Epoxy resin offers superior adhesion, chemical resistance, and mechanical strength compared to vinyl ester resin, making it ideal for high-performance Kevlar pet applications. Vinyl ester resin provides better flexibility and impact resistance but has slightly lower durability and fatigue resistance under extreme stress. Choosing between epoxy and vinyl ester depends on the balance required between strength and toughness for specific Kevlar pet product needs.

Table of Comparison

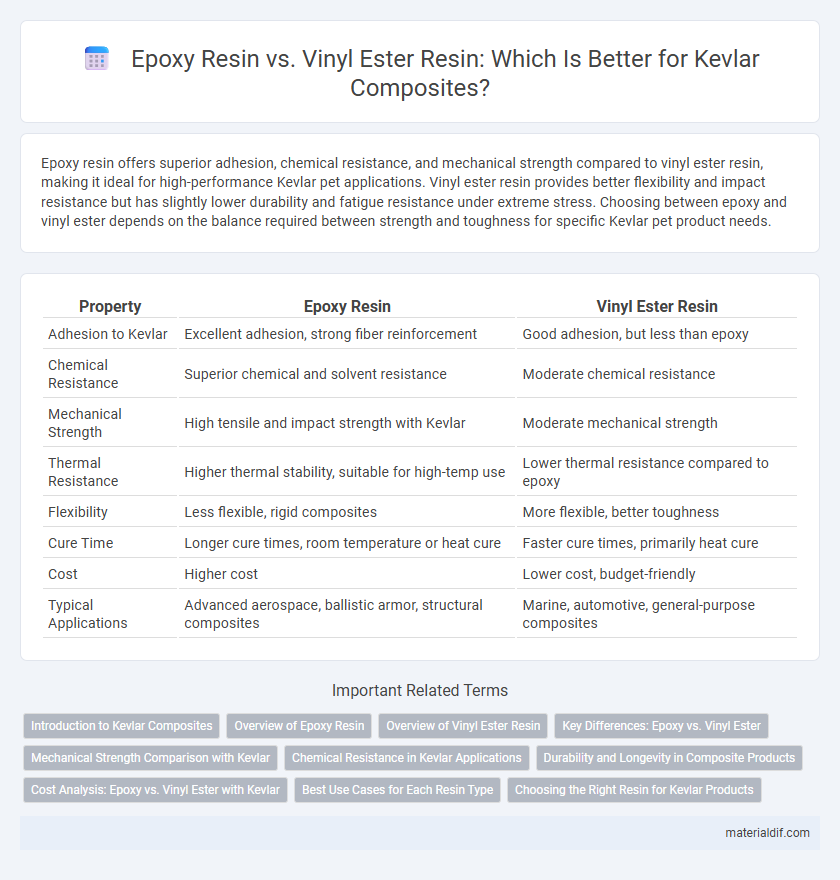

| Property | Epoxy Resin | Vinyl Ester Resin |

|---|---|---|

| Adhesion to Kevlar | Excellent adhesion, strong fiber reinforcement | Good adhesion, but less than epoxy |

| Chemical Resistance | Superior chemical and solvent resistance | Moderate chemical resistance |

| Mechanical Strength | High tensile and impact strength with Kevlar | Moderate mechanical strength |

| Thermal Resistance | Higher thermal stability, suitable for high-temp use | Lower thermal resistance compared to epoxy |

| Flexibility | Less flexible, rigid composites | More flexible, better toughness |

| Cure Time | Longer cure times, room temperature or heat cure | Faster cure times, primarily heat cure |

| Cost | Higher cost | Lower cost, budget-friendly |

| Typical Applications | Advanced aerospace, ballistic armor, structural composites | Marine, automotive, general-purpose composites |

Introduction to Kevlar Composites

Kevlar composites benefit from the choice of matrix resin, where epoxy resin offers superior mechanical strength, excellent adhesion, and chemical resistance compared to vinyl ester resin, making it ideal for high-performance applications. Epoxy resin enhances the toughness and impact resistance of Kevlar composites, contributing to their use in ballistic armor and aerospace components. Vinyl ester resin, while providing good corrosion resistance and cost efficiency, generally exhibits lower durability and thermal stability in Kevlar composite manufacturing.

Overview of Epoxy Resin

Epoxy resin offers superior adhesion, mechanical strength, and chemical resistance compared to vinyl ester resin, making it ideal for high-performance Kevlar composite applications. Its cross-linked polymer structure provides excellent durability and impact resistance, crucial for protective gear and aerospace components. Epoxy's low shrinkage and strong bonding capabilities enhance the structural integrity of Kevlar laminates.

Overview of Vinyl Ester Resin

Vinyl ester resin offers superior chemical resistance and flexibility compared to epoxy resin, making it ideal for Kevlar composite applications requiring enhanced durability and impact resistance. Its molecular structure provides excellent adhesion to Kevlar fibers, promoting improved mechanical strength and corrosion resistance. Vinyl ester resins cure faster and exhibit greater resistance to heat and fatigue, optimizing composite performance in demanding environments.

Key Differences: Epoxy vs. Vinyl Ester

Epoxy resin exhibits superior adhesion, chemical resistance, and mechanical strength compared to vinyl ester resin, making it ideal for high-performance Kevlar composite applications. Vinyl ester resin offers better flexibility and impact resistance but generally has lower heat tolerance and durability than epoxy. Selection between epoxy and vinyl ester resins depends on specific Kevlar composite requirements such as stress resistance, environmental exposure, and cost efficiency.

Mechanical Strength Comparison with Kevlar

Epoxy resin exhibits superior mechanical strength and adhesion with Kevlar fibers, resulting in enhanced impact resistance and tensile strength in composite materials. Vinyl ester resin offers good corrosion resistance and flexibility but generally has lower interfacial bonding strength with Kevlar, leading to reduced load transfer efficiency. Choosing epoxy resin over vinyl ester significantly improves the durability and structural integrity of Kevlar-reinforced composites in high-stress applications.

Chemical Resistance in Kevlar Applications

Epoxy resin exhibits superior chemical resistance in Kevlar applications, effectively withstanding exposure to acids, alkalis, and solvents, thereby enhancing the material's durability in harsh environments. Vinyl ester resin offers moderate chemical resistance but is more prone to degradation compared to epoxy when exposed to aggressive chemicals. Selecting epoxy resin optimizes Kevlar composites for applications requiring long-term exposure to corrosive substances.

Durability and Longevity in Composite Products

Epoxy resin exhibits superior chemical resistance and mechanical strength compared to vinyl ester resin, enhancing the durability of Kevlar composite products in harsh environments. Vinyl ester resin offers good toughness and corrosion resistance but typically shows a shorter service life under prolonged exposure to UV and chemicals. For applications demanding maximum longevity and structural integrity, epoxy resin remains the preferred choice in Kevlar composites.

Cost Analysis: Epoxy vs. Vinyl Ester with Kevlar

Epoxy resin combined with Kevlar generally incurs higher material costs compared to vinyl ester resin due to its superior adhesion properties and chemical resistance. Vinyl ester resin offers a more cost-effective alternative with satisfactory mechanical performance but typically exhibits lower durability and impact resistance when paired with Kevlar. The choice between epoxy and vinyl ester resins for Kevlar composites depends heavily on budget constraints and application-specific performance requirements.

Best Use Cases for Each Resin Type

Epoxy resin provides superior adhesion, chemical resistance, and mechanical properties, making it ideal for high-performance Kevlar composites in aerospace, military armor, and automotive applications requiring maximum strength and durability. Vinyl ester resin offers excellent corrosion resistance and toughness at a lower cost, making it suitable for marine environments, storage tanks, and industrial uses where chemical exposure and impact resistance are critical. Selecting epoxy resin benefits structural Kevlar parts demanding enhanced mechanical integrity, while vinyl ester resin is preferred for Kevlar laminates in harsh chemical or water-exposed conditions.

Choosing the Right Resin for Kevlar Products

Epoxy resin offers superior adhesion and mechanical strength, making it ideal for Kevlar composites requiring high impact resistance and durability. Vinyl ester resin provides excellent corrosion resistance and flexibility, suited for applications where chemical exposure or thermal cycling occurs. Selecting the right resin depends on the specific performance demands of Kevlar products, balancing factors such as tensile strength, environmental resistance, and cost-effectiveness.

Epoxy resin vs Vinyl ester resin Infographic

materialdif.com

materialdif.com