Kevlar sheets offer exceptional tensile strength while being significantly lighter than steel sheets, making them ideal for applications requiring high durability without added weight. Their impact resistance and flexibility surpass steel, providing better protection in dynamic environments. Unlike steel, Kevlar sheets resist corrosion and are easier to handle, enhancing their practical use in pet safety gear.

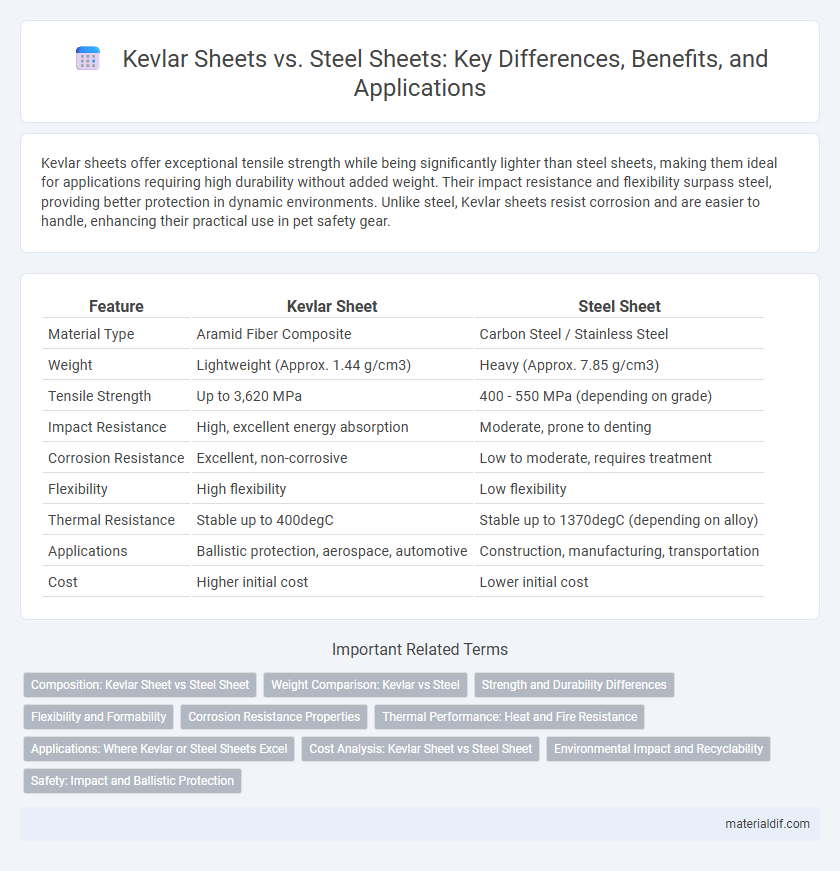

Table of Comparison

| Feature | Kevlar Sheet | Steel Sheet |

|---|---|---|

| Material Type | Aramid Fiber Composite | Carbon Steel / Stainless Steel |

| Weight | Lightweight (Approx. 1.44 g/cm3) | Heavy (Approx. 7.85 g/cm3) |

| Tensile Strength | Up to 3,620 MPa | 400 - 550 MPa (depending on grade) |

| Impact Resistance | High, excellent energy absorption | Moderate, prone to denting |

| Corrosion Resistance | Excellent, non-corrosive | Low to moderate, requires treatment |

| Flexibility | High flexibility | Low flexibility |

| Thermal Resistance | Stable up to 400degC | Stable up to 1370degC (depending on alloy) |

| Applications | Ballistic protection, aerospace, automotive | Construction, manufacturing, transportation |

| Cost | Higher initial cost | Lower initial cost |

Composition: Kevlar Sheet vs Steel Sheet

Kevlar sheets consist of aramid fibers characterized by high tensile strength and low weight, while steel sheets are composed primarily of iron alloyed with carbon, providing exceptional hardness and density. Kevlar's molecular structure features long chains of poly-paraphenylene terephthalamide, contributing to its durability and impact resistance, contrasting with steel's crystalline metal lattice that enhances its rigidity and thermal conductivity. The choice between Kevlar and steel sheets depends on application needs like weight reduction, flexibility, and resistance to corrosion versus strength and load-bearing capacity.

Weight Comparison: Kevlar vs Steel

Kevlar sheets offer a significant weight advantage over steel sheets, with Kevlar being approximately five times lighter while maintaining comparable tensile strength. This substantial weight difference makes Kevlar sheets ideal for applications requiring high strength-to-weight ratios, such as aerospace and military armor. Steel sheets, although heavier, provide superior rigidity and impact resistance but at the cost of increased weight and reduced maneuverability.

Strength and Durability Differences

Kevlar sheets exhibit superior tensile strength and impact resistance compared to steel sheets, making them ideal for applications requiring lightweight yet highly durable materials. While steel sheets offer excellent compressive strength and resistance to deformation, Kevlar's molecular structure provides exceptional energy absorption and resistance to fatigue. This durability makes Kevlar sheets preferable in environments with repeated impacts or harsh conditions where steel may corrode or deform.

Flexibility and Formability

Kevlar sheets exhibit superior flexibility and formability compared to steel sheets, allowing them to be easily molded into complex shapes without cracking or losing strength. The high tensile strength-to-weight ratio of Kevlar enables lightweight, durable components that maintain structural integrity under bending and deformation. Unlike rigid steel sheets, Kevlar sheets offer enhanced impact resistance while providing greater ease of fabrication in custom applications.

Corrosion Resistance Properties

Kevlar sheets exhibit exceptional corrosion resistance compared to steel sheets, as they are inherently immune to rust, oxidation, and chemical degradation. Steel sheets, unless specially treated or coated, tend to corrode when exposed to moisture, salts, and harsh environmental conditions, reducing their lifespan. Kevlar's resistance to chemical agents and environmental factors makes it a superior choice for applications where corrosion is a critical concern.

Thermal Performance: Heat and Fire Resistance

Kevlar sheets offer superior heat and fire resistance compared to steel sheets, maintaining structural integrity at temperatures up to 800degF (427degC) without melting or losing strength. Steel sheets, while strong, conduct heat rapidly and can weaken or warp at temperatures above 1,200degF (649degC), making them less effective in high-heat applications. Kevlar's low thermal conductivity and flame-retardant properties provide enhanced thermal performance in environments exposed to extreme heat or fire hazards.

Applications: Where Kevlar or Steel Sheets Excel

Kevlar sheets excel in aerospace and ballistic applications due to their high tensile strength-to-weight ratio and exceptional impact resistance, making them ideal for body armor and lightweight vehicle panels. Steel sheets dominate in construction and heavy machinery industries, offering superior compressive strength, durability, and cost-effectiveness for structural frameworks and industrial equipment. Both materials are critical in marine engineering, with Kevlar providing corrosion resistance and flexibility, while steel delivers robustness and load-bearing capacity.

Cost Analysis: Kevlar Sheet vs Steel Sheet

Kevlar sheets generally have a higher upfront material cost compared to steel sheets due to their advanced polymer composition and specialized manufacturing process. However, Kevlar's lightweight nature and superior strength-to-weight ratio can reduce overall costs in applications requiring weight savings, such as automotive and aerospace industries. Steel sheets remain more cost-effective for bulk structural use, but the long-term benefits of reduced maintenance and improved durability often justify the premium price of Kevlar in high-performance environments.

Environmental Impact and Recyclability

Kevlar sheets offer a significantly lower environmental impact compared to steel sheets due to their lightweight nature, which reduces energy consumption during transportation and manufacturing. Unlike steel, Kevlar recycling remains challenging, as current technologies for reprocessing aramid fibers are limited and less developed. Steel sheets benefit from well-established recycling infrastructure, enabling efficient material recovery and minimizing landfill waste, but their higher energy-intensive production contributes to greater carbon emissions.

Safety: Impact and Ballistic Protection

Kevlar sheets provide superior impact and ballistic protection compared to steel sheets due to their high tensile strength and energy-absorbing fibers, which effectively dissipate the force of projectiles and blunt impacts. Unlike steel, Kevlar's lightweight and flexible structure reduce blunt force trauma and penetration risk, enhancing safety in personal armor and vehicle applications. Steel sheets offer rigidity and resistance but lack the same level of impact energy dispersion and can cause greater injury upon impact due to their weight and inflexibility.

Kevlar sheet vs Steel sheet Infographic

materialdif.com

materialdif.com