Kevlar sheets offer a flat, durable surface ideal for protective applications requiring resistance to cuts, punctures, and abrasion, while Kevlar ropes provide exceptional tensile strength and flexibility for securing and lifting heavy loads. The sheet's uniform structure ensures consistent protection, whereas ropes deliver versatility in knots and dynamic movement. Choosing between Kevlar sheet and rope depends on whether you need rigid defense or reliable, flexible support.

Table of Comparison

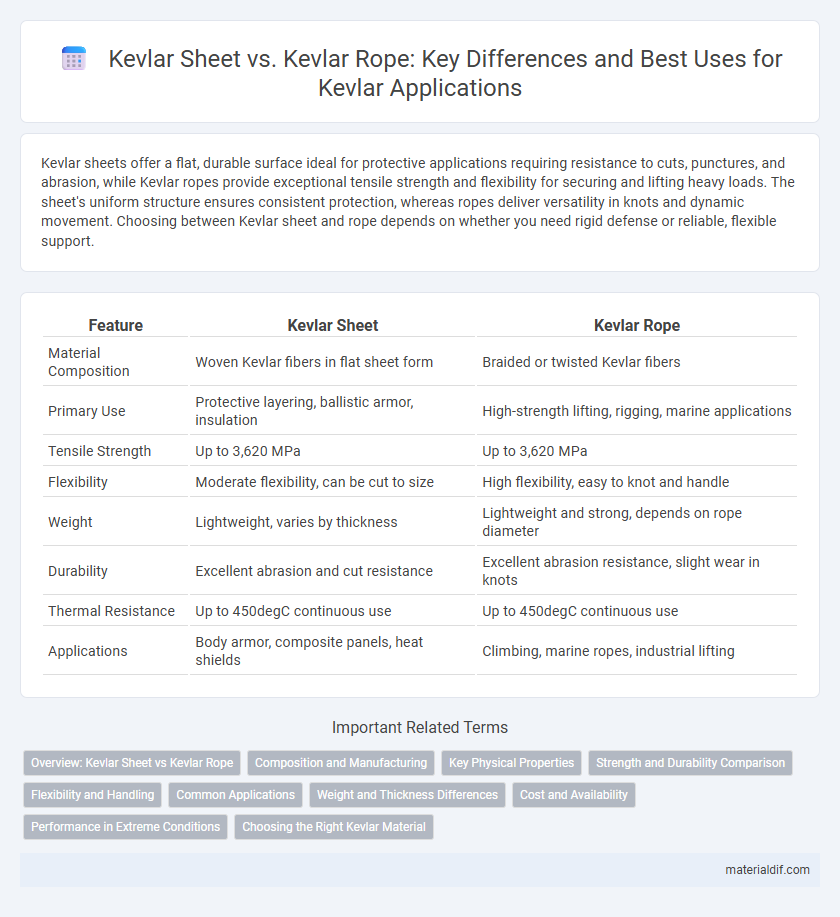

| Feature | Kevlar Sheet | Kevlar Rope |

|---|---|---|

| Material Composition | Woven Kevlar fibers in flat sheet form | Braided or twisted Kevlar fibers |

| Primary Use | Protective layering, ballistic armor, insulation | High-strength lifting, rigging, marine applications |

| Tensile Strength | Up to 3,620 MPa | Up to 3,620 MPa |

| Flexibility | Moderate flexibility, can be cut to size | High flexibility, easy to knot and handle |

| Weight | Lightweight, varies by thickness | Lightweight and strong, depends on rope diameter |

| Durability | Excellent abrasion and cut resistance | Excellent abrasion resistance, slight wear in knots |

| Thermal Resistance | Up to 450degC continuous use | Up to 450degC continuous use |

| Applications | Body armor, composite panels, heat shields | Climbing, marine ropes, industrial lifting |

Overview: Kevlar Sheet vs Kevlar Rope

Kevlar sheets offer high tensile strength and lightweight protection, making them ideal for ballistic armor and impact-resistant applications. Kevlar ropes provide superior abrasion resistance and exceptional tensile strength for heavy lifting and safety harnesses, excelling in flexibility and durability under load. Both products utilize para-aramid fibers but differ in form and specific use cases, optimizing performance according to structural requirements.

Composition and Manufacturing

Kevlar sheets are composed of tightly woven aramid fibers creating a flat, rigid material ideal for ballistic protection and structural reinforcement, produced through a controlled weaving process followed by heat treatment to enhance durability. Kevlar ropes consist of untwisted or braided aramid fibers designed to provide exceptional tensile strength and flexibility, manufactured by spinning and braiding techniques that optimize fiber alignment for load-bearing applications. Both forms utilize the inherent molecular structure of Kevlar, characterized by aromatic polyamide chains, but differ in fabrication methods that tailor their mechanical properties to specific uses.

Key Physical Properties

Kevlar sheets exhibit exceptional tensile strength, high modulus of elasticity, and superior resistance to abrasion, making them ideal for protective clothing and structural applications. Kevlar ropes, while also strong and durable, prioritize flexibility, impact resistance, and excellent fatigue life for use in demanding environments such as marine and climbing activities. The key physical properties differentiating Kevlar sheets from Kevlar ropes include stiffness, elongation at break, and surface texture, with sheets providing rigidity and ropes offering more dynamic load-bearing capabilities.

Strength and Durability Comparison

Kevlar sheets offer superior tensile strength and consistent durability across flat surfaces, making them ideal for protective gear and structural reinforcements. Kevlar ropes excel in dynamic load-bearing applications due to their flexibility and resistance to abrasion, ensuring long-lasting performance under tension. Both materials utilize Kevlar's high strength-to-weight ratio, but sheets deliver uniform strength while ropes provide enhanced flexibility and impact resistance.

Flexibility and Handling

Kevlar sheets offer superior flexibility for contouring and wrapping applications, maintaining high tensile strength while allowing ease of manipulation. Kevlar ropes prioritize durability and load-bearing capacity, but their braided structure can limit flexibility and increase stiffness during handling. Choosing between Kevlar sheet and rope depends on the need for pliability versus tensile performance in dynamic or static environments.

Common Applications

Kevlar sheets are commonly used in ballistic armor, protective clothing, and reinforcement in automotive and aerospace components due to their high tensile strength and flexibility. Kevlar ropes find widespread application in marine environments, climbing, rescue operations, and industrial lifting because of their excellent resistance to abrasion and low stretch properties. Both forms leverage Kevlar's lightweight yet durable characteristics to enhance safety and performance across diverse industries.

Weight and Thickness Differences

Kevlar sheets are designed with uniform thickness, typically ranging from 0.5 mm to 5 mm, providing a lightweight yet rigid material ideal for protective layering. Kevlar ropes vary in diameter, usually between 4 mm and 20 mm, resulting in greater thickness and weight to ensure high tensile strength and flexibility for load-bearing applications. The density of Kevlar (approximately 1.44 g/cm3) allows sheets to maintain lower overall weight compared to ropes of equivalent strength due to their flat, thin profile versus the bulkier, cylindrical structure of ropes.

Cost and Availability

Kevlar sheets are generally more expensive than Kevlar ropes due to their manufacturing complexity and the material's thickness uniformity requirements. Kevlar ropes are widely available in various thicknesses and lengths, making them cost-effective for applications needing flexibility and tensile strength. Bulk purchasing options for Kevlar ropes often reduce overall costs, whereas Kevlar sheets typically have limited suppliers and higher price points.

Performance in Extreme Conditions

Kevlar sheets offer superior impact resistance and high tensile strength, making them ideal for protective armor and structural reinforcement in extreme conditions. Kevlar ropes provide exceptional flexibility and durability under dynamic loads, excelling in applications requiring strong, lightweight tensile elements exposed to abrasion and harsh weather. Performance in extreme environments depends on material form: sheets maintain rigid protection, while ropes optimize strength and flexibility for high-stress, fluctuating forces.

Choosing the Right Kevlar Material

Kevlar sheets offer flat, flexible, and durable protection ideal for armor plating, gaskets, and impact-resistant panels. Kevlar ropes provide exceptional tensile strength, abrasion resistance, and flexibility, making them perfect for lifting, climbing, and marine applications. Selecting the right Kevlar material depends on the specific application's need for shape, strength orientation, and environmental exposure.

Kevlar Sheet vs Kevlar Rope Infographic

materialdif.com

materialdif.com