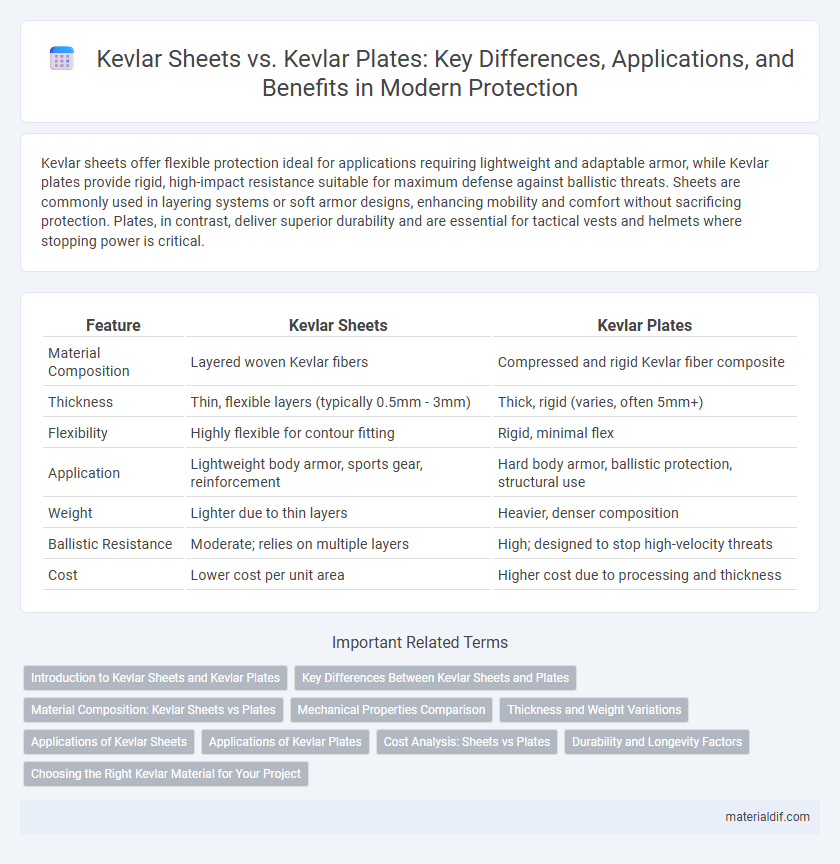

Kevlar sheets offer flexible protection ideal for applications requiring lightweight and adaptable armor, while Kevlar plates provide rigid, high-impact resistance suitable for maximum defense against ballistic threats. Sheets are commonly used in layering systems or soft armor designs, enhancing mobility and comfort without sacrificing protection. Plates, in contrast, deliver superior durability and are essential for tactical vests and helmets where stopping power is critical.

Table of Comparison

| Feature | Kevlar Sheets | Kevlar Plates |

|---|---|---|

| Material Composition | Layered woven Kevlar fibers | Compressed and rigid Kevlar fiber composite |

| Thickness | Thin, flexible layers (typically 0.5mm - 3mm) | Thick, rigid (varies, often 5mm+) |

| Flexibility | Highly flexible for contour fitting | Rigid, minimal flex |

| Application | Lightweight body armor, sports gear, reinforcement | Hard body armor, ballistic protection, structural use |

| Weight | Lighter due to thin layers | Heavier, denser composition |

| Ballistic Resistance | Moderate; relies on multiple layers | High; designed to stop high-velocity threats |

| Cost | Lower cost per unit area | Higher cost due to processing and thickness |

Introduction to Kevlar Sheets and Kevlar Plates

Kevlar sheets consist of flexible, woven layers of aramid fibers designed for applications requiring lightweight, cut-resistant material with some degree of flexibility. Kevlar plates are rigid, compressed or laminated versions of Kevlar used primarily for ballistic protection and impact resistance in armor systems. Both forms utilize Kevlar's high tensile strength and thermal stability, but sheets suit protective clothing and composites, while plates are essential in hard body armor and vehicle reinforcements.

Key Differences Between Kevlar Sheets and Plates

Kevlar sheets are flexible, thin layers primarily used for lightweight applications such as body armor and protective clothing, while Kevlar plates are rigid, thicker structures designed for heavy-duty ballistic protection in military and law enforcement gear. The key differences between Kevlar sheets and plates lie in their density, weight, and impact resistance, with plates offering superior multi-hit capability and increased stop power at the cost of reduced flexibility. Understanding these distinctions helps in selecting the appropriate Kevlar form for specific protective equipment based on mobility requirements and threat level.

Material Composition: Kevlar Sheets vs Plates

Kevlar sheets consist of woven aramid fibers bonded in flexible layers, offering excellent tensile strength and impact resistance while maintaining lightweight properties. Kevlar plates, by contrast, are composed of multiple compressed and resin-infused Kevlar fiber layers, resulting in a rigid, durable structure designed for high-stress ballistic protection. The difference in material composition between sheets and plates directly influences their applications, with sheets used for flexible armor solutions and plates for rigid, high-impact safeguarding.

Mechanical Properties Comparison

Kevlar sheets exhibit high tensile strength and superior flexibility, making them ideal for applications requiring lightweight, impact-resistant materials with good energy absorption. Kevlar plates offer enhanced rigidity and increased resistance to penetration, providing better structural support and durability under high-stress conditions. The mechanical properties of Kevlar plates typically include higher hardness and stiffness compared to sheets, which excel in tensile modulus and elongation before failure.

Thickness and Weight Variations

Kevlar sheets are typically thinner and more flexible than Kevlar plates, allowing for easier layering and customization in lightweight applications. Kevlar plates, on the other hand, offer increased thickness and rigidity, providing enhanced ballistic protection but with added weight. The choice between sheets and plates depends on the balance between desired thickness for impact resistance and the overall weight constraints of the protective gear.

Applications of Kevlar Sheets

Kevlar sheets are widely used in applications requiring flexibility and lightweight impact resistance, such as in ballistic vests, protective gloves, and composite reinforcements for automotive and aerospace components. Unlike Kevlar plates, which provide rigid protection for body armor and structural parts, Kevlar sheets offer enhanced versatility for layering and molding into complex shapes. Their excellent tensile strength and energy absorption make them ideal for use in flexible armor systems and protective sports gear.

Applications of Kevlar Plates

Kevlar plates are extensively used in ballistic protection equipment such as body armor, helmets, and vehicle armor due to their superior impact resistance and ability to dissipate energy effectively. These rigid plates provide enhanced protection against high-velocity projectiles and blunt force trauma compared to flexible Kevlar sheets. Their application in military and law enforcement gear ensures increased survivability and durability in hostile environments.

Cost Analysis: Sheets vs Plates

Kevlar sheets generally offer a more cost-effective solution than Kevlar plates due to lower manufacturing complexity and material usage, making them ideal for applications requiring flexibility and lightweight protection. Kevlar plates, being thicker and denser, involve higher production costs but provide superior ballistic resistance for critical defense applications. Analyzing cost per unit area reveals that Kevlar sheets maximize budget efficiency for larger surface coverage, while Kevlar plates justify their premium price through enhanced impact durability and longevity.

Durability and Longevity Factors

Kevlar sheets offer superior flexibility and ease of application, making them ideal for dynamic environments requiring impact resistance without compromising movement. Kevlar plates provide enhanced structural rigidity and higher resistance to penetration, ensuring long-term durability in high-stress protective gear and ballistic armor. The longevity of Kevlar products depends on factors such as environmental exposure, handling, and specific resin treatments used during manufacturing, with plates generally outperforming sheets in sustained protection scenarios.

Choosing the Right Kevlar Material for Your Project

Kevlar sheets offer flexibility and lightweight protection, making them ideal for applications requiring contouring and ease of fabrication, such as body armor linings and sports equipment. Kevlar plates provide enhanced ballistic resistance and rigidity, suitable for high-impact environments like military vehicles and protective gear inserts. Selecting the right Kevlar material depends on balancing factors like required durability, impact resistance, weight constraints, and the specific structural demands of your project.

Kevlar Sheets vs Kevlar Plates Infographic

materialdif.com

materialdif.com