Kevlar pet products offer exceptional abrasive resistance, making them highly durable against scratches and rough surfaces that pets frequently encounter. This material also boasts impressive tensile strength, ensuring it can withstand significant pulling and tugging without tearing or deforming. Combining these properties, Kevlar pet items provide long-lasting protection and reliability for active pets.

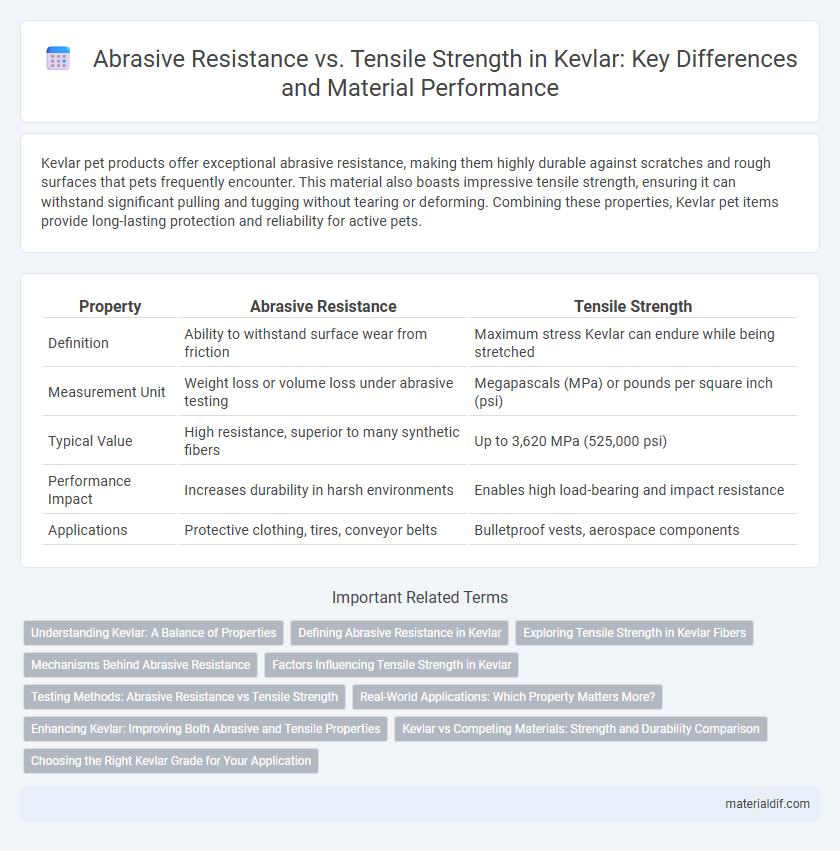

Table of Comparison

| Property | Abrasive Resistance | Tensile Strength |

|---|---|---|

| Definition | Ability to withstand surface wear from friction | Maximum stress Kevlar can endure while being stretched |

| Measurement Unit | Weight loss or volume loss under abrasive testing | Megapascals (MPa) or pounds per square inch (psi) |

| Typical Value | High resistance, superior to many synthetic fibers | Up to 3,620 MPa (525,000 psi) |

| Performance Impact | Increases durability in harsh environments | Enables high load-bearing and impact resistance |

| Applications | Protective clothing, tires, conveyor belts | Bulletproof vests, aerospace components |

Understanding Kevlar: A Balance of Properties

Kevlar exhibits exceptional tensile strength, enabling it to withstand significant pulling forces without breaking, while its abrasive resistance ensures durability against surface wear and friction. The balance between these properties makes Kevlar ideal for applications requiring lightweight materials with high durability, such as body armor and industrial gloves. Optimizing both tensile strength and abrasive resistance enhances Kevlar's performance in protective gear and high-stress environments.

Defining Abrasive Resistance in Kevlar

Abrasive resistance in Kevlar refers to its ability to withstand surface wear and friction without degrading, critical for protective gear exposed to harsh environments. This property is quantified by the material's capacity to resist surface damage while maintaining structural integrity under repeated rubbing or scraping. Higher tensile strength in Kevlar contributes to enhanced abrasive resistance by providing a durable fiber matrix that resists breaking or thinning during abrasion.

Exploring Tensile Strength in Kevlar Fibers

Kevlar fibers exhibit exceptional tensile strength, approximately 3,620 MPa, which enables them to withstand significant stretching forces without breaking. This tensile strength surpasses many other synthetic fibers, making Kevlar ideal for applications requiring durability against mechanical stress. While its abrasive resistance is notable, the unparalleled tensile strength is the primary attribute that defines Kevlar's performance in protective gear and high-stress environments.

Mechanisms Behind Abrasive Resistance

Kevlar's abrasive resistance is primarily attributed to its high molecular alignment and crystallinity, which create a durable surface that resists wear and surface degradation. The tightly packed polymer chains distribute mechanical stress evenly, preventing fiber breakage during abrasive contact. Tensile strength supports this resistance by maintaining fiber integrity under tension, but the abrasion resistance mechanism specifically relies on surface hardness and the polymer's ability to absorb and dissipate frictional energy.

Factors Influencing Tensile Strength in Kevlar

Kevlar's tensile strength is predominantly influenced by its molecular structure, specifically the alignment and crystallinity of its polymer chains, which create strong intermolecular hydrogen bonds. Manufacturing processes like fiber spinning and heat treatment optimize these molecular arrangements, enhancing tensile strength by reducing defects and increasing fiber orientation. Environmental factors such as moisture and temperature can also affect tensile properties by altering the polymer's molecular interactions and flexibility.

Testing Methods: Abrasive Resistance vs Tensile Strength

Abrasive resistance and tensile strength of Kevlar are evaluated using distinct testing methods that measure its durability under different stresses. Abrasive resistance is typically tested through standardized procedures like ASTM D4060, which uses a Taber Abraser to simulate wear and quantify material loss after cycles of friction. Tensile strength testing follows ASTM D3039, where Kevlar fibers are subjected to controlled tension until failure, providing critical data on maximum load capacity and elongation characteristics.

Real-World Applications: Which Property Matters More?

Kevlar's exceptional tensile strength makes it ideal for applications requiring high load-bearing capacity, such as bulletproof vests and aerospace components. In contrast, its abrasive resistance is critical in environments prone to friction and wear, like protective gloves and industrial conveyor belts. Evaluating whether tensile strength or abrasive resistance matters more depends on the specific demand of real-world applications, balancing durability with performance under stress.

Enhancing Kevlar: Improving Both Abrasive and Tensile Properties

Enhancing Kevlar involves optimizing its molecular structure to improve both abrasive resistance and tensile strength, key factors for durability and performance in protective gear and industrial applications. Advanced manufacturing techniques, such as fiber surface treatments and nanocomposite integration, increase abrasion resistance without compromising tensile integrity. These improvements ensure Kevlar maintains high strength while enduring harsh wear conditions, extending its functionality in demanding environments.

Kevlar vs Competing Materials: Strength and Durability Comparison

Kevlar exhibits superior abrasive resistance compared to traditional materials like nylon and polyester, making it ideal for applications requiring durability against wear. Its tensile strength reaches up to 3,620 MPa, significantly outperforming competing fibers such as steel wire (approximately 2,000 MPa) and carbon fiber (2,500-3,000 MPa). This combination of high tensile strength and exceptional abrasion resistance positions Kevlar as a leading choice in protective gear, aerospace, and industrial uses where both strength and long-term durability are critical.

Choosing the Right Kevlar Grade for Your Application

Kevlar's abrasive resistance varies significantly across grades, with Kevlar 29 offering enhanced durability for high-friction environments, while Kevlar 49 provides superior tensile strength ideal for load-bearing applications. Selecting the appropriate Kevlar grade hinges on balancing the need for abrasion resistance against tensile strength requirements specific to industrial, ballistic, or composite material uses. Optimizing application performance involves matching Kevlar's mechanical properties, such as tensile modulus and tear resistance, to operational stress and wear conditions.

Abrasive Resistance vs Tensile Strength Infographic

materialdif.com

materialdif.com