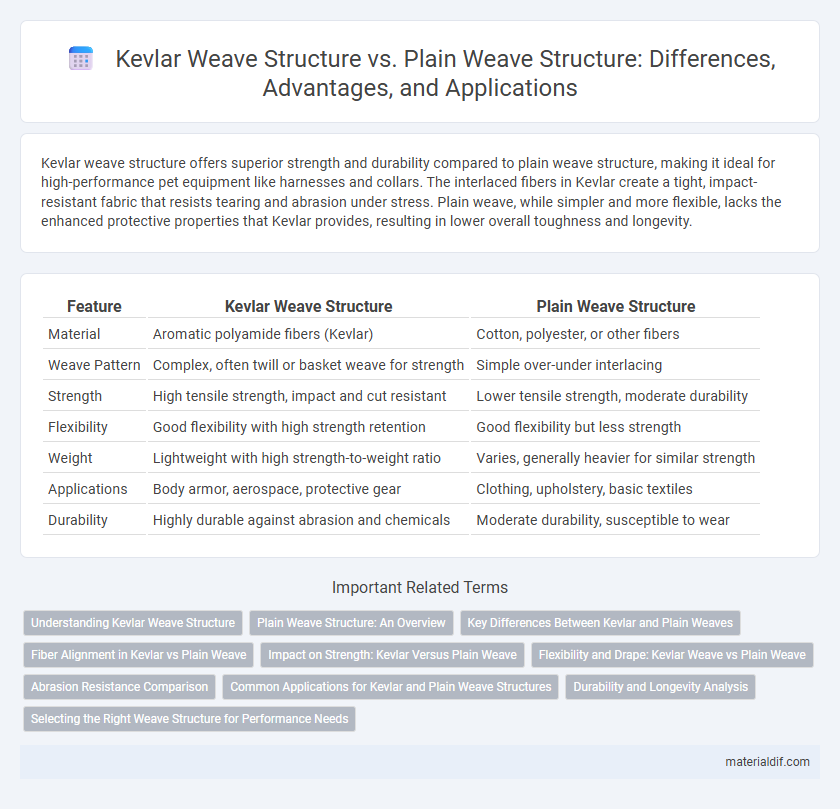

Kevlar weave structure offers superior strength and durability compared to plain weave structure, making it ideal for high-performance pet equipment like harnesses and collars. The interlaced fibers in Kevlar create a tight, impact-resistant fabric that resists tearing and abrasion under stress. Plain weave, while simpler and more flexible, lacks the enhanced protective properties that Kevlar provides, resulting in lower overall toughness and longevity.

Table of Comparison

| Feature | Kevlar Weave Structure | Plain Weave Structure |

|---|---|---|

| Material | Aromatic polyamide fibers (Kevlar) | Cotton, polyester, or other fibers |

| Weave Pattern | Complex, often twill or basket weave for strength | Simple over-under interlacing |

| Strength | High tensile strength, impact and cut resistant | Lower tensile strength, moderate durability |

| Flexibility | Good flexibility with high strength retention | Good flexibility but less strength |

| Weight | Lightweight with high strength-to-weight ratio | Varies, generally heavier for similar strength |

| Applications | Body armor, aerospace, protective gear | Clothing, upholstery, basic textiles |

| Durability | Highly durable against abrasion and chemicals | Moderate durability, susceptible to wear |

Understanding Kevlar Weave Structure

Kevlar weave structure features tightly interlaced fibers designed to maximize strength and flexibility, offering superior impact resistance compared to plain weave structures. Its unique pattern enhances ballistic protection by distributing force evenly across the material, making it ideal for body armor and aerospace applications. The robust interconnection of Kevlar fibers creates a lightweight yet highly durable fabric that outperforms traditional plain weaves in tensile strength and durability.

Plain Weave Structure: An Overview

Plain weave structure features a simple, over-and-under interlacing pattern of warp and weft fibers, offering excellent stability and uniform strength. In comparison to Kevlar's specialized weaves, plain weave provides consistent fabric density and is easier to produce, making it a common choice in various industrial textile applications. Its balanced construction ensures resistance to abrasion and minimizes distortion under stress, though it may lack the enhanced impact resistance characteristic of Kevlar-specific weave patterns.

Key Differences Between Kevlar and Plain Weaves

Kevlar weave structure features a unique interlacing pattern designed to maximize strength and impact resistance, making it ideal for ballistic applications and protective gear. In contrast, plain weave structure consists of a simple over-under pattern that offers balanced strength and flexibility but lacks the enhanced durability of Kevlar weaves. The key difference lies in Kevlar's ability to distribute force efficiently across its fibers due to its specialized weave, providing superior tensile strength compared to the uniform but less impact-resistant plain weave.

Fiber Alignment in Kevlar vs Plain Weave

Kevlar weave structure features highly aligned fibers that run parallel within each fiber bundle, enhancing tensile strength and impact resistance compared to the orthogonal fiber arrangement in plain weave structures. This alignment in Kevlar maximizes load distribution along the fiber length, providing superior mechanical performance and durability. Plain weave structures have fibers interlaced at right angles, resulting in less fiber alignment and reduced strength under directional stress.

Impact on Strength: Kevlar Versus Plain Weave

Kevlar weave structures exhibit superior impact resistance compared to plain weave structures due to their enhanced fiber orientation and tighter interlacing patterns, which distribute stress more effectively under high-impact conditions. The bi-directional Kevlar weave allows for greater energy absorption and tensile strength, making it ideal for ballistic and protective applications. In contrast, plain weave structures, while simpler and easier to manufacture, tend to have lower impact strength because their fibers interlace in a less optimized manner, resulting in decreased load distribution efficiency.

Flexibility and Drape: Kevlar Weave vs Plain Weave

Kevlar weave structures exhibit greater flexibility and superior drape compared to plain weave fabrics due to their unique interlacing patterns, which allow fibers to move more freely under tension. The enhanced pliability of Kevlar weaves improves conformability to complex shapes, making them ideal for protective apparel and flexible composite materials. In contrast, plain weave structures, characterized by tighter, crisper interlacing, offer less drape and reduced flexibility, leading to stiffer, more rigid textiles.

Abrasion Resistance Comparison

Kevlar weave structure offers superior abrasion resistance compared to plain weave structure due to its tightly interlaced, high-tenacity aramid fibers that distribute stress more evenly across the fabric. The enhanced fiber alignment and friction reduction in Kevlar weave minimize surface wear, making it ideal for high-impact and protective applications. In contrast, plain weave structure, with its simpler over-under pattern, typically exhibits lower durability under abrasive conditions, resulting in faster material degradation.

Common Applications for Kevlar and Plain Weave Structures

Kevlar weave structure, characterized by its tight, interlaced fibers, is commonly used in ballistic-resistant gear, such as bulletproof vests and helmets, due to its high tensile strength and impact resistance. Plain weave structures, featuring a simple over-under pattern, are widely applied in industrial fabrics, upholstery, and lightweight protective clothing, offering durability and flexibility. Kevlar's specialized weave enhances safety equipment performance, while plain weave remains preferred for general-purpose textiles requiring strength and stability.

Durability and Longevity Analysis

Kevlar weave structure features interlaced fibers in a complex pattern that enhances tensile strength and impact resistance compared to the simpler interlacing of plain weave structure. This intricate Kevlar weave distributes stress more evenly, significantly improving durability under mechanical strain and extending the material's lifespan in demanding applications. Longevity analysis shows Kevlar's weave maintains structural integrity better over time, resisting fraying and wear that commonly affect plain weave fabrics in high-stress environments.

Selecting the Right Weave Structure for Performance Needs

Kevlar weave structures provide enhanced tensile strength and abrasion resistance compared to plain weave structures, making them ideal for high-performance applications such as ballistic protection and aerospace components. The interlacing pattern in Kevlar weaves allows for better load distribution and flexibility, while plain weaves offer simplicity and cost-efficiency for less demanding uses. Selecting the right weave structure depends on the balance between required durability, weight, and flexibility for specific performance needs.

Kevlar weave structure vs Plain weave structure Infographic

materialdif.com

materialdif.com