Kevlar reinforcement offers superior flexibility and lighter weight compared to traditional steel reinforcement, making it ideal for pet safety gear such as harnesses and collars. Its high tensile strength provides excellent durability and resistance to wear and tear, ensuring long-lasting protection without compromising comfort. Unlike steel, Kevlar does not rust or corrode, enhancing the longevity and maintenance of pet accessories.

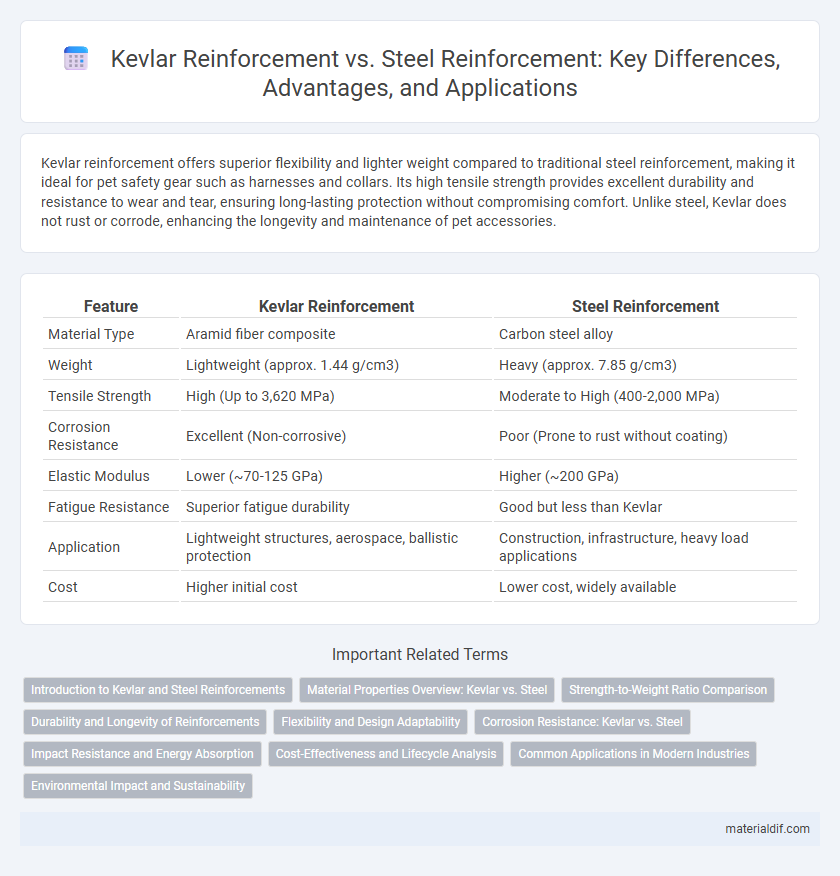

Table of Comparison

| Feature | Kevlar Reinforcement | Steel Reinforcement |

|---|---|---|

| Material Type | Aramid fiber composite | Carbon steel alloy |

| Weight | Lightweight (approx. 1.44 g/cm3) | Heavy (approx. 7.85 g/cm3) |

| Tensile Strength | High (Up to 3,620 MPa) | Moderate to High (400-2,000 MPa) |

| Corrosion Resistance | Excellent (Non-corrosive) | Poor (Prone to rust without coating) |

| Elastic Modulus | Lower (~70-125 GPa) | Higher (~200 GPa) |

| Fatigue Resistance | Superior fatigue durability | Good but less than Kevlar |

| Application | Lightweight structures, aerospace, ballistic protection | Construction, infrastructure, heavy load applications |

| Cost | Higher initial cost | Lower cost, widely available |

Introduction to Kevlar and Steel Reinforcements

Kevlar reinforcement offers high tensile strength and lightweight properties compared to traditional steel reinforcement, making it ideal for applications requiring corrosion resistance and weight reduction. Steel reinforcement, widely used in construction, provides excellent compressive strength and durability but is prone to corrosion, increasing maintenance costs over time. Kevlar's polymer-based structure enhances flexibility and impact resistance, contrasting with steel's rigid metallic composition.

Material Properties Overview: Kevlar vs. Steel

Kevlar exhibits a significantly higher tensile strength-to-weight ratio compared to steel, making it lighter yet exceptionally strong for reinforcing applications. Its corrosion resistance and flexibility outperform steel, which is prone to rust and has a higher density that adds weight. Steel offers superior compressive strength and heat resistance, but Kevlar's impact resistance and fatigue durability provide enhanced performance in dynamic loading conditions.

Strength-to-Weight Ratio Comparison

Kevlar reinforcement offers a significantly higher strength-to-weight ratio compared to steel reinforcement, making it ideal for applications requiring lightweight yet durable materials. Kevlar's tensile strength reaches up to 3,620 MPa, while steel averages around 1,550 MPa, allowing structures to maintain integrity with less mass. This superior efficiency reduces overall weight without compromising performance in aerospace, automotive, and civil engineering industries.

Durability and Longevity of Reinforcements

Kevlar reinforcement offers superior durability compared to steel reinforcement due to its high resistance to corrosion, chemical damage, and fatigue, resulting in a significantly extended service life. Unlike steel, Kevlar maintains its structural integrity in harsh environmental conditions, minimizing maintenance needs and overall lifecycle costs. Its lightweight nature also reduces stress on structures, further enhancing longevity and performance over time.

Flexibility and Design Adaptability

Kevlar reinforcement offers superior flexibility compared to steel reinforcement, allowing for more intricate and lightweight design possibilities in various engineering applications. Its high tensile strength-to-weight ratio enables the creation of complex shapes without compromising structural integrity. Kevlar's adaptability supports innovative architectural and industrial designs that require enhanced performance and durability.

Corrosion Resistance: Kevlar vs. Steel

Kevlar reinforcement exhibits superior corrosion resistance compared to steel reinforcement, making it ideal for structures exposed to harsh environmental conditions. Unlike steel, Kevlar does not rust or degrade when exposed to moisture, chemicals, or saltwater, significantly extending the lifespan of reinforced concrete and composite materials. This corrosion resistance reduces maintenance costs and enhances the durability of infrastructure in marine, chemical, and underground applications.

Impact Resistance and Energy Absorption

Kevlar reinforcement exhibits superior impact resistance compared to steel reinforcement due to its high tensile strength-to-weight ratio and exceptional flexibility, allowing it to absorb and dissipate energy more efficiently during collisions. Kevlar fibers deform elastically under impact, reducing the risk of catastrophic failure, whereas steel reinforcement tends to undergo plastic deformation, leading to potential structural damage. The enhanced energy absorption capacity of Kevlar makes it ideal for applications requiring lightweight yet durable materials capable of mitigating high-impact forces.

Cost-Effectiveness and Lifecycle Analysis

Kevlar reinforcement offers significant cost-effectiveness over steel reinforcement by reducing maintenance expenses due to its corrosion resistance and lighter weight, which lowers transportation and installation costs. Lifecycle analysis reveals Kevlar's durability in harsh environments extends structural lifespan, minimizing repair frequency and overall project expenditures. Compared to steel, Kevlar's high strength-to-weight ratio and resistance to fatigue enhance long-term economic benefits in infrastructure and composite applications.

Common Applications in Modern Industries

Kevlar reinforcement is widely used in aerospace, automotive, and sports equipment industries due to its high tensile strength-to-weight ratio, providing lightweight yet durable solutions. Unlike steel reinforcement, Kevlar offers superior corrosion resistance and flexibility, making it ideal for applications requiring impact resistance and vibration damping. Common industries deploying Kevlar composites include aviation for aircraft panels, automotive manufacturing for body panels and brake pads, and sporting goods like helmets and protective gear.

Environmental Impact and Sustainability

Kevlar reinforcement offers a significantly lower environmental impact compared to steel reinforcement due to its lightweight nature, which reduces transportation emissions and energy consumption during installation. Kevlar's high strength-to-weight ratio enhances structural efficiency, leading to less material usage and waste generation throughout the lifecycle of construction projects. Unlike steel, Kevlar does not corrode, minimizing maintenance needs and extending the durability of reinforced structures, contributing to long-term sustainability in infrastructure development.

Kevlar reinforcement vs Steel reinforcement Infographic

materialdif.com

materialdif.com