Kevlar composite offers superior impact resistance and tensile strength compared to fiberglass composite, making it ideal for pet gear that requires enhanced durability and safety. Its lightweight nature ensures comfort for pets without compromising protection. Unlike fiberglass, Kevlar resists fraying and cracking, providing long-lasting performance in high-stress environments.

Table of Comparison

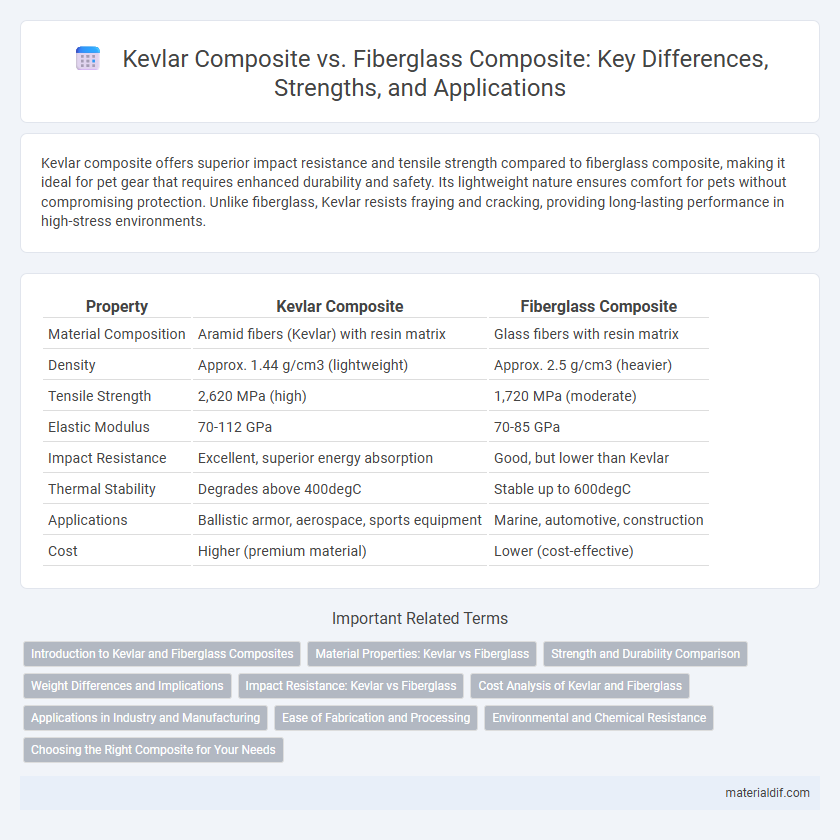

| Property | Kevlar Composite | Fiberglass Composite |

|---|---|---|

| Material Composition | Aramid fibers (Kevlar) with resin matrix | Glass fibers with resin matrix |

| Density | Approx. 1.44 g/cm3 (lightweight) | Approx. 2.5 g/cm3 (heavier) |

| Tensile Strength | 2,620 MPa (high) | 1,720 MPa (moderate) |

| Elastic Modulus | 70-112 GPa | 70-85 GPa |

| Impact Resistance | Excellent, superior energy absorption | Good, but lower than Kevlar |

| Thermal Stability | Degrades above 400degC | Stable up to 600degC |

| Applications | Ballistic armor, aerospace, sports equipment | Marine, automotive, construction |

| Cost | Higher (premium material) | Lower (cost-effective) |

Introduction to Kevlar and Fiberglass Composites

Kevlar composites consist of high-strength aramid fibers embedded in a resin matrix, offering exceptional impact resistance and tensile strength, making them ideal for ballistic and aerospace applications. Fiberglass composites comprise fine glass fibers woven into a matrix, providing excellent corrosion resistance and cost efficiency for automotive and construction uses. Both materials serve distinct performance roles, with Kevlar prioritized for high-performance protection and Fiberglass favored for versatility and affordability.

Material Properties: Kevlar vs Fiberglass

Kevlar composite exhibits superior tensile strength and impact resistance compared to fiberglass composite, making it ideal for high-performance applications requiring durability and lightweight characteristics. Kevlar's low density and excellent energy absorption significantly outperform fiberglass, which is heavier and less effective in withstanding repetitive stress or impact. While fiberglass offers good compressive strength and cost efficiency, Kevlar's enhanced toughness and flexibility provide greater reliability in demanding environments.

Strength and Durability Comparison

Kevlar composites exhibit superior tensile strength and impact resistance compared to fiberglass composites, making them ideal for high-performance applications requiring enhanced durability. Kevlar's molecular structure provides exceptional resistance to fatigue, abrasion, and cutting, significantly outperforming fiberglass in maintaining structural integrity under stress. While fiberglass composites offer good strength and cost-effectiveness, Kevlar composites deliver unmatched durability for critical safety and military uses.

Weight Differences and Implications

Kevlar composites exhibit a significantly lower density, approximately 1.44 g/cm3, compared to fiberglass composites, which have a density around 2.54 g/cm3, resulting in lighter overall structures. This weight difference directly improves fuel efficiency and handling in aerospace and automotive applications by reducing the load without compromising strength. The lower weight of Kevlar composites also enhances impact resistance and energy absorption, making them preferable in protective gear and high-performance components.

Impact Resistance: Kevlar vs Fiberglass

Kevlar composites exhibit superior impact resistance compared to fiberglass composites due to Kevlar's high tensile strength and energy absorption capabilities, which allow it to withstand sudden shocks and impacts without cracking. Fiberglass composites, while strong and cost-effective, tend to be more brittle and are prone to cracking or shattering under high-impact forces. The enhanced toughness of Kevlar composites makes them ideal for applications requiring extensive impact protection, such as ballistic armor and high-performance sporting equipment.

Cost Analysis of Kevlar and Fiberglass

Kevlar composites typically present higher material costs than fiberglass composites due to the complex manufacturing process and raw material expenses. Fiberglass offers a more cost-effective solution with lower material and fabrication costs, making it preferred for budget-sensitive applications. Despite the higher initial cost, Kevlar provides superior strength-to-weight ratio and impact resistance, which can justify its investment in high-performance uses.

Applications in Industry and Manufacturing

Kevlar composite offers superior impact resistance and higher tensile strength compared to fiberglass composite, making it ideal for aerospace, automotive, and ballistic armor applications where lightweight durability is critical. Fiberglass composites are favored in marine, construction, and wind energy industries due to their cost-effectiveness and resistance to corrosion and environmental degradation. Manufacturing processes for Kevlar composites often require specialized handling to maintain fiber integrity, whereas fiberglass composites benefit from more versatile and established fabrication techniques.

Ease of Fabrication and Processing

Kevlar composites offer greater ease of fabrication due to their lightweight and flexible fiber structure, which allows for better conformity to complex shapes compared to fiberglass composites. The processing of Kevlar involves lower curing temperatures and reduced risk of fiber damage during handling, enhancing manufacturing efficiency and reducing defects. Fiberglass composites, while generally more rigid, require higher curing temperatures and more careful handling to avoid fiber breakage, making them less adaptable for intricate designs.

Environmental and Chemical Resistance

Kevlar composites exhibit superior chemical resistance compared to fiberglass composites, with exceptional durability against solvents, acids, and alkalis. Kevlar's molecular structure provides outstanding resistance to environmental factors such as UV radiation and moisture, reducing degradation over time. Fiberglass composites, while resistant to many chemicals, tend to absorb water and degrade faster under prolonged UV exposure, limiting their lifespan in harsh environmental conditions.

Choosing the Right Composite for Your Needs

Kevlar composite offers superior tensile strength and impact resistance compared to fiberglass composite, making it ideal for applications requiring high durability and lightweight performance. Fiberglass composites provide better cost-efficiency and resistance to environmental factors such as moisture and UV exposure, suitable for budget-conscious projects with moderate strength needs. Selecting between Kevlar and fiberglass composites hinges on balancing factors like strength requirements, budget constraints, and environmental exposure.

Kevlar composite vs Fiberglass composite Infographic

materialdif.com

materialdif.com