Ballistic nylon offers excellent abrasion resistance and durability, making it a popular choice for pet gear that requires toughness and longevity. Kevlar surpasses ballistic nylon in strength and cut resistance, providing superior protection for pets in hazardous environments. While ballistic nylon is effective for everyday use, Kevlar is the preferred material when enhanced impact and puncture resistance are critical.

Table of Comparison

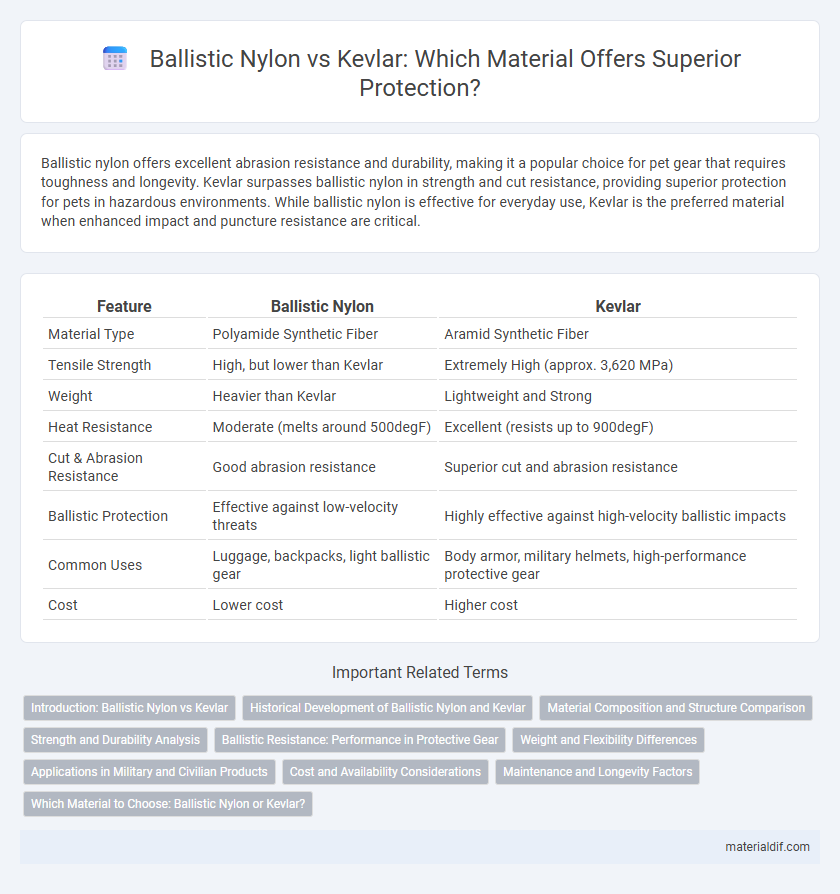

| Feature | Ballistic Nylon | Kevlar |

|---|---|---|

| Material Type | Polyamide Synthetic Fiber | Aramid Synthetic Fiber |

| Tensile Strength | High, but lower than Kevlar | Extremely High (approx. 3,620 MPa) |

| Weight | Heavier than Kevlar | Lightweight and Strong |

| Heat Resistance | Moderate (melts around 500degF) | Excellent (resists up to 900degF) |

| Cut & Abrasion Resistance | Good abrasion resistance | Superior cut and abrasion resistance |

| Ballistic Protection | Effective against low-velocity threats | Highly effective against high-velocity ballistic impacts |

| Common Uses | Luggage, backpacks, light ballistic gear | Body armor, military helmets, high-performance protective gear |

| Cost | Lower cost | Higher cost |

Introduction: Ballistic Nylon vs Kevlar

Ballistic nylon, developed during World War II for military use, is a tough, synthetic fabric known for its durability and abrasion resistance. Kevlar, invented by DuPont in the 1960s, is an aramid fiber celebrated for its exceptional tensile strength and ballistic protection capabilities. While ballistic nylon offers solid resistance to wear and tear, Kevlar provides superior impact and penetration resistance, making it the material of choice for bulletproof vests and high-performance protective gear.

Historical Development of Ballistic Nylon and Kevlar

Ballistic nylon was originally developed during World War II by DuPont as a strong fabric to protect airmen from shrapnel and debris, characterized by its thick weave and resistance to abrasion. Kevlar, invented by Stephanie Kwolek at DuPont in 1965, revolutionized ballistic protection with its ultra-high tensile strength and lightweight composition, quickly replacing ballistic nylon in many applications. The transition from ballistic nylon to Kevlar marked a significant advancement in personal armor, offering enhanced protection against projectiles while reducing weight for better mobility.

Material Composition and Structure Comparison

Ballistic Nylon is a thick, tough synthetic fabric made from nylon fibers woven in a tight basketweave pattern, providing excellent abrasion resistance and durability. Kevlar, composed of para-aramid synthetic fibers, features a highly oriented molecular structure with strong hydrogen bonding, resulting in superior tensile strength and ballistic protection. The key difference lies in Kevlar's molecular alignment and fiber properties, which offer enhanced stab and bullet resistance compared to the more abrasion-focused Ballistic Nylon.

Strength and Durability Analysis

Kevlar exhibits significantly higher tensile strength compared to ballistic nylon, making it more resistant to penetration and abrasion in high-impact scenarios. While ballistic nylon offers considerable durability against wear and tear, Kevlar's exceptional polymer structure provides superior cut resistance and long-term resilience under extreme stress. This strength advantage makes Kevlar the preferred material for ballistic protection in military and law enforcement applications.

Ballistic Resistance: Performance in Protective Gear

Ballistic Nylon offers high abrasion resistance and durability, making it effective for lightweight protective gear, but it falls short in stopping high-velocity projectiles compared to Kevlar. Kevlar fibers provide superior ballistic resistance by effectively dispersing the energy of bullets and shrapnel, making it a preferred choice in bulletproof vests and helmets. The enhanced tensile strength and energy absorption capabilities of Kevlar result in significantly better protective performance against ballistic threats.

Weight and Flexibility Differences

Ballistic nylon is heavier and less flexible compared to Kevlar, making Kevlar a preferred choice for lightweight and highly flexible protective gear. Kevlar fibers provide superior impact resistance while maintaining a lower weight, enhancing mobility for users in tactical or combat scenarios. This balance of reduced weight and increased flexibility in Kevlar significantly improves comfort and effectiveness in ballistic protection applications.

Applications in Military and Civilian Products

Kevlar offers superior ballistic protection compared to ballistic nylon, making it the preferred material for military body armor and helmets due to its high tensile strength and lightweight properties. Ballistic nylon is commonly used in civilian products such as luggage, backpacks, and protective gear where abrasion resistance is prioritized over ballistic performance. The integration of Kevlar in military applications enhances survivability, while ballistic nylon serves well in everyday protective contexts, balancing durability and cost-effectiveness.

Cost and Availability Considerations

Ballistic nylon tends to be more affordable and widely available than Kevlar, making it a popular choice for budget-conscious applications such as backpacks and luggage. Kevlar, despite its higher cost, offers superior ballistic protection and durability, which justifies its use in military and law enforcement gear. The production of Kevlar involves complex processes that limit its availability and increase its price compared to the more common ballistic nylon.

Maintenance and Longevity Factors

Kevlar outperforms ballistic nylon in terms of maintenance and longevity due to its superior resistance to abrasion, heat, and chemical exposure, which extends the lifespan of protective gear. Ballistic nylon requires more frequent inspection and cleaning to prevent wear and tear, as its fibers are less resilient under harsh conditions. Kevlar's inherent durability reduces the need for frequent replacements, making it a cost-effective choice for long-term use in safety applications.

Which Material to Choose: Ballistic Nylon or Kevlar?

Kevlar offers superior ballistic protection due to its high tensile strength-to-weight ratio, making it ideal for bulletproof vests and armor. Ballistic nylon provides excellent abrasion resistance and durability but lacks the same level of ballistic resistance, making it suitable for protective gear and luggage rather than life-saving armor. Choosing between Ballistic nylon and Kevlar depends on the required balance of protection, weight, and flexibility for specific applications.

Ballistic Nylon vs Kevlar Infographic

materialdif.com

materialdif.com