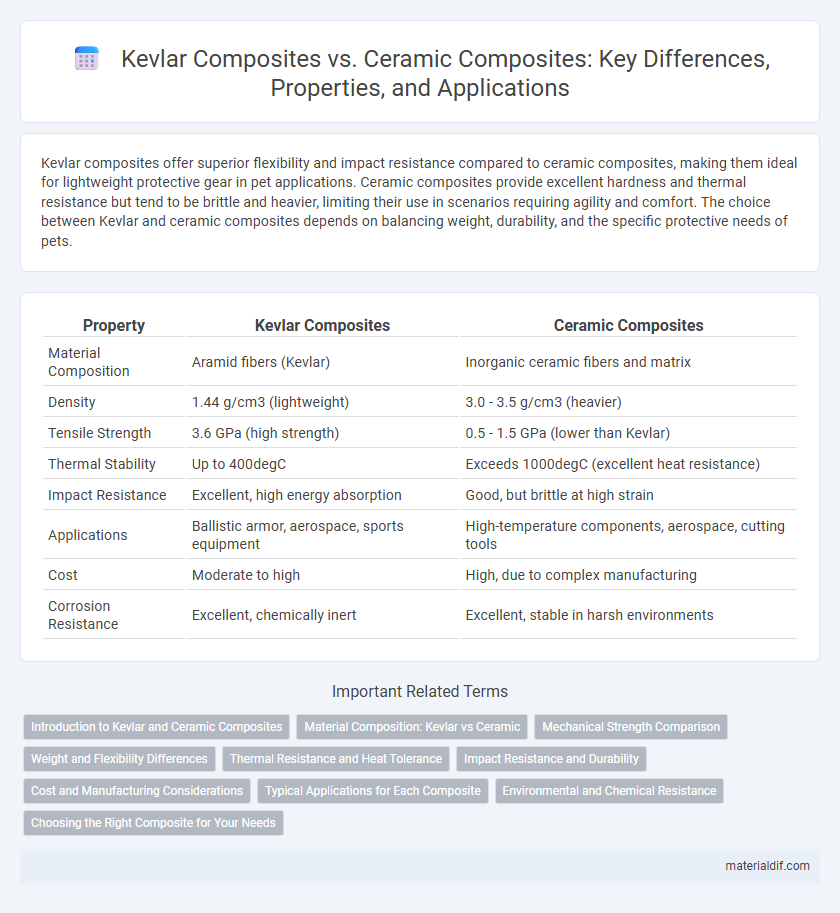

Kevlar composites offer superior flexibility and impact resistance compared to ceramic composites, making them ideal for lightweight protective gear in pet applications. Ceramic composites provide excellent hardness and thermal resistance but tend to be brittle and heavier, limiting their use in scenarios requiring agility and comfort. The choice between Kevlar and ceramic composites depends on balancing weight, durability, and the specific protective needs of pets.

Table of Comparison

| Property | Kevlar Composites | Ceramic Composites |

|---|---|---|

| Material Composition | Aramid fibers (Kevlar) | Inorganic ceramic fibers and matrix |

| Density | 1.44 g/cm3 (lightweight) | 3.0 - 3.5 g/cm3 (heavier) |

| Tensile Strength | 3.6 GPa (high strength) | 0.5 - 1.5 GPa (lower than Kevlar) |

| Thermal Stability | Up to 400degC | Exceeds 1000degC (excellent heat resistance) |

| Impact Resistance | Excellent, high energy absorption | Good, but brittle at high strain |

| Applications | Ballistic armor, aerospace, sports equipment | High-temperature components, aerospace, cutting tools |

| Cost | Moderate to high | High, due to complex manufacturing |

| Corrosion Resistance | Excellent, chemically inert | Excellent, stable in harsh environments |

Introduction to Kevlar and Ceramic Composites

Kevlar composites consist of high-strength synthetic fibers woven into a polymer matrix, offering exceptional tensile strength and impact resistance ideal for ballistic protection and lightweight structural applications. Ceramic composites combine ceramic fibers or particles within a matrix, providing superior hardness, heat resistance, and durability essential for armor plating and aerospace components. Both materials are engineered to optimize performance in extreme conditions, with Kevlar excelling in flexibility and ceramics in thermal and wear resistance.

Material Composition: Kevlar vs Ceramic

Kevlar composites consist primarily of aramid fibers known for their high tensile strength-to-weight ratio and excellent impact resistance, making them ideal for ballistic and lightweight applications. Ceramic composites utilize inorganic, non-metallic materials like alumina or silicon carbide, offering superior hardness, thermal stability, and resistance to wear and corrosion. The fundamental difference in material composition results in Kevlar composites providing flexibility and energy absorption, whereas ceramic composites deliver rigidity and enhanced protection against high-velocity impacts.

Mechanical Strength Comparison

Kevlar composites exhibit exceptional tensile strength and flexibility, making them highly effective in impact resistance and energy absorption applications. Ceramic composites offer superior compressive strength and hardness, providing excellent resistance to wear and high temperature environments. The mechanical strength comparison highlights Kevlar's advantage in toughness and lightweight properties, while ceramic composites excel in rigidity and thermal stability.

Weight and Flexibility Differences

Kevlar composites are significantly lighter than ceramic composites, providing enhanced weight savings crucial for applications such as ballistic armor and aerospace components. The inherent flexibility of Kevlar fibers allows Kevlar composites to absorb and dissipate energy effectively, making them less brittle compared to rigid ceramic composites. Ceramic composites, while offering superior hardness and thermal resistance, tend to be heavier and more brittle, limiting their use in dynamic environments where flexibility and reduced weight are essential.

Thermal Resistance and Heat Tolerance

Kevlar composites exhibit excellent thermal resistance withstanding temperatures up to 400degC without significant degradation, making them ideal for applications requiring heat tolerance and impact resistance. Ceramic composites surpass Kevlar in heat tolerance, maintaining structural integrity at extreme temperatures exceeding 1000degC, which is essential in high-temperature environments such as aerospace and industrial furnaces. While Kevlar composites provide flexible and lightweight thermal protection, ceramic composites deliver superior heat resistance but with increased brittleness and weight.

Impact Resistance and Durability

Kevlar composites exhibit superior impact resistance due to their high tensile strength and excellent energy absorption capabilities, making them ideal for applications requiring flexibility and toughness. Ceramic composites excel in durability and heat resistance, offering exceptional hardness and wear resistance but are more brittle under impact stress. The choice between Kevlar and ceramic composites depends on the specific demands of impact resistance versus long-term structural durability in high-stress environments.

Cost and Manufacturing Considerations

Kevlar composites offer lower material and manufacturing costs compared to ceramic composites, making them more suitable for applications requiring economical production. The fabrication of Kevlar composites involves simpler molding techniques and shorter curing times, reducing labor and energy expenses. Ceramic composites, while offering superior heat resistance and hardness, necessitate complex high-temperature processing and specialized equipment, significantly increasing overall manufacturing costs.

Typical Applications for Each Composite

Kevlar composites are extensively used in ballistic protection gear, such as body armor and helmets, due to their lightweight and high impact resistance. Ceramic composites find typical applications in aerospace and military armor systems where extreme hardness and thermal stability are critical. Both materials serve crucial roles in defense and safety industries, with Kevlar favored for flexibility and ceramic composites for superior durability under high-stress conditions.

Environmental and Chemical Resistance

Kevlar composites exhibit superior environmental and chemical resistance compared to ceramic composites due to their high tensile strength and resistance to moisture, acids, and alkalis. Kevlar's polymeric structure enables it to maintain integrity under harsh chemical exposures, whereas ceramic composites are prone to degradation and cracking when exposed to certain chemicals and thermal cycling. The enhanced durability of Kevlar composites makes them ideal for applications requiring long-term resistance to corrosive environments and fluctuating environmental conditions.

Choosing the Right Composite for Your Needs

Kevlar composites offer superior impact resistance and flexibility, making them ideal for applications requiring lightweight durability such as body armor and aerospace components. Ceramic composites excel in high-temperature environments and provide exceptional hardness and wear resistance, suitable for ballistic protection and engine parts. Selecting the right composite depends on balancing factors like weight, thermal stability, and impact tolerance to match the specific operational demands.

Kevlar Composites vs Ceramic Composites Infographic

materialdif.com

materialdif.com