Kevlar honeycomb offers superior impact resistance and energy absorption compared to aluminum honeycomb, making it ideal for applications requiring lightweight durability. Its exceptional strength-to-weight ratio enhances structural performance while reducing overall weight. Kevlar honeycomb also provides better corrosion resistance and flexibility, extending the lifespan of pet-related products.

Table of Comparison

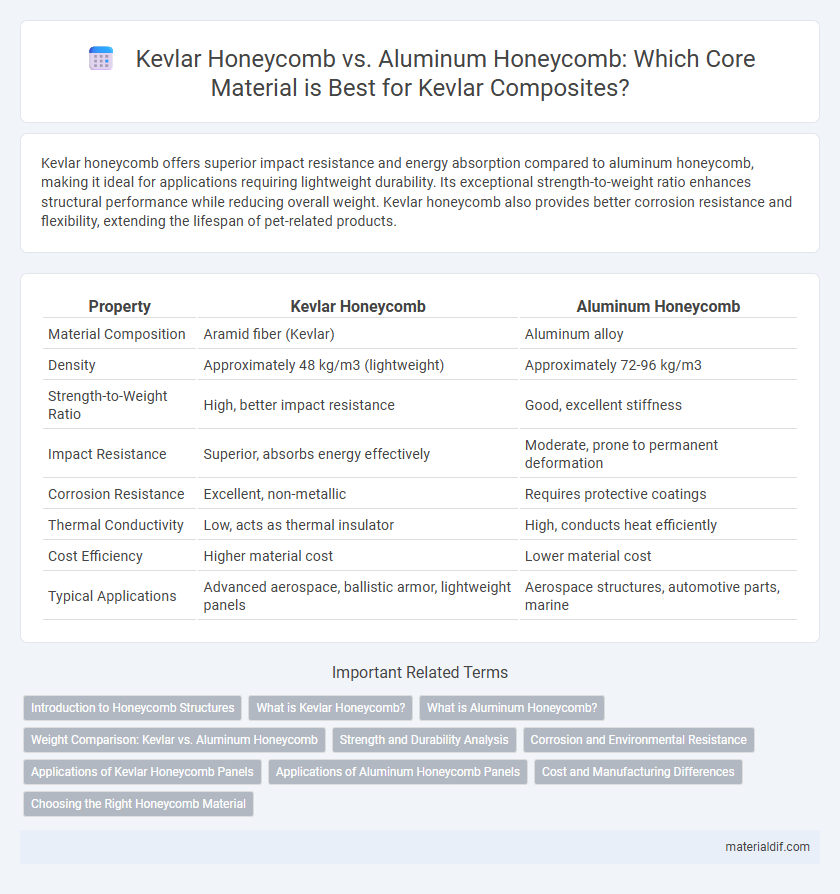

| Property | Kevlar Honeycomb | Aluminum Honeycomb |

|---|---|---|

| Material Composition | Aramid fiber (Kevlar) | Aluminum alloy |

| Density | Approximately 48 kg/m3 (lightweight) | Approximately 72-96 kg/m3 |

| Strength-to-Weight Ratio | High, better impact resistance | Good, excellent stiffness |

| Impact Resistance | Superior, absorbs energy effectively | Moderate, prone to permanent deformation |

| Corrosion Resistance | Excellent, non-metallic | Requires protective coatings |

| Thermal Conductivity | Low, acts as thermal insulator | High, conducts heat efficiently |

| Cost Efficiency | Higher material cost | Lower material cost |

| Typical Applications | Advanced aerospace, ballistic armor, lightweight panels | Aerospace structures, automotive parts, marine |

Introduction to Honeycomb Structures

Kevlar honeycomb structures offer superior impact resistance and energy absorption compared to aluminum honeycomb, making them ideal for aerospace and automotive applications requiring lightweight yet durable materials. Kevlar's high tensile strength and low density contribute to enhanced structural performance while reducing overall weight. Unlike aluminum honeycombs, Kevlar exhibits improved fatigue resistance and corrosion immunity, extending component lifespan under cyclic loading conditions.

What is Kevlar Honeycomb?

Kevlar honeycomb is a lightweight, high-strength material made from woven aramid fibers, forming a hexagonal structure known for its excellent impact resistance and energy absorption. It offers superior durability and corrosion resistance compared to aluminum honeycomb, making it ideal for aerospace, automotive, and protective equipment applications. The Kevlar honeycomb's enhanced toughness and low density provide improved performance in vibration damping and structural reinforcement, outperforming traditional aluminum counterparts.

What is Aluminum Honeycomb?

Aluminum honeycomb is a lightweight core material made from thin aluminum foils bonded together in a hexagonal pattern, delivering high strength-to-weight ratio and excellent energy absorption properties. It offers superior stiffness and impact resistance, commonly used in aerospace, automotive, and marine industries for structural panels and sandwich composites. Compared to Kevlar honeycomb, aluminum honeycomb provides better thermal conductivity and can withstand higher temperatures but typically weighs more and has less vibration damping capability.

Weight Comparison: Kevlar vs. Aluminum Honeycomb

Kevlar honeycomb offers a significant weight advantage over aluminum honeycomb, with densities typically around 1.44 g/cm3 compared to aluminum's 2.7 g/cm3. This weight reduction translates to improved fuel efficiency and performance in aerospace and automotive applications where lightweight materials are critical. Despite being lighter, Kevlar honeycomb maintains excellent strength-to-weight ratio and impact resistance, making it a preferred choice in weight-sensitive structural components.

Strength and Durability Analysis

Kevlar honeycomb exhibits superior strength-to-weight ratio and exceptional impact resistance compared to aluminum honeycomb, making it ideal for high-performance applications. Its polymer-based structure provides enhanced durability against fatigue and corrosion, ensuring longer lifespan under harsh environmental conditions. Aluminum honeycomb, while offering good compressive strength, tends to suffer from corrosion and reduced fatigue life in moist or corrosive settings.

Corrosion and Environmental Resistance

Kevlar honeycomb offers superior corrosion resistance compared to aluminum honeycomb, as it is inherently immune to moisture and chemical exposure that typically degrade metals. Its synthetic fiber composition prevents oxidation and corrosion-related structural weakening often observed in aluminum cores. Kevlar honeycomb's enhanced environmental durability makes it ideal for applications in harsh or marine environments where aluminum honeycomb would require protective coatings or frequent maintenance.

Applications of Kevlar Honeycomb Panels

Kevlar honeycomb panels provide exceptional impact resistance and energy absorption, making them ideal for aerospace, automotive, and ballistic protection applications where weight reduction and durability are critical. Unlike aluminum honeycomb, Kevlar's superior toughness and vibration damping enhance safety in helmets, body armor, and crash structures. These panels are preferred in high-performance industries requiring lightweight materials combined with superior mechanical properties.

Applications of Aluminum Honeycomb Panels

Aluminum honeycomb panels are widely used in aerospace, automotive, and construction industries due to their high strength-to-weight ratio, corrosion resistance, and excellent energy absorption capabilities. These panels provide superior structural support in aircraft floors, spacecraft components, and lightweight vehicle bodies, enhancing fuel efficiency and durability. Their fire resistance and recyclability make aluminum honeycomb panels a sustainable choice for modern engineering applications.

Cost and Manufacturing Differences

Kevlar honeycomb offers superior strength-to-weight ratio compared to aluminum honeycomb, but its raw materials and manufacturing processes make it significantly more expensive. Unlike aluminum, Kevlar honeycomb requires specialized resin infusion and curing techniques, leading to longer production times and higher labor costs. Aluminum honeycomb benefits from simpler, highly automated fabrication methods, resulting in lower material and manufacturing expenses.

Choosing the Right Honeycomb Material

Kevlar honeycomb offers superior impact resistance and energy absorption compared to aluminum honeycomb, making it ideal for applications requiring enhanced durability and lightweight performance, such as aerospace and military armor. Aluminum honeycomb provides excellent stiffness and thermal conductivity, preferred in structural components where weight savings and heat dissipation are critical. Selecting the right honeycomb material depends on balancing factors like mechanical strength, weight optimization, environmental resistance, and specific application requirements.

Kevlar honeycomb vs Aluminum honeycomb Infographic

materialdif.com

materialdif.com