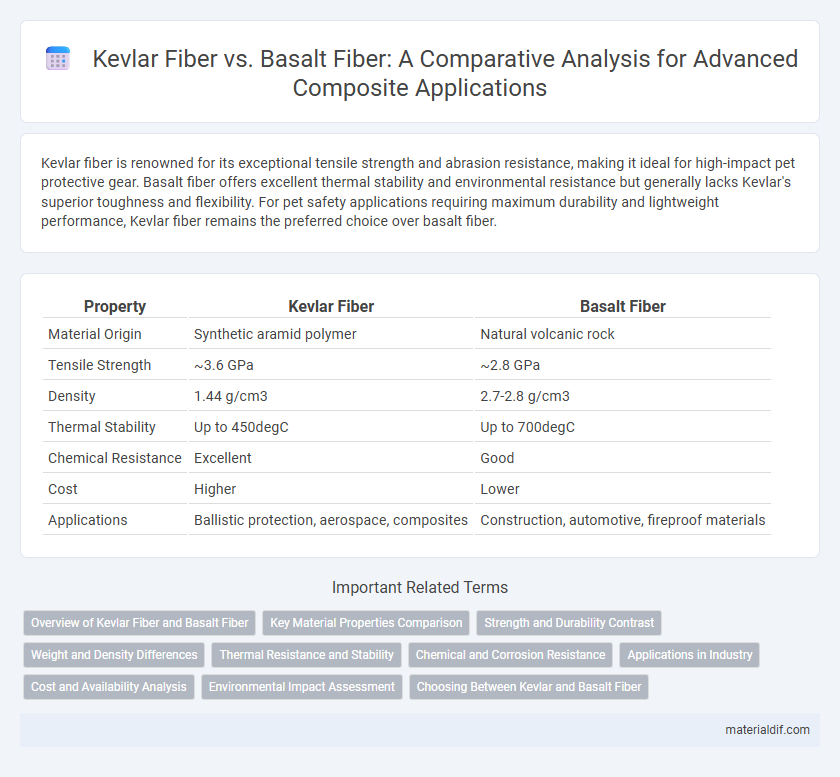

Kevlar fiber is renowned for its exceptional tensile strength and abrasion resistance, making it ideal for high-impact pet protective gear. Basalt fiber offers excellent thermal stability and environmental resistance but generally lacks Kevlar's superior toughness and flexibility. For pet safety applications requiring maximum durability and lightweight performance, Kevlar fiber remains the preferred choice over basalt fiber.

Table of Comparison

| Property | Kevlar Fiber | Basalt Fiber |

|---|---|---|

| Material Origin | Synthetic aramid polymer | Natural volcanic rock |

| Tensile Strength | ~3.6 GPa | ~2.8 GPa |

| Density | 1.44 g/cm3 | 2.7-2.8 g/cm3 |

| Thermal Stability | Up to 450degC | Up to 700degC |

| Chemical Resistance | Excellent | Good |

| Cost | Higher | Lower |

| Applications | Ballistic protection, aerospace, composites | Construction, automotive, fireproof materials |

Overview of Kevlar Fiber and Basalt Fiber

Kevlar fiber, a para-aramid synthetic fiber, is renowned for its exceptional tensile strength-to-weight ratio and high thermal resistance, making it ideal for ballistic and protective applications. Basalt fiber, derived from volcanic basalt rock, offers excellent thermal stability, chemical resistance, and moderate tensile strength, positioning it as a cost-effective alternative in composite materials. Both fibers serve critical roles in advanced engineering, with Kevlar excelling in impact resistance and Basalt providing sustainable, eco-friendly reinforcement.

Key Material Properties Comparison

Kevlar fiber exhibits superior tensile strength of approximately 3,620 MPa compared to basalt fiber's 2,800-4,800 MPa range, while Kevlar offers exceptional impact resistance and lower density at 1.44 g/cm3 versus basalt's higher density around 2.7-2.9 g/cm3. Thermal stability favors basalt fiber with continuous use temperatures up to 650degC, whereas Kevlar fibers degrade above 400degC. Both materials present excellent chemical resistance but Kevlar's elasticity and energy absorption capabilities make it ideal for ballistic and aerospace applications, contrasting basalt fiber's advantage in high-temperature and corrosion-resistant environments.

Strength and Durability Contrast

Kevlar fiber exhibits superior tensile strength, typically around 3,620 MPa, surpassing basalt fiber's range of 2,800 to 3,100 MPa. The aramid structure of Kevlar grants exceptional impact resistance and durability under dynamic loads, while basalt fiber offers enhanced thermal stability and resistance to chemical degradation. Kevlar's lower elongation at break, approximately 2.4%, contributes to its stiffness and long-term performance in demanding applications compared to basalt fiber's higher elasticity.

Weight and Density Differences

Kevlar fiber exhibits a lower density of approximately 1.44 g/cm3 compared to basalt fiber's density range of 2.7 to 2.9 g/cm3, making Kevlar significantly lighter. This lower weight translates to enhanced strength-to-weight ratio in Kevlar, ideal for applications demanding lightweight yet durable materials. Basalt fiber, while denser and heavier, offers superior thermal and chemical resistance but may not be as advantageous in weight-sensitive uses.

Thermal Resistance and Stability

Kevlar fiber exhibits exceptional thermal resistance with a decomposition temperature around 450degC, maintaining structural integrity under high heat, whereas basalt fiber withstands even higher temperatures up to 870degC without significant degradation. Kevlar's thermal stability supports continuous use in applications exposed to elevated temperatures, such as in aerospace and ballistic protection gear. In comparison, basalt fiber offers superior thermal stability and resistance, making it ideal for environments involving direct fire exposure or thermal insulation.

Chemical and Corrosion Resistance

Kevlar fiber exhibits exceptional chemical resistance to a wide range of acids, alkalis, and organic solvents, making it highly durable in corrosive environments. Basalt fiber offers moderate chemical resistance but tends to degrade faster when exposed to strong alkaline or acidic conditions compared to Kevlar. The superior corrosion resistance of Kevlar fiber ensures longer lifespan and reliability in harsh chemical applications.

Applications in Industry

Kevlar fiber excels in aerospace, automotive, and personal protective equipment due to its exceptional tensile strength and impact resistance, making it ideal for ballistic armor and high-performance composites. Basalt fiber offers superior thermal stability and corrosion resistance, leading to widespread use in construction, marine, and insulation industries where environmental durability is critical. Both fibers serve distinct industrial applications driven by their unique mechanical and chemical properties, optimizing performance in specialized fields.

Cost and Availability Analysis

Kevlar fiber generally commands a higher price point compared to basalt fiber due to its complex manufacturing process and established brand value in ballistic and aerospace applications. Basalt fiber offers a cost-effective alternative with wider natural resource availability, sourced from volcanic rock that is abundant and easily processed. The growing production capacity of basalt fiber enhances its market availability, making it a scalable solution for industries seeking lower cost and sustainable reinforcement materials.

Environmental Impact Assessment

Kevlar fiber production relies heavily on petroleum-based chemicals, resulting in higher carbon emissions and energy consumption compared to basalt fiber, which is derived from abundant volcanic rock with minimal processing needs. Basalt fiber exhibits superior biodegradability and poses fewer ecological risks during disposal, making it a more sustainable alternative for composite materials. Life cycle assessments demonstrate basalt fiber's lower environmental footprint, highlighting its potential for greener manufacturing in automotive and construction industries.

Choosing Between Kevlar and Basalt Fiber

Kevlar fiber offers exceptional tensile strength, lightweight properties, and high resistance to impact and heat, making it ideal for ballistic protection and aerospace applications. Basalt fiber provides superior environmental resistance, excellent thermal stability, and is more cost-effective, suitable for construction and automotive industries. Choosing between Kevlar and basalt fiber depends on the specific requirements for strength, cost-efficiency, and exposure conditions in the intended application.

Kevlar Fiber vs Basalt Fiber Infographic

materialdif.com

materialdif.com