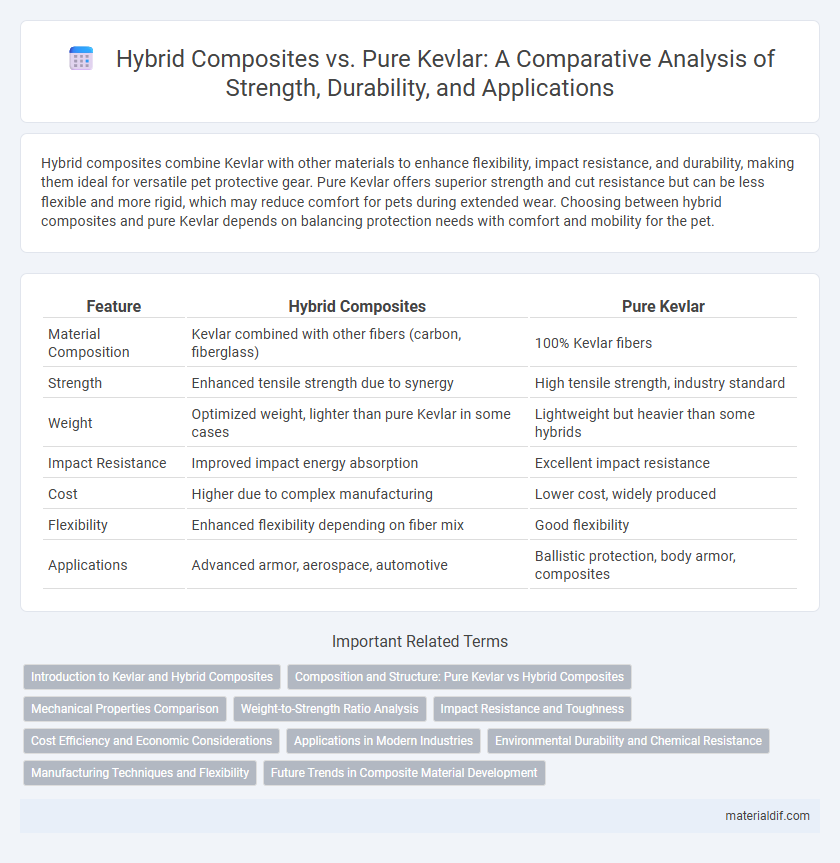

Hybrid composites combine Kevlar with other materials to enhance flexibility, impact resistance, and durability, making them ideal for versatile pet protective gear. Pure Kevlar offers superior strength and cut resistance but can be less flexible and more rigid, which may reduce comfort for pets during extended wear. Choosing between hybrid composites and pure Kevlar depends on balancing protection needs with comfort and mobility for the pet.

Table of Comparison

| Feature | Hybrid Composites | Pure Kevlar |

|---|---|---|

| Material Composition | Kevlar combined with other fibers (carbon, fiberglass) | 100% Kevlar fibers |

| Strength | Enhanced tensile strength due to synergy | High tensile strength, industry standard |

| Weight | Optimized weight, lighter than pure Kevlar in some cases | Lightweight but heavier than some hybrids |

| Impact Resistance | Improved impact energy absorption | Excellent impact resistance |

| Cost | Higher due to complex manufacturing | Lower cost, widely produced |

| Flexibility | Enhanced flexibility depending on fiber mix | Good flexibility |

| Applications | Advanced armor, aerospace, automotive | Ballistic protection, body armor, composites |

Introduction to Kevlar and Hybrid Composites

Kevlar, a high-strength aramid fiber known for its exceptional tensile strength and lightweight properties, serves as a core material in advanced protective gear and aerospace applications. Hybrid composites combine Kevlar with other fibers such as carbon or glass to enhance specific mechanical properties, including stiffness, impact resistance, and durability. These hybrid materials offer tailored performance advantages over pure Kevlar by optimizing strength-to-weight ratios and addressing limitations like UV sensitivity and compression weakness.

Composition and Structure: Pure Kevlar vs Hybrid Composites

Pure Kevlar consists solely of aramid fibers known for exceptional tensile strength and impact resistance, arranged in tightly woven or unidirectional structures to maximize performance. Hybrid composites combine Kevlar with other materials such as carbon fiber, fiberglass, or epoxy resins, creating a synergistic matrix that enhances stiffness, durability, and weight-to-strength ratios. The structural integration in hybrids allows tailored mechanical properties, optimizing impact resistance and flexibility beyond what pure Kevlar can achieve alone.

Mechanical Properties Comparison

Hybrid composites combining Kevlar with carbon or glass fibers demonstrate enhanced tensile strength and impact resistance compared to pure Kevlar composites, balancing stiffness and energy absorption. Pure Kevlar boasts superior toughness and flexibility, making it ideal for applications requiring high impact resistance and ballistic protection. Mechanical testing reveals that hybrid composites offer improved fatigue resistance and structural integrity, optimizing performance in demanding environments such as aerospace and automotive industries.

Weight-to-Strength Ratio Analysis

Hybrid composites combining Kevlar with carbon fiber or fiberglass exhibit an enhanced weight-to-strength ratio compared to pure Kevlar, optimizing both tensile strength and stiffness while reducing overall weight. Pure Kevlar offers outstanding impact resistance and energy absorption but tends to have a lower stiffness-to-weight ratio, making hybrids preferable for applications requiring structural rigidity and lightweight properties. Evaluations show hybrid composites achieve up to 20% weight savings without compromising strength, making them ideal for aerospace and automotive industries demanding high-performance materials.

Impact Resistance and Toughness

Hybrid composites combining Kevlar fibers with materials like carbon or glass enhance impact resistance by leveraging the complementary strengths of each fiber type. Pure Kevlar offers exceptional toughness and energy absorption due to its high tensile strength and flexibility but may lack stiffness that other fibers contribute. The balanced synergy in hybrid composites results in improved overall impact resistance and toughness, making them suitable for applications requiring both durability and lightweight protection.

Cost Efficiency and Economic Considerations

Hybrid composites combining Kevlar with other fibers often reduce material costs compared to pure Kevlar composites, making them more cost-efficient for large-scale applications. The integration of lower-cost fibers balances performance and budget, optimizing economic viability without significantly compromising strength and durability. Manufacturers benefit from hybrid composites by achieving improved production scalability and reduced overall expenditure on raw materials and processing.

Applications in Modern Industries

Hybrid composites combining Kevlar with carbon fiber or fiberglass enhance tensile strength and impact resistance, making them ideal for aerospace structures and automotive safety components. Pure Kevlar offers superior ballistic protection and lightweight durability, preferred in personal armor and high-performance sports equipment. Industries select hybrid composites for optimized mechanical performance, while pure Kevlar remains essential for maximum energy absorption and abrasion resistance.

Environmental Durability and Chemical Resistance

Hybrid composites combining Kevlar with materials like carbon fiber or fiberglass exhibit enhanced environmental durability compared to pure Kevlar, particularly in resisting moisture and UV exposure. Pure Kevlar excels in chemical resistance against solvents, oils, and fuels but may degrade faster under prolonged UV radiation and harsh environmental conditions. Hybrid composites balance the inherent chemical resistance of Kevlar with improved structural stability and longevity in diverse, challenging environments.

Manufacturing Techniques and Flexibility

Hybrid composites integrating Kevlar combine materials like carbon fiber or fiberglass through advanced manufacturing techniques such as resin transfer molding and filament winding, enhancing structural flexibility and tailoring mechanical properties. Pure Kevlar manufacturing typically involves processes like weaving and resin impregnation, resulting in lightweight yet less versatile fabrics with high tensile strength but limited adaptability in complex shapes. The hybrid approach allows for optimized flexibility and performance in diverse applications, balancing Kevlar's impact resistance with complementary materials' stiffness and durability.

Future Trends in Composite Material Development

Hybrid composites combining Kevlar with carbon fiber or fiberglass enhance mechanical properties and reduce weight compared to pure Kevlar, driving innovation in aerospace and automotive industries. Future trends emphasize nanotechnology integration and bio-based resins to improve environmental sustainability and performance durability. Advanced manufacturing techniques like automated fiber placement are expected to optimize hybrid composite production, enabling scalable, cost-effective applications.

Hybrid Composites vs Pure Kevlar Infographic

materialdif.com

materialdif.com