Kevlar gloves offer exceptional cut resistance and heat protection, making them ideal for handling sharp objects and high-temperature environments in pet care. Dyneema gloves provide superior tensile strength and lightweight comfort, offering enhanced dexterity and prolonged wear during grooming or training sessions. Choosing between Kevlar and Dyneema gloves depends on whether durability against cuts or flexibility and comfort is the priority for pet-related tasks.

Table of Comparison

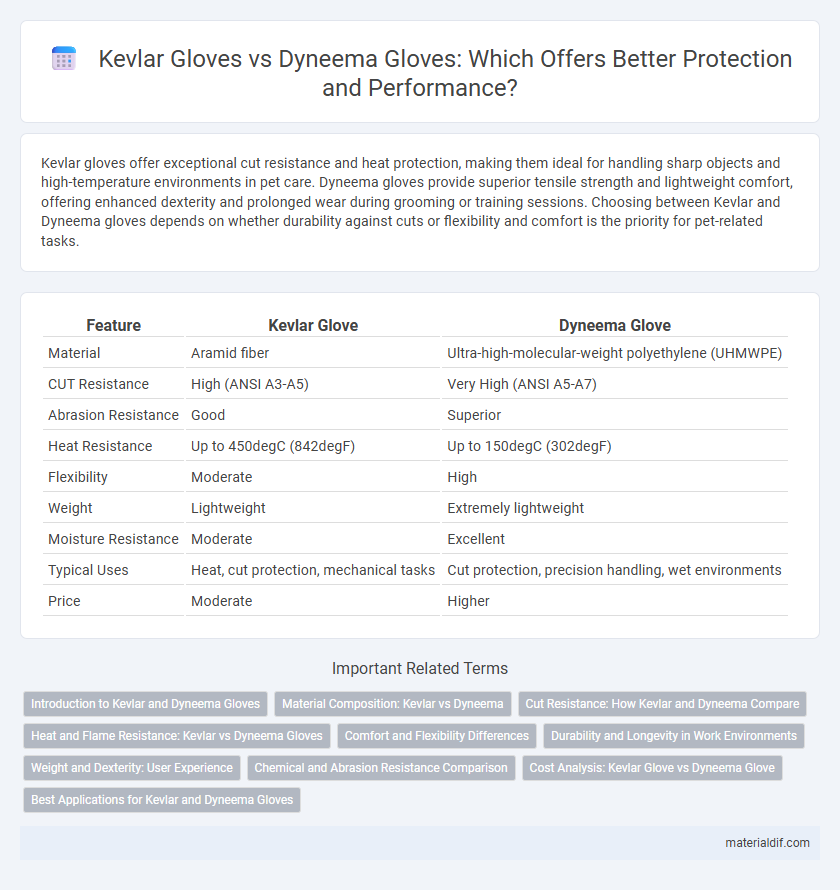

| Feature | Kevlar Glove | Dyneema Glove |

|---|---|---|

| Material | Aramid fiber | Ultra-high-molecular-weight polyethylene (UHMWPE) |

| CUT Resistance | High (ANSI A3-A5) | Very High (ANSI A5-A7) |

| Abrasion Resistance | Good | Superior |

| Heat Resistance | Up to 450degC (842degF) | Up to 150degC (302degF) |

| Flexibility | Moderate | High |

| Weight | Lightweight | Extremely lightweight |

| Moisture Resistance | Moderate | Excellent |

| Typical Uses | Heat, cut protection, mechanical tasks | Cut protection, precision handling, wet environments |

| Price | Moderate | Higher |

Introduction to Kevlar and Dyneema Gloves

Kevlar gloves offer exceptional cut resistance and heat protection due to their aramid fiber composition, making them ideal for industrial and construction applications. Dyneema gloves, made from ultra-high-molecular-weight polyethylene fibers, provide superior lightweight strength and enhanced dexterity while maintaining excellent cut resistance. Both gloves deliver high-performance hand protection, with Kevlar excelling in heat resistance and Dyneema focusing on lightweight durability.

Material Composition: Kevlar vs Dyneema

Kevlar gloves are made from aramid fibers known for high tensile strength, thermal resistance, and excellent cut protection, making them ideal for heat-intensive and sharp object handling environments. Dyneema gloves utilize ultra-high-molecular-weight polyethylene (UHMWPE) fibers, which provide superior cut resistance, lightweight comfort, and enhanced abrasion resistance. The difference in material composition results in Kevlar gloves excelling in heat resistance, while Dyneema gloves offer greater durability and flexibility for prolonged use.

Cut Resistance: How Kevlar and Dyneema Compare

Kevlar gloves offer exceptional cut resistance due to their aramid fiber construction, providing superior protection against sharp objects and industrial hazards. Dyneema gloves, made from ultra-high-molecular-weight polyethylene (UHMWPE), deliver high cut resistance with enhanced comfort and flexibility, often outperforming Kevlar in certain abrasion tests. When comparing cut resistance, Dyneema tends to excel in lightweight applications, while Kevlar remains highly effective in settings requiring thermal and high-impact resistance.

Heat and Flame Resistance: Kevlar vs Dyneema Gloves

Kevlar gloves exhibit superior heat and flame resistance due to their aramid fiber composition, maintaining structural integrity at temperatures up to 450degC (842degF), whereas Dyneema gloves, made from ultra-high-molecular-weight polyethylene, begin to melt around 150degC (302degF), compromising their protective capabilities. The inherent thermal stability of Kevlar fibers makes them ideal for applications involving direct flame exposure or high-heat environments. In contrast, Dyneema gloves excel in cut resistance and tensile strength but require additional treatment or layering to achieve comparable heat resistance.

Comfort and Flexibility Differences

Kevlar gloves offer moderate comfort with good heat resistance but tend to be stiffer due to their woven aramid fibers, limiting flexibility during extended use. Dyneema gloves provide superior comfort and flexibility, benefiting from ultra-high-molecular-weight polyethylene fibers that are lightweight and have exceptional dexterity. Users requiring prolonged wear and intricate hand movements generally prefer Dyneema gloves for their enhanced ergonomic performance.

Durability and Longevity in Work Environments

Kevlar gloves offer exceptional cut resistance and maintain their protective qualities under prolonged exposure to heat and abrasion, making them highly durable for heavy-duty industrial tasks. Dyneema gloves provide superior tensile strength and resistance to wear and tear, ensuring extended longevity in environments with frequent sharp or abrasive contact. Both materials excel in durability, but Kevlar's heat resistance and Dyneema's lightweight toughness make them ideal for different specialized work conditions.

Weight and Dexterity: User Experience

Kevlar gloves offer a balance of lightweight protection and moderate dexterity, making them suitable for tasks that require both safety and fine motor skills. Dyneema gloves are generally lighter than Kevlar and provide superior dexterity, enhancing user comfort and precision in detailed work. The reduced weight and increased flexibility of Dyneema gloves contribute to less hand fatigue during extended use compared to Kevlar gloves.

Chemical and Abrasion Resistance Comparison

Kevlar gloves exhibit superior chemical resistance against oils, solvents, and acids, maintaining integrity where Dyneema gloves may degrade more quickly. Dyneema gloves outperform in abrasion resistance, providing enhanced durability against mechanical wear and tear. Both materials offer distinct protective advantages, with Kevlar suited for chemical-intensive environments and Dyneema optimized for high-abrasion tasks.

Cost Analysis: Kevlar Glove vs Dyneema Glove

Kevlar gloves typically cost more upfront than Dyneema gloves due to their higher raw material and manufacturing expenses, but offer superior heat resistance and cut protection, which can reduce overall replacement frequency. Dyneema gloves are generally more affordable and provide excellent cut resistance and lightweight comfort, making them cost-effective for tasks requiring dexterity without extreme heat exposure. Evaluating total cost of ownership involves considering durability, protective performance, and specific workplace hazards to determine the best economic choice.

Best Applications for Kevlar and Dyneema Gloves

Kevlar gloves excel in environments requiring high heat resistance and cut protection, making them ideal for metal fabrication, glass handling, and automotive assembly. Dyneema gloves offer superior lightweight cut resistance and dexterity, suited for precision tasks in electronics, food processing, and assembly lines. Selecting the right glove depends on balancing protection needs with comfort and task-specific demands.

Kevlar glove vs Dyneema glove Infographic

materialdif.com

materialdif.com