Weft-inserted Kevlar offers enhanced flexibility and improved tear resistance compared to plain-woven Kevlar, making it ideal for pet products requiring durability and comfort. The weaving technique integrates Kevlar threads horizontally, providing better strength distribution and impact absorption. In contrast, plain-woven Kevlar features a simpler over-under pattern that, while strong, may lack the adaptability needed for active pets.

Table of Comparison

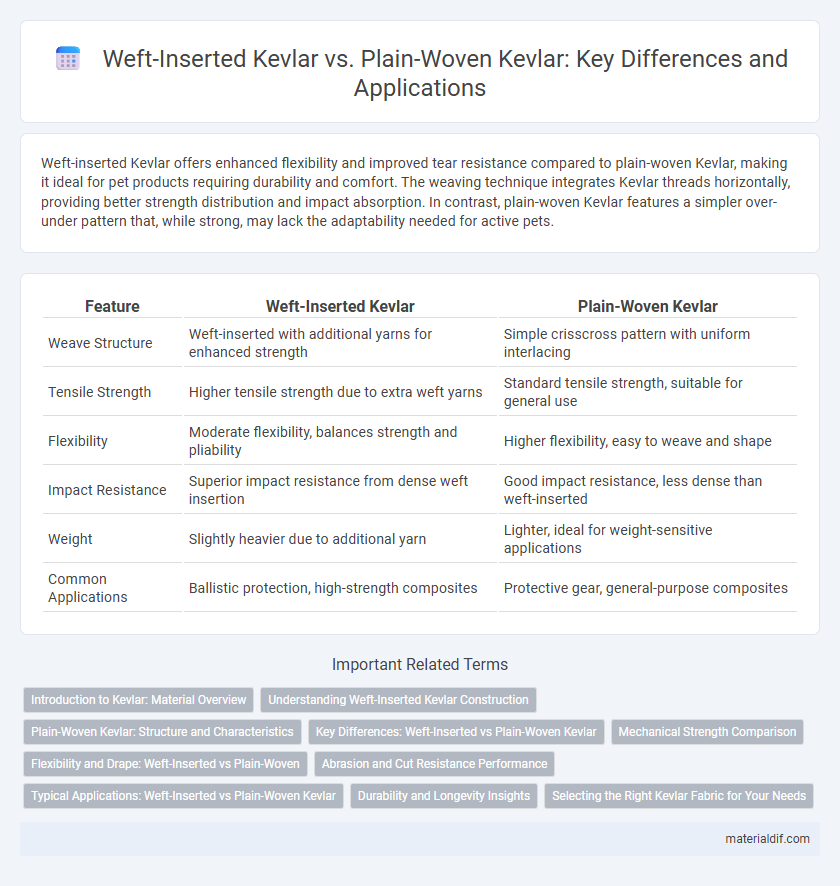

| Feature | Weft-Inserted Kevlar | Plain-Woven Kevlar |

|---|---|---|

| Weave Structure | Weft-inserted with additional yarns for enhanced strength | Simple crisscross pattern with uniform interlacing |

| Tensile Strength | Higher tensile strength due to extra weft yarns | Standard tensile strength, suitable for general use |

| Flexibility | Moderate flexibility, balances strength and pliability | Higher flexibility, easy to weave and shape |

| Impact Resistance | Superior impact resistance from dense weft insertion | Good impact resistance, less dense than weft-inserted |

| Weight | Slightly heavier due to additional yarn | Lighter, ideal for weight-sensitive applications |

| Common Applications | Ballistic protection, high-strength composites | Protective gear, general-purpose composites |

Introduction to Kevlar: Material Overview

Kevlar, a high-strength aramid fiber developed by DuPont, is widely used in ballistic and protective applications due to its exceptional tensile strength-to-weight ratio and thermal stability. Weft-inserted Kevlar fabric incorporates extra weft yarns to enhance impact resistance and dimensional stability, making it suitable for advanced composite structures. Plain-woven Kevlar features a uniform interlacing of warp and weft fibers, offering balanced mechanical properties and increased durability for standard protective gear and body armor.

Understanding Weft-Inserted Kevlar Construction

Weft-inserted Kevlar construction features additional weft yarns integrated into the primary warp yarns, enhancing fabric strength and flexibility compared to plain-woven Kevlar which relies solely on interlaced warp and weft yarns in a uniform pattern. This method improves impact resistance and durability, making weft-inserted Kevlar ideal for ballistic protection and high-performance composite materials. The specialized weave structure of weft-inserted Kevlar optimizes load distribution, reducing fabric deformation under stress.

Plain-Woven Kevlar: Structure and Characteristics

Plain-woven Kevlar features a simple over-under weave pattern that enhances uniform strength and consistent load distribution across the fabric. This structure provides excellent dimensional stability, resistance to abrasion, and high tensile strength, making it ideal for protective gear and ballistic applications. The tight weave also contributes to superior cut resistance and durability compared to more complex weaves like weft-inserted Kevlar.

Key Differences: Weft-Inserted vs Plain-Woven Kevlar

Weft-inserted Kevlar features transverse yarns woven into a unidirectional fabric to improve transverse strength and dimensional stability, while plain-woven Kevlar interlaces warp and weft yarns uniformly for balanced strength and flexibility. The weft insertion technique enhances impact resistance and shear strength, making the fabric ideal for ballistic applications. In contrast, plain-woven Kevlar offers greater drapeability and abrasion resistance, suited for flexible protective gear and composite reinforcements.

Mechanical Strength Comparison

Weft-inserted Kevlar exhibits enhanced mechanical strength compared to plain-woven Kevlar due to the additional weft fibers that improve load distribution and resistance to tensile stress. The insertion of weft yarns increases impact absorption and shear resistance, making it more suitable for high-performance applications such as ballistic armor and aerospace components. Plain-woven Kevlar, while offering good strength and flexibility, tends to have lower tensile strength and less efficient stress transfer under mechanical loading.

Flexibility and Drape: Weft-Inserted vs Plain-Woven

Weft-inserted Kevlar offers enhanced flexibility and superior drape compared to plain-woven Kevlar, making it ideal for applications requiring conformability and ease of movement. The insertion of weft yarns reduces fabric stiffness, allowing the material to better contour complex shapes without compromising strength. Plain-woven Kevlar, while providing excellent tensile strength and abrasion resistance, tends to be stiffer and less adaptable in flexible or curved applications.

Abrasion and Cut Resistance Performance

Weft-inserted Kevlar exhibits superior abrasion and cut resistance compared to plain-woven Kevlar due to its reinforced fiber orientation, which enhances durability under friction and sharp impacts. The interlaced weft yarns in this structure provide increased resistance to surface wear and tearing, making it ideal for protective gear and industrial applications. Plain-woven Kevlar, while strong, offers less resistance to repetitive abrasion and cutting forces due to its simpler, uniform weave.

Typical Applications: Weft-Inserted vs Plain-Woven Kevlar

Weft-inserted Kevlar is commonly used in ballistic-resistant body armor and helmets due to its enhanced impact resistance and flexibility, allowing for improved comfort and protection. Plain-woven Kevlar finds typical applications in aerospace components, ropes, and cables where uniform strength and stiffness are critical. The weft-inserted variant offers superior abrasion resistance compared to plain-woven Kevlar, making it suitable for dynamic, high-stress environments.

Durability and Longevity Insights

Weft-inserted Kevlar exhibits enhanced durability due to the additional weft yarns that increase resistance to abrasion and impact compared to plain-woven Kevlar. This weaving technique improves longevity by distributing stress more evenly, reducing fiber breakage over time. Studies show that weft-inserted Kevlar maintains structural integrity longer in high-stress applications, making it ideal for protective gear and industrial uses.

Selecting the Right Kevlar Fabric for Your Needs

Weft-inserted Kevlar features enhanced rigidity and impact resistance due to additional weft yarns, making it ideal for applications requiring superior structural strength and durability. Plain-woven Kevlar offers balanced flexibility and breathability, suitable for lightweight protective gear and apparel where comfort and mobility are prioritized. Selecting the right Kevlar fabric depends on evaluating the specific demands of your project, such as whether more stiffness or flexibility is crucial for optimal performance and safety.

Weft-inserted Kevlar vs Plain-woven Kevlar Infographic

materialdif.com

materialdif.com