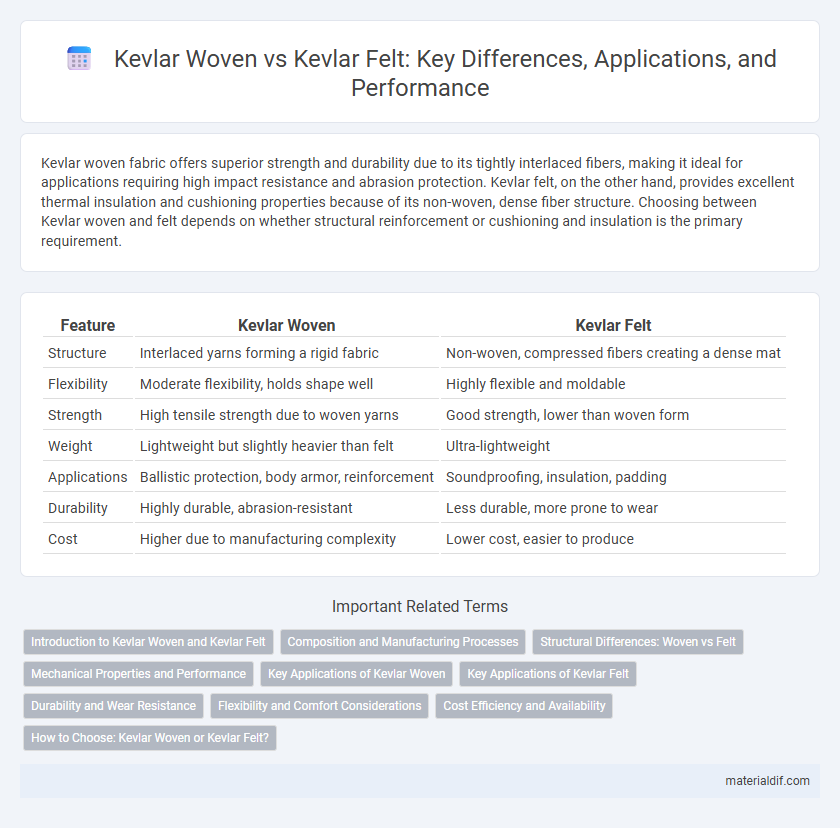

Kevlar woven fabric offers superior strength and durability due to its tightly interlaced fibers, making it ideal for applications requiring high impact resistance and abrasion protection. Kevlar felt, on the other hand, provides excellent thermal insulation and cushioning properties because of its non-woven, dense fiber structure. Choosing between Kevlar woven and felt depends on whether structural reinforcement or cushioning and insulation is the primary requirement.

Table of Comparison

| Feature | Kevlar Woven | Kevlar Felt |

|---|---|---|

| Structure | Interlaced yarns forming a rigid fabric | Non-woven, compressed fibers creating a dense mat |

| Flexibility | Moderate flexibility, holds shape well | Highly flexible and moldable |

| Strength | High tensile strength due to woven yarns | Good strength, lower than woven form |

| Weight | Lightweight but slightly heavier than felt | Ultra-lightweight |

| Applications | Ballistic protection, body armor, reinforcement | Soundproofing, insulation, padding |

| Durability | Highly durable, abrasion-resistant | Less durable, more prone to wear |

| Cost | Higher due to manufacturing complexity | Lower cost, easier to produce |

Introduction to Kevlar Woven and Kevlar Felt

Kevlar woven fabric consists of high-strength fibers interlaced in a precise pattern, providing exceptional tensile strength, durability, and flexibility ideal for ballistic and structural applications. Kevlar felt, made from non-woven fibers pressed or bonded together, offers increased thickness and cushioning, enhancing impact absorption and thermal insulation properties. Both materials leverage Kevlar's inherent heat resistance and lightweight characteristics but serve distinct industrial needs based on their structural differences.

Composition and Manufacturing Processes

Kevlar woven fabric consists of tightly interlaced Kevlar fibers arranged in a grid-like pattern, providing high tensile strength and excellent flexibility, ideal for ballistic and protective applications. Kevlar felt is produced by bonding short Kevlar fibers randomly oriented through mechanical, chemical, or thermal processes, resulting in a dense, non-woven mat with superior insulation and impact absorption properties. Manufacturing woven Kevlar involves traditional weaving techniques, while felt production relies on mat-forming processes such as needle punching or resin binding to achieve the desired thickness and durability.

Structural Differences: Woven vs Felt

Kevlar woven fabric consists of interlaced continuous fibers creating a tight, grid-like structure that offers high tensile strength and excellent durability, ideal for ballistic protection and reinforcement applications. Kevlar felt, made from shorter, random fibers bonded together, provides superior impact absorption and thermal insulation but with less tensile strength compared to woven Kevlar. These structural differences influence their performance, where woven Kevlar excels in strength and flexibility, while felt Kevlar is preferred for padding and shock absorption.

Mechanical Properties and Performance

Kevlar woven fabrics exhibit superior tensile strength and dimensional stability due to their interlaced fiber structure, enhancing impact resistance and durability in demanding applications. Kevlar felt, composed of randomly oriented fibers, offers greater flexibility and improved energy absorption but with lower tensile strength and abrasion resistance compared to woven Kevlar. The mechanical performance of Kevlar woven materials is optimized for high-stress environments, while Kevlar felt excels in shock absorption and cushioning where pliability is critical.

Key Applications of Kevlar Woven

Kevlar woven fabric is extensively used in ballistic armor, offering high tensile strength and superior resistance to impact and penetration, making it ideal for bulletproof vests and military helmets. Its tightly interlaced fiber structure provides enhanced durability and flexibility compared to Kevlar felt, which is often utilized for heat insulation and padding applications. Key industries relying on Kevlar woven include aerospace, automotive, and personal protective equipment due to its lightweight, high-performance protective qualities.

Key Applications of Kevlar Felt

Kevlar felt is widely used in applications requiring thermal insulation, soundproofing, and gaskets due to its excellent heat resistance and durability. Unlike Kevlar woven fabric, which is favored for ballistic protection and structural reinforcement, Kevlar felt excels in sealing and vibration dampening in automotive and aerospace industries. Its unique fibrous mat structure enables superior compressibility and moisture resistance, making it ideal for high-performance industrial uses.

Durability and Wear Resistance

Kevlar woven fabric offers superior durability and wear resistance due to its tightly interlaced fibers, providing enhanced tensile strength and resistance to abrasion in demanding applications. Kevlar felt, while still strong, exhibits a softer, more flexible structure that delivers moderate durability but is more prone to wear under heavy mechanical stress. The choice between Kevlar woven and felt depends on the specific application, with woven Kevlar preferred for high-impact and high-friction environments requiring maximum longevity.

Flexibility and Comfort Considerations

Kevlar woven fabric offers higher tensile strength and durability but tends to be less flexible and breathable compared to Kevlar felt, which provides superior comfort through enhanced softness and pliability. Kevlar felt's non-woven structure allows for better air permeability, reducing heat retention and improving wearer comfort in extended use. Choosing between Kevlar woven and felt depends on the specific application's balance between protection requirements and flexibility or comfort needs.

Cost Efficiency and Availability

Kevlar woven fabric offers higher durability and strength per unit area, making it cost-effective for applications requiring reinforcement, though it often comes at a higher initial price and more limited availability. Kevlar felt, while less robust, provides a more affordable and readily available option for insulation and padding purposes, easing budget constraints in large-scale projects. Choosing between the two depends on balancing performance requirements with cost efficiency and accessibility in supply chains.

How to Choose: Kevlar Woven or Kevlar Felt?

Kevlar woven fabric offers superior tensile strength and durability, making it ideal for applications requiring high resistance to abrasion and impact, such as body armor or industrial gloves. Kevlar felt provides enhanced flexibility and cushioning, suited for thermal insulation, soundproofing, and lightweight padding in automotive or aerospace components. Choose Kevlar woven for structural integrity demands and Kevlar felt when comfort, flexibility, and insulation properties are prioritized.

Kevlar woven vs Kevlar felt Infographic

materialdif.com

materialdif.com