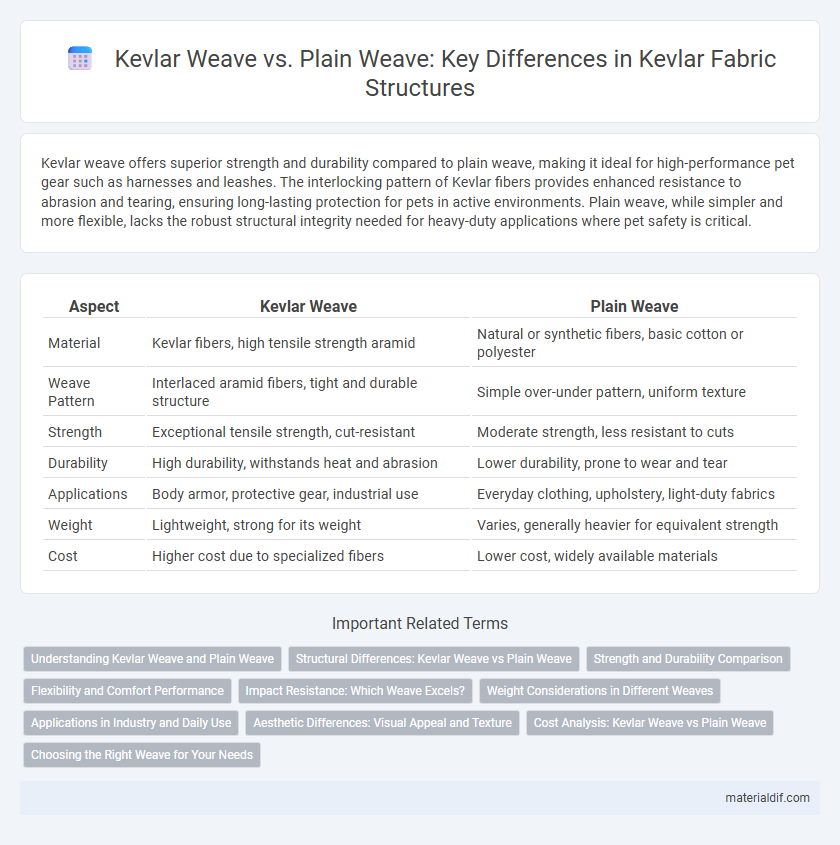

Kevlar weave offers superior strength and durability compared to plain weave, making it ideal for high-performance pet gear such as harnesses and leashes. The interlocking pattern of Kevlar fibers provides enhanced resistance to abrasion and tearing, ensuring long-lasting protection for pets in active environments. Plain weave, while simpler and more flexible, lacks the robust structural integrity needed for heavy-duty applications where pet safety is critical.

Table of Comparison

| Aspect | Kevlar Weave | Plain Weave |

|---|---|---|

| Material | Kevlar fibers, high tensile strength aramid | Natural or synthetic fibers, basic cotton or polyester |

| Weave Pattern | Interlaced aramid fibers, tight and durable structure | Simple over-under pattern, uniform texture |

| Strength | Exceptional tensile strength, cut-resistant | Moderate strength, less resistant to cuts |

| Durability | High durability, withstands heat and abrasion | Lower durability, prone to wear and tear |

| Applications | Body armor, protective gear, industrial use | Everyday clothing, upholstery, light-duty fabrics |

| Weight | Lightweight, strong for its weight | Varies, generally heavier for equivalent strength |

| Cost | Higher cost due to specialized fibers | Lower cost, widely available materials |

Understanding Kevlar Weave and Plain Weave

Kevlar weave features a distinctive interlacing pattern that enhances tensile strength and impact resistance, making it ideal for body armor and protective gear applications. Plain weave, characterized by its simple over-under pattern, provides uniform strength and greater dimensional stability, suitable for lightweight composite materials. Understanding the structural differences between Kevlar weave and plain weave is crucial for selecting the appropriate fabric in high-performance environments.

Structural Differences: Kevlar Weave vs Plain Weave

Kevlar weave features interlaced aramid fibers arranged in a tight, basket-like pattern that enhances tensile strength and impact resistance compared to the simpler over-under pattern of plain weave, which offers less flexibility and durability. The structural complexity of Kevlar weave allows for greater energy absorption and distribution, making it ideal for ballistic and protective applications. Plain weave, by contrast, provides a uniform surface but lacks the enhanced mechanical properties necessary for high-performance protective materials.

Strength and Durability Comparison

Kevlar weave significantly outperforms plain weave in strength due to its tightly interlaced aramid fibers, providing superior tensile strength and impact resistance ideal for ballistic protection and industrial applications. The unique honeycomb structure of Kevlar weave distributes stress more evenly, enhancing durability and reducing the likelihood of fiber breakage under high strain. In contrast, plain weave offers less resistance to tearing and abrasion, making it less suitable for demanding safety and performance requirements.

Flexibility and Comfort Performance

Kevlar weave offers enhanced flexibility due to its interlaced yarns, allowing garments to adapt more easily to body movements while maintaining high tensile strength. In contrast, plain weave Kevlar is stiffer and provides less comfort, making it suitable for applications requiring maximum durability but limited flexibility. Choosing Kevlar weave improves comfort performance in protective clothing by balancing flexibility with abrasion resistance.

Impact Resistance: Which Weave Excels?

Kevlar weave offers superior impact resistance compared to plain weave due to its distinctive pattern that distributes force more evenly across the fibers. The interlacing structure of Kevlar weave minimizes fiber movement, reducing the risk of breakage under high-stress impacts. This enhanced energy absorption makes Kevlar weave the preferred choice in applications demanding exceptional protective performance.

Weight Considerations in Different Weaves

Kevlar weave offers a balanced weight-to-strength ratio, making it ideal for applications requiring high impact resistance without excessive bulk. Plain weave Kevlar tends to be heavier due to its tighter interlacing pattern, which increases material density and overall fabric thickness. Weight considerations are critical in optimizing performance, as Kevlar weave minimizes weight while maintaining protective properties, benefiting industries like aerospace and personal armor.

Applications in Industry and Daily Use

Kevlar weave offers superior tensile strength and flexibility, making it ideal for ballistic armor, protective gloves, and high-performance sporting goods. Plain weave Kevlar provides excellent abrasion resistance and stability, commonly used in industrial belts, ropes, and protective clothing. Both weaves enhance safety and durability across automotive, aerospace, and personal safety equipment industries.

Aesthetic Differences: Visual Appeal and Texture

Kevlar weave features a distinctive pattern with interlaced fibers creating a textured, visually dynamic surface that enhances the fabric's depth and complexity. Plain weave Kevlar offers a uniform, smooth appearance with a tight, grid-like pattern that provides a classic, minimalist aesthetic. The choice between Kevlar weave and plain weave significantly impacts the fabric's visual appeal and tactile experience, influencing applications where both functionality and design are critical.

Cost Analysis: Kevlar Weave vs Plain Weave

Kevlar weave typically incurs higher costs than plain weave due to its complex interlacing pattern designed for enhanced strength and durability in applications like ballistic protection and aerospace. Plain weave offers a more economical option with simpler production processes, making it suitable for general-purpose textiles and less demanding structural requirements. The cost differential reflects the balance between performance benefits of Kevlar weave and the manufacturing efficiency of plain weave fabrics.

Choosing the Right Weave for Your Needs

Kevlar weave offers superior tensile strength and puncture resistance compared to plain weave, making it ideal for applications requiring enhanced durability, such as ballistic protection and industrial gloves. Plain weave Kevlar provides better flexibility and lighter weight, suitable for less intense uses like protective clothing and lightweight composites. Selecting the right Kevlar weave depends on balancing strength requirements with flexibility and weight considerations specific to your project's performance demands.

Kevlar Weave vs Plain Weave Infographic

materialdif.com

materialdif.com