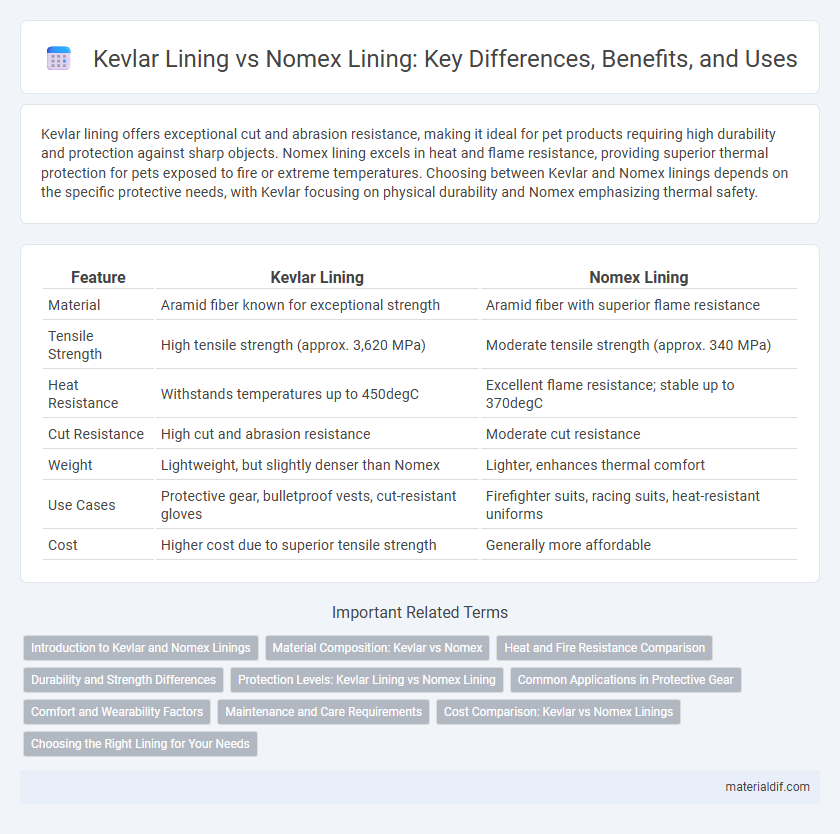

Kevlar lining offers exceptional cut and abrasion resistance, making it ideal for pet products requiring high durability and protection against sharp objects. Nomex lining excels in heat and flame resistance, providing superior thermal protection for pets exposed to fire or extreme temperatures. Choosing between Kevlar and Nomex linings depends on the specific protective needs, with Kevlar focusing on physical durability and Nomex emphasizing thermal safety.

Table of Comparison

| Feature | Kevlar Lining | Nomex Lining |

|---|---|---|

| Material | Aramid fiber known for exceptional strength | Aramid fiber with superior flame resistance |

| Tensile Strength | High tensile strength (approx. 3,620 MPa) | Moderate tensile strength (approx. 340 MPa) |

| Heat Resistance | Withstands temperatures up to 450degC | Excellent flame resistance; stable up to 370degC |

| Cut Resistance | High cut and abrasion resistance | Moderate cut resistance |

| Weight | Lightweight, but slightly denser than Nomex | Lighter, enhances thermal comfort |

| Use Cases | Protective gear, bulletproof vests, cut-resistant gloves | Firefighter suits, racing suits, heat-resistant uniforms |

| Cost | Higher cost due to superior tensile strength | Generally more affordable |

Introduction to Kevlar and Nomex Linings

Kevlar lining offers exceptional cut and abrasion resistance due to its aramid fiber composition, making it ideal for protective gear in high-risk industries. Nomex lining provides superior flame resistance and thermal stability, widely used in firefighting and military apparel. Both linings enhance safety, with Kevlar excelling in mechanical protection and Nomex in heat and fire protection.

Material Composition: Kevlar vs Nomex

Kevlar lining is made from para-aramid synthetic fibers known for exceptional tensile strength and resistance to impact, providing superior cut and abrasion protection. Nomex lining consists of meta-aramid fibers with inherent flame resistance and thermal stability, making it ideal for heat and fire protection. Comparing material composition, Kevlar excels in durability and mechanical strength, while Nomex offers enhanced flame retardancy and heat endurance.

Heat and Fire Resistance Comparison

Kevlar lining offers superior heat resistance with a decomposition temperature around 450degC, making it highly effective in protecting against extreme heat and flames. Nomex lining, while also flame-resistant, typically withstands temperatures up to 370degC, providing reliable protection but with slightly less thermal endurance than Kevlar. Both materials are essential in fire safety gear, but Kevlar's higher heat threshold makes it preferable in environments with intense and prolonged heat exposure.

Durability and Strength Differences

Kevlar lining offers superior durability and strength compared to Nomex lining due to its high tensile strength and resistance to abrasion, making it ideal for applications requiring enhanced impact protection. Kevlar fibers provide exceptional cut resistance and maintain structural integrity under extreme stress, whereas Nomex primarily excels in flame resistance but is less robust against physical wear. This makes Kevlar lining the preferred choice for environments demanding prolonged durability and mechanical toughness.

Protection Levels: Kevlar Lining vs Nomex Lining

Kevlar lining offers superior cut resistance and high tensile strength, making it ideal for protection against sharp objects and abrasion, whereas Nomex lining excels in flame resistance and thermal protection due to its inherent heat-retardant properties. Kevlar provides enhanced durability under mechanical stress, while Nomex is preferred in environments with intense heat or fire exposure. Both materials are vital in protective gear, but Kevlar is optimized for impact and cut hazards, and Nomex for fire and heat hazards.

Common Applications in Protective Gear

Kevlar lining is widely used in protective gear for its high tensile strength, impact resistance, and cut resistance, making it ideal for bulletproof vests, gloves, and helmets in law enforcement and military applications. Nomex lining is preferred in firefighting and industrial protective clothing due to its superior flame resistance and thermal stability, providing critical protection against heat and open flames. Both materials are integral in safety gear, with Kevlar excelling in abrasion and ballistic protection, while Nomex offers enhanced fire retardancy and comfort under high-temperature conditions.

Comfort and Wearability Factors

Kevlar lining offers exceptional durability and abrasion resistance, making it ideal for high-impact environments, but it tends to be less breathable and slightly heavier compared to Nomex lining. Nomex lining excels in comfort and wearability due to its superior moisture-wicking properties and lighter weight, enhancing heat and flame resistance while maintaining flexibility. Choosing between Kevlar and Nomex lining depends on prioritizing toughness over breathability or comfort in protective gear applications.

Maintenance and Care Requirements

Kevlar lining demands careful maintenance to preserve its high tensile strength and abrasion resistance, requiring gentle washing with mild detergents and avoiding high heat during drying to prevent fiber degradation. Nomex lining, known for its thermal stability and flame resistance, is easier to maintain as it tolerates higher washing temperatures but still requires avoiding harsh chemicals that can impair its protective properties. Both materials benefit from regular inspections for wear and damage to ensure optimal performance in protective applications.

Cost Comparison: Kevlar vs Nomex Linings

Kevlar linings generally incur higher material costs compared to Nomex linings due to Kevlar's superior tensile strength and durability. Nomex linings offer a more cost-effective solution, balancing fire resistance and affordability without compromising safety standards. Organizations must weigh long-term investment benefits of Kevlar's superior abrasion resistance against Nomex's lower upfront expenditure.

Choosing the Right Lining for Your Needs

Kevlar lining offers superior cut and abrasion resistance, making it ideal for industries requiring high durability and protection against sharp objects. Nomex lining provides enhanced flame resistance and thermal stability, favored in firefighting and electrical applications where heat exposure is critical. Selecting the right lining depends on assessing the primary hazards, with Kevlar suited for mechanical risks and Nomex optimized for thermal and fire protection needs.

Kevlar lining vs Nomex lining Infographic

materialdif.com

materialdif.com