Kevlar offers exceptional heat resistance and tensile strength, making it ideal for high-impact pet gear, while Dyneema provides superior lightweight durability and excellent cut resistance for active pets. Both fibers enhance pet safety by protecting against bites and abrasions, but Dyneema's lighter feel often improves comfort and mobility. Choosing between Kevlar and Dyneema depends on specific needs for toughness versus weight in pet accessories.

Table of Comparison

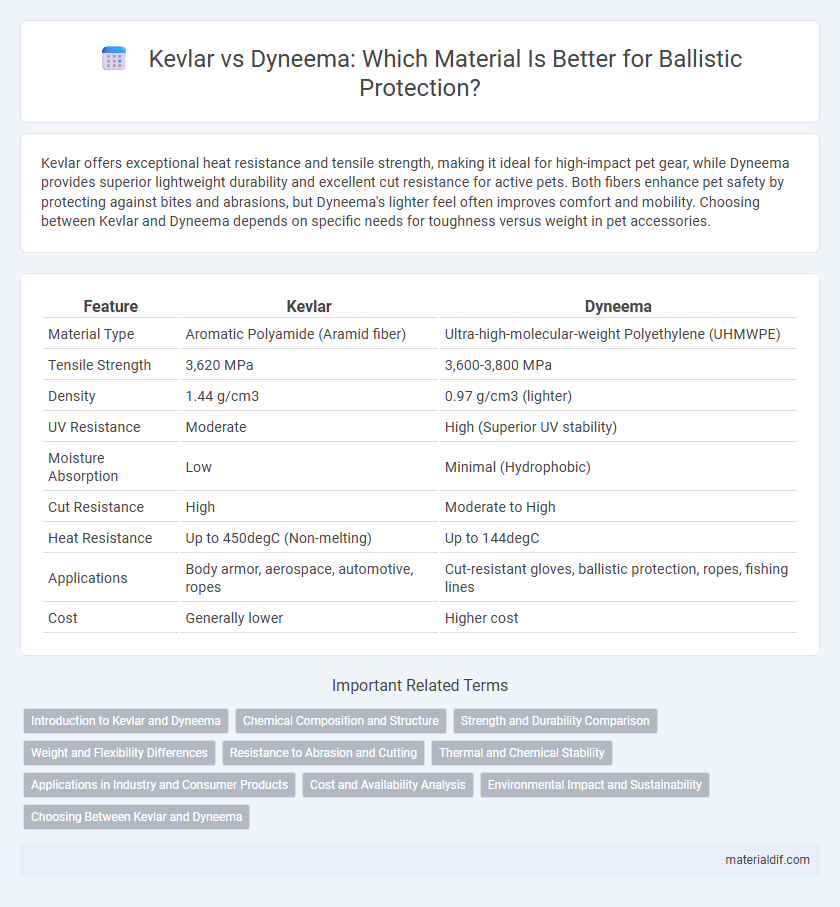

| Feature | Kevlar | Dyneema |

|---|---|---|

| Material Type | Aromatic Polyamide (Aramid fiber) | Ultra-high-molecular-weight Polyethylene (UHMWPE) |

| Tensile Strength | 3,620 MPa | 3,600-3,800 MPa |

| Density | 1.44 g/cm3 | 0.97 g/cm3 (lighter) |

| UV Resistance | Moderate | High (Superior UV stability) |

| Moisture Absorption | Low | Minimal (Hydrophobic) |

| Cut Resistance | High | Moderate to High |

| Heat Resistance | Up to 450degC (Non-melting) | Up to 144degC |

| Applications | Body armor, aerospace, automotive, ropes | Cut-resistant gloves, ballistic protection, ropes, fishing lines |

| Cost | Generally lower | Higher cost |

Introduction to Kevlar and Dyneema

Kevlar is a synthetic aramid fiber renowned for its high tensile strength and thermal stability, making it ideal for applications like body armor and aerospace components. Dyneema, an ultra-high-molecular-weight polyethylene fiber, offers exceptional strength-to-weight ratio and superior cut resistance, widely used in ballistic protection and marine equipment. Both fibers provide lightweight, durable solutions but differ in chemical composition and specific performance characteristics tailored to various industrial needs.

Chemical Composition and Structure

Kevlar is an aramid fiber composed of poly-paraphenylene terephthalamide, characterized by its rigid, crystalline structure formed through strong hydrogen bonding between polymer chains. Dyneema, made from ultra-high-molecular-weight polyethylene (UHMWPE), features long, linear chains of polyethylene with high molecular weight and low crystallinity, providing exceptional tensile strength and flexibility. The aromatic amide bonds in Kevlar contribute to its heat resistance, while Dyneema's chemical composition allows for lower density and greater impact absorption.

Strength and Durability Comparison

Kevlar exhibits exceptional tensile strength and high resistance to impact, making it ideal for applications requiring durability under extreme conditions. Dyneema, while boasting higher tensile strength than Kevlar by weight, offers superior abrasion resistance and flexibility, enhancing its durability in dynamic environments. Both fibers excel in protective gear, but Kevlar's thermal stability provides an advantage in high-heat scenarios, whereas Dyneema's lightweight nature favors mobility without compromising strength.

Weight and Flexibility Differences

Kevlar fibers are denser and less flexible compared to Dyneema, resulting in higher weight but increased strength in ballistic protection. Dyneema, made from ultra-high-molecular-weight polyethylene (UHMWPE), offers superior flexibility and is significantly lighter, enhancing mobility for applications like body armor and helmets. The weight difference can be as much as 40%, with Dyneema providing a lighter alternative without compromising tensile strength.

Resistance to Abrasion and Cutting

Kevlar offers exceptional resistance to abrasion and cutting due to its tightly woven aramid fibers, making it highly effective for protective gear and industrial applications. Dyneema, known for its ultra-high molecular weight polyethylene composition, provides superior cut resistance with a smoother surface that reduces fiber damage under friction. Both materials deliver outstanding durability, but Kevlar excels in sustained abrasion resistance while Dyneema outperforms in sharp cut protection.

Thermal and Chemical Stability

Kevlar exhibits superior thermal stability with a continuous use temperature of approximately 450degC, while Dyneema melts at a much lower temperature around 144degC, limiting its high-heat applications. Chemically, Kevlar resists solvents, acids, and bases better than Dyneema, which tends to degrade under prolonged exposure to UV light and certain chemicals. This makes Kevlar the preferred choice for environments requiring high thermal endurance and chemical resistance.

Applications in Industry and Consumer Products

Kevlar offers superior heat resistance and tensile strength, making it ideal for ballistic armor, automotive components, and aerospace parts, whereas Dyneema excels in lightweight, high-strength applications like maritime ropes, fishing lines, and cut-resistant gloves. Kevlar's aromatic polyamide structure provides durability and impact protection favored in military and industrial safety gear, while Dyneema's ultra-high-molecular-weight polyethylene composition delivers exceptional abrasion resistance and flexibility for consumer sporting goods and outdoor equipment. Both fibers dominate protective textiles, but Kevlar leads in heat-sensitive environments and Dyneema prevails where lightweight performance is critical.

Cost and Availability Analysis

Kevlar typically costs more per kilogram than Dyneema, driven by its complex manufacturing process and strong brand presence in ballistic protection markets. Dyneema is more widely available due to its production scalability and application in diverse industries such as marine, sports, and industrial safety, contributing to lower market prices. Supply chain robustness for Dyneema often results in shorter lead times compared to Kevlar, making it a cost-effective option for bulk procurement.

Environmental Impact and Sustainability

Kevlar is a synthetic aramid fiber known for its high strength and durability, but its production involves energy-intensive processes and the use of hazardous chemicals, contributing to a larger environmental footprint. Dyneema, made from ultra-high-molecular-weight polyethylene (UHMWPE), offers a more sustainable profile due to lower energy consumption in manufacturing and its potential for recycling. Both materials have environmental challenges, but Dyneema's lighter weight also reduces transportation emissions, enhancing overall sustainability compared to Kevlar.

Choosing Between Kevlar and Dyneema

Kevlar offers exceptional heat resistance and tensile strength, making it ideal for applications requiring high durability under extreme temperatures, while Dyneema is renowned for its ultra-high strength-to-weight ratio and superior cut resistance. Selecting between Kevlar and Dyneema depends largely on specific use cases such as ballistic protection, rope manufacturing, or protective gear, where factors like flexibility, UV resistance, and moisture sensitivity play critical roles. Evaluating performance metrics like tensile strength (Kevlar: ~3,620 MPa, Dyneema: ~3,600 MPa) and density (Kevlar: 1.44 g/cm3, Dyneema: 0.97 g/cm3) helps in making an informed decision tailored to the demands of the application.

Kevlar vs Dyneema Infographic

materialdif.com

materialdif.com