Kevlar filament offers superior strength and durability compared to Kevlar staple fiber, making it ideal for high-performance pet gear and protective equipment. The continuous filament structure provides enhanced tensile strength and resistance to abrasion, ensuring long-lasting protection for pets. Kevlar staple fiber, while still strong, is better suited for applications requiring flexibility and softer textures.

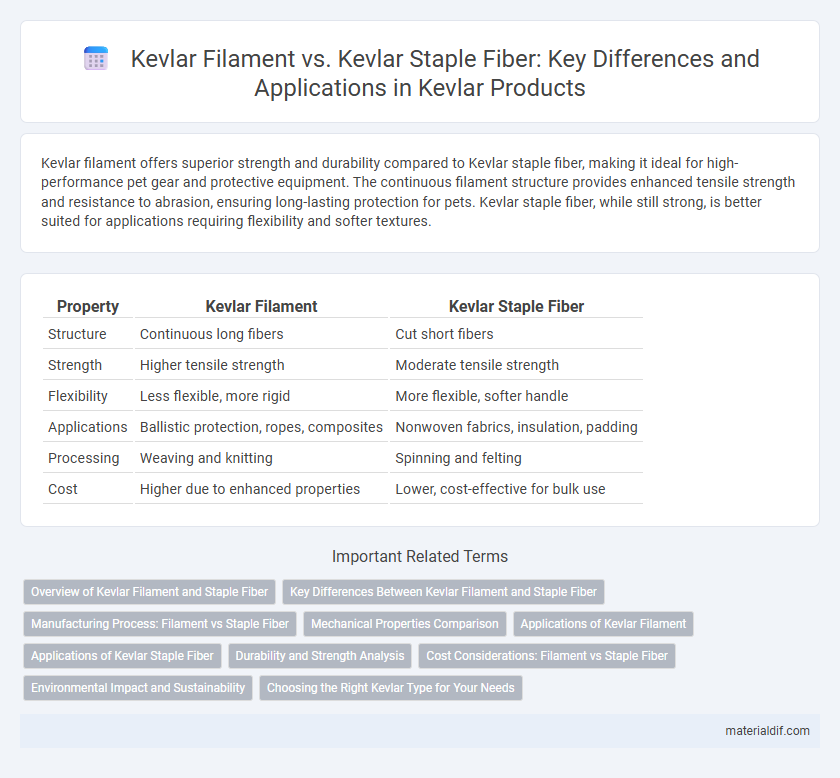

Table of Comparison

| Property | Kevlar Filament | Kevlar Staple Fiber |

|---|---|---|

| Structure | Continuous long fibers | Cut short fibers |

| Strength | Higher tensile strength | Moderate tensile strength |

| Flexibility | Less flexible, more rigid | More flexible, softer handle |

| Applications | Ballistic protection, ropes, composites | Nonwoven fabrics, insulation, padding |

| Processing | Weaving and knitting | Spinning and felting |

| Cost | Higher due to enhanced properties | Lower, cost-effective for bulk use |

Overview of Kevlar Filament and Staple Fiber

Kevlar filament consists of continuous, long fibers that offer superior tensile strength and durability, making them ideal for high-performance applications such as ballistic protection and aerospace components. Kevlar staple fiber, composed of shorter, cut fibers, provides enhanced flexibility and is commonly used in textiles, composites, and reinforcement materials where elasticity and ease of processing are critical. Both forms leverage Kevlar's exceptional heat resistance and chemical stability, but the filament's continuous structure delivers greater structural integrity compared to the staple fiber's versatility and adaptability in fabric manufacturing.

Key Differences Between Kevlar Filament and Staple Fiber

Kevlar filament consists of continuous, long fibers offering superior tensile strength and durability, ideal for high-performance applications like bulletproof vests and aerospace components. Kevlar staple fiber, composed of short, cut lengths of fiber, provides enhanced flexibility and ease of blending with other materials, making it suitable for textiles and composites. The key difference lies in filament's continuous structure delivering maximum strength, while staple fibers prioritize versatility and ease of processing.

Manufacturing Process: Filament vs Staple Fiber

Kevlar filament is produced through a continuous spinning process where polymer chains are aligned and solidified into long, strong fibers, resulting in high tensile strength and uniformity. In contrast, Kevlar staple fiber is created by cutting continuous filaments into shorter lengths, which are then processed into yarns or nonwoven fabrics, offering more flexibility for textiles but less strength compared to filament. The manufacturing distinction impacts Kevlar's performance in applications like ballistic protection, where filament is preferred for maximum durability, while staple fiber suits use in composites and woven materials.

Mechanical Properties Comparison

Kevlar filament exhibits superior tensile strength and elongation at break compared to Kevlar staple fiber, resulting in enhanced load-bearing capacity and resistance to mechanical stress. The continuous filament structure provides higher modulus and better fatigue resistance, while staple fiber's chopped form compromises uniform stress distribution. Consequently, Kevlar filament is preferred in applications requiring maximum mechanical performance such as ballistic protection and composites reinforcement.

Applications of Kevlar Filament

Kevlar filament is widely used in high-performance applications such as ballistic armor, aerospace components, and advanced composites due to its superior tensile strength and continuous fiber structure. Compared to Kevlar staple fiber, filament offers enhanced durability and consistent performance in bulletproof vests, helmets, and reinforcing materials for automotive and marine industries. Its ability to be precisely woven or braided makes Kevlar filament ideal for protective gear and structural reinforcements where maximum strength-to-weight ratio is critical.

Applications of Kevlar Staple Fiber

Kevlar staple fiber, characterized by shorter fiber lengths compared to filament variants, is widely used in applications requiring enhanced flexibility and breathability, such as protective clothing, tire reinforcement, and composite materials in automotive and aerospace industries. Its staple structure allows for better blending with other fibers, improving comfort and durability in textiles and industrial fabrics. The inherent high tensile strength and thermal stability of Kevlar staple fiber contribute to its widespread use in ballistic protection and high-performance filtration systems.

Durability and Strength Analysis

Kevlar filament exhibits superior tensile strength and durability compared to Kevlar staple fiber due to its continuous, unbroken structure, which enhances load-bearing capacity and resistance to abrasion. The filament form maintains higher molecular alignment, resulting in greater impact resistance and longer service life in demanding applications such as ballistic armor and aerospace components. Staple fibers, while versatile and easier to process into textiles, generally have reduced strength and durability because of fiber ends and weaker inter-fiber bonding.

Cost Considerations: Filament vs Staple Fiber

Kevlar filament typically incurs higher production costs compared to Kevlar staple fiber due to its continuous, high-strength fiber structure and more complex manufacturing process. Staple fiber, being shorter and less refined, offers a cost-effective alternative suitable for bulk applications where ultimate tensile strength is less critical. Cost efficiency in Kevlar applications often depends on balancing the superior performance of filaments against the affordability and versatility of staple fibers.

Environmental Impact and Sustainability

Kevlar filament exhibits a more energy-intensive production process compared to Kevlar staple fiber, resulting in a higher carbon footprint per kilogram. Kevlar staple fiber, derived from shorter, chopped fibers, allows for more efficient recycling and reduced waste during manufacturing, enhancing its sustainability profile. Furthermore, staple fiber's adaptability in blended textiles promotes longer product lifespans and supports circular economy initiatives within the textile industry.

Choosing the Right Kevlar Type for Your Needs

Kevlar filament offers superior tensile strength and durability, making it ideal for applications demanding high performance and resistance to wear, such as ballistic protection and aerospace components. Kevlar staple fiber provides greater flexibility and softness, suitable for textile blends and protective clothing requiring comfort and ease of movement. Selecting the right Kevlar type depends on balancing the need for strength versus flexibility based on the end-use requirements.

Kevlar filament vs Kevlar staple fiber Infographic

materialdif.com

materialdif.com