stiffness at slightly increased density.

Impact Resistance and Toughness

Kevlar-reinforced plastic exhibits superior impact resistance and toughness compared to carbon fiber-reinforced plastic due to Kevlar's high energy absorption and excellent crack resistance properties. While carbon fiber-reinforced plastic offers greater stiffness and strength, Kevlar composites excel in applications requiring enhanced durability against sudden impacts and dynamic loading. The molecular structure of Kevlar enables it to dissipate stress more effectively, resulting in improved toughness and reduced brittleness in composite materials.

Cost and Affordability

Kevlar-reinforced plastic generally offers a lower cost compared to carbon fiber-reinforced plastic, making it more affordable for applications requiring high impact resistance. While carbon fiber provides superior stiffness and strength-to-weight ratio, its production costs and raw material prices are significantly higher. Kevlar composites are favored in budget-conscious projects needing abrasion resistance and toughness without the premium price of carbon fiber.

Applications Across Industries

Kevlar-reinforced plastic excels in applications requiring high impact resistance and ballistic protection, prominently used in aerospace, military armor, and automotive safety components. Carbon fiber-reinforced plastic offers superior stiffness and strength-to-weight ratios, making it ideal for aerospace structures, high-performance sports equipment, and automotive parts focused on lightweight durability. Both materials drive innovation across industries like marine, industrial manufacturing, and consumer electronics by optimizing strength, weight, and cost efficiency for specialized applications.

Environmental and Chemical Resistance

Kevlar-reinforced plastic exhibits superior resistance to chemicals such as solvents, acids, and alkalis, making it ideal for harsh environmental conditions where corrosion resistance is critical. Carbon fiber-reinforced plastic offers excellent mechanical strength but tends to be more susceptible to chemical degradation and UV damage without protective coatings. Kevlar composites also provide better impact resistance and retain structural integrity in extreme temperatures, contributing to their durability in chemically aggressive and environmentally demanding applications.

Processing and Fabrication Methods

Kevlar-reinforced plastic typically requires specialized processing methods such as wet lay-up and resin transfer molding due to Kevlar's high toughness and sensitivity to cutting and heat. Carbon fiber-reinforced plastic often uses automated methods like filament winding and autoclave curing, benefiting from carbon fiber's rigidity and thermal stability. The choice between the two depends on the desired mechanical properties and production scale, with Kevlar demanding more careful handling during fabrication.

Future Trends and Technological Innovations

Kevlar-reinforced plastic is evolving with advancements in nano-enhancements and hybrid composites, improving impact resistance and thermal stability for aerospace and automotive applications. Carbon fiber-reinforced plastic innovations emphasize ultra-lightweight structures and increased fatigue resistance through enhanced resin matrices and 3D weaving techniques. Future trends are leaning towards multifunctional composites combining Kevlar and carbon fiber to synergize strength, flexibility, and durability in next-generation materials.

Kevlar-reinforced plastic vs Carbon fiber-reinforced plastic Infographic

materialdif.com

materialdif.com