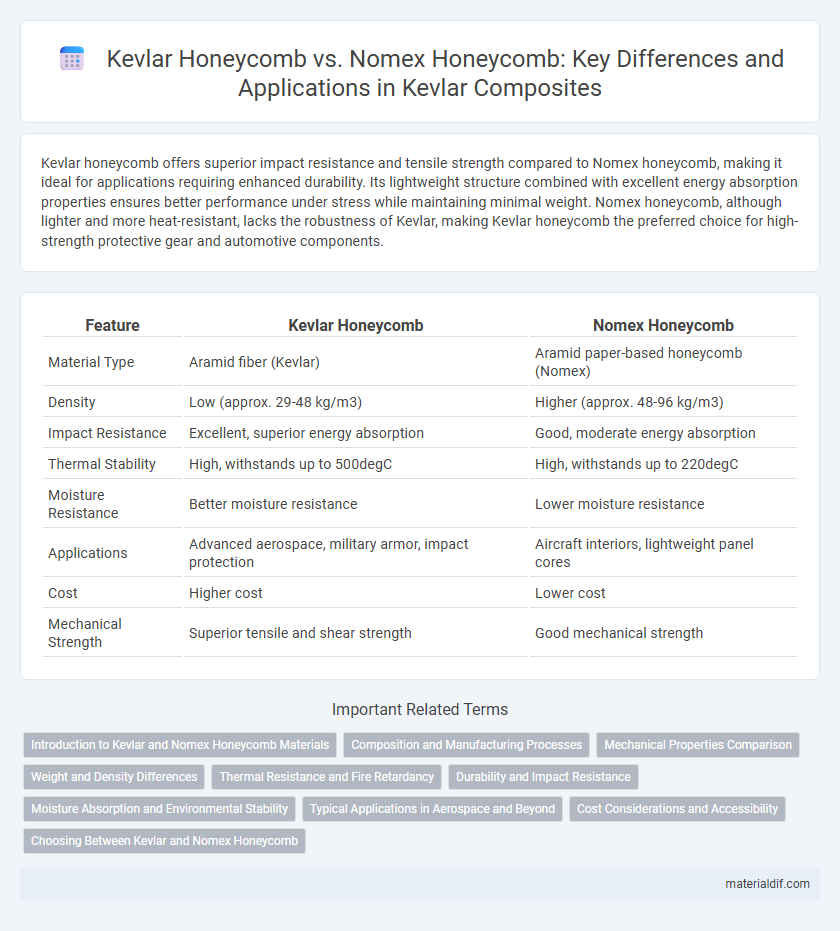

Kevlar honeycomb offers superior impact resistance and tensile strength compared to Nomex honeycomb, making it ideal for applications requiring enhanced durability. Its lightweight structure combined with excellent energy absorption properties ensures better performance under stress while maintaining minimal weight. Nomex honeycomb, although lighter and more heat-resistant, lacks the robustness of Kevlar, making Kevlar honeycomb the preferred choice for high-strength protective gear and automotive components.

Table of Comparison

| Feature | Kevlar Honeycomb | Nomex Honeycomb |

|---|---|---|

| Material Type | Aramid fiber (Kevlar) | Aramid paper-based honeycomb (Nomex) |

| Density | Low (approx. 29-48 kg/m3) | Higher (approx. 48-96 kg/m3) |

| Impact Resistance | Excellent, superior energy absorption | Good, moderate energy absorption |

| Thermal Stability | High, withstands up to 500degC | High, withstands up to 220degC |

| Moisture Resistance | Better moisture resistance | Lower moisture resistance |

| Applications | Advanced aerospace, military armor, impact protection | Aircraft interiors, lightweight panel cores |

| Cost | Higher cost | Lower cost |

| Mechanical Strength | Superior tensile and shear strength | Good mechanical strength |

Introduction to Kevlar and Nomex Honeycomb Materials

Kevlar honeycomb features high tensile strength and excellent impact resistance, making it ideal for applications requiring lightweight durability. Nomex honeycomb consists of a flame-resistant aramid paper, providing superior thermal insulation and electrical performance. Both materials offer unique advantages in aerospace and protective gear industries, with Kevlar emphasizing structural strength and Nomex enhancing fire resistance.

Composition and Manufacturing Processes

Kevlar honeycomb is composed of aramid fibers with high tensile strength and thermal stability, manufactured through a wet lay-up process that creates a rigid, lightweight cellular structure. Nomex honeycomb consists of meta-aramid fibers, produced by impregnating paper sheets with phenolic resin followed by a controlled curing process to form a strong, flame-resistant core. The differing fiber chemistry and resin systems result in variations in mechanical properties and thermal resistance essential for aerospace and industrial applications.

Mechanical Properties Comparison

Kevlar honeycomb exhibits superior impact resistance and tensile strength compared to Nomex honeycomb, making it ideal for applications requiring high energy absorption and durability. Nomex honeycomb, while offering excellent thermal stability and lightweight characteristics, generally has lower compressive strength and stiffness than Kevlar variants. These mechanical property differences influence material selection for aerospace and automotive components where performance under stress is critical.

Weight and Density Differences

Kevlar honeycomb exhibits a lower density of approximately 0.048 g/cm3 compared to Nomex honeycomb, which typically ranges around 0.073 g/cm3, resulting in a significant weight reduction in structural applications. The reduced weight of Kevlar honeycomb enhances fuel efficiency and payload capacity in aerospace and automotive industries. Despite its lighter weight, Kevlar maintains comparable mechanical strength and impact resistance, making it a favorable choice over Nomex in weight-sensitive designs.

Thermal Resistance and Fire Retardancy

Kevlar honeycomb exhibits superior thermal resistance due to its high heat tolerance and lower thermal conductivity compared to Nomex honeycomb, enabling better insulation under extreme temperature conditions. Kevlar's molecular structure provides enhanced fire retardancy, resisting ignition and flame spread more effectively than Nomex, which has higher flammability despite its excellent strength-to-weight ratio. These properties make Kevlar honeycomb a preferred choice in aerospace and automotive applications requiring robust fire protection and thermal stability.

Durability and Impact Resistance

Kevlar honeycomb structures exhibit superior durability and impact resistance compared to Nomex honeycomb, making them ideal for demanding aerospace and defense applications. Kevlar's high tensile strength and toughness provide enhanced energy absorption and resistance to penetration. In contrast, Nomex honeycomb offers lightweight properties but falls short in withstanding heavy impacts and prolonged mechanical stress.

Moisture Absorption and Environmental Stability

Kevlar honeycomb exhibits significantly lower moisture absorption compared to Nomex honeycomb, enhancing its durability in humid and wet environments. The chemical structure of Kevlar provides superior environmental stability, resisting degradation from UV exposure and chemical pollutants more effectively than Nomex. These properties make Kevlar honeycomb a preferred choice for aerospace and marine applications where moisture resistance and long-term stability are critical.

Typical Applications in Aerospace and Beyond

Kevlar honeycomb structures are widely used in aerospace for impact-resistant panels, helicopter rotor blades, and ballistic protection due to their exceptional tensile strength and energy absorption. Nomex honeycomb, favored for thermal insulation and fire resistance, is commonly applied in aircraft interiors, flooring, and nacelle liners where lightweight heat barriers are critical. Beyond aerospace, Kevlar honeycomb finds use in automotive racing and protective gear, while Nomex honeycomb supports applications in fireproof construction and industrial insulation.

Cost Considerations and Accessibility

Kevlar honeycomb offers high strength-to-weight ratio but tends to be more expensive due to complex manufacturing processes and limited suppliers, impacting cost-sensitive projects. Nomex honeycomb provides a cost-effective alternative with easier accessibility stemming from widespread production and lower raw material expenses. Choosing between Kevlar and Nomex honeycomb depends on balancing budget constraints with performance requirements in aerospace and defense applications.

Choosing Between Kevlar and Nomex Honeycomb

Kevlar honeycomb offers superior impact resistance and higher tensile strength compared to Nomex honeycomb, making it ideal for demanding aerospace and military applications. Nomex honeycomb provides enhanced fire resistance and lightweight durability, often preferred in thermal insulation and aircraft interiors. Selecting between Kevlar and Nomex honeycomb depends on prioritizing either mechanical strength for structural integrity or thermal stability for safety and weight considerations.

Kevlar honeycomb vs Nomex honeycomb Infographic

materialdif.com

materialdif.com