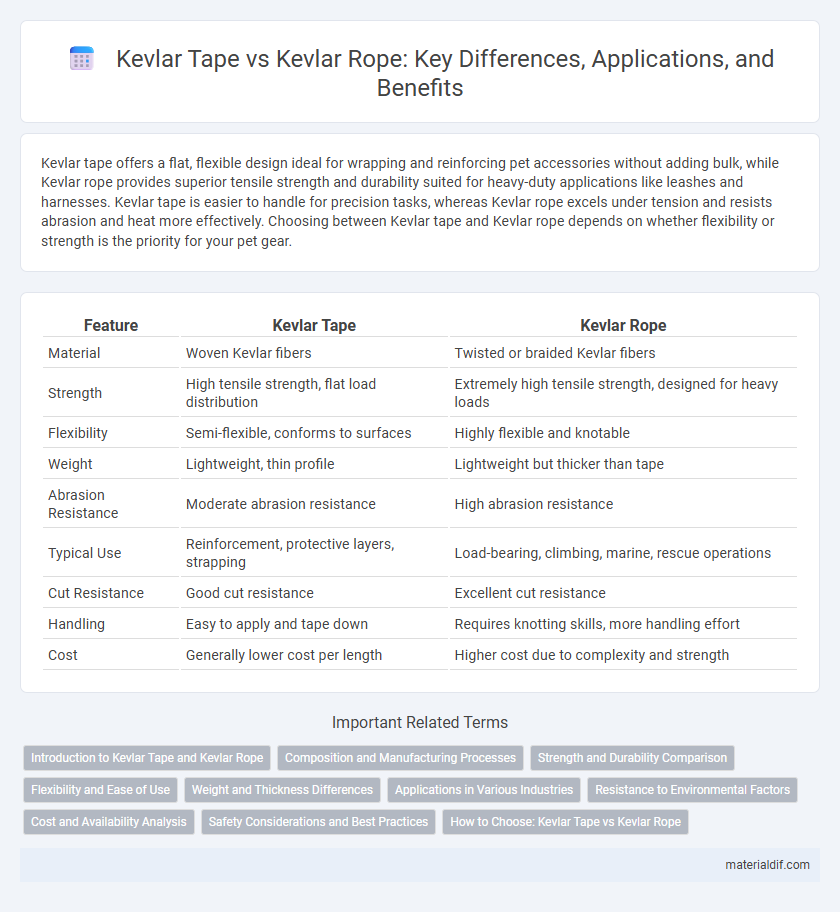

Kevlar tape offers a flat, flexible design ideal for wrapping and reinforcing pet accessories without adding bulk, while Kevlar rope provides superior tensile strength and durability suited for heavy-duty applications like leashes and harnesses. Kevlar tape is easier to handle for precision tasks, whereas Kevlar rope excels under tension and resists abrasion and heat more effectively. Choosing between Kevlar tape and Kevlar rope depends on whether flexibility or strength is the priority for your pet gear.

Table of Comparison

| Feature | Kevlar Tape | Kevlar Rope |

|---|---|---|

| Material | Woven Kevlar fibers | Twisted or braided Kevlar fibers |

| Strength | High tensile strength, flat load distribution | Extremely high tensile strength, designed for heavy loads |

| Flexibility | Semi-flexible, conforms to surfaces | Highly flexible and knotable |

| Weight | Lightweight, thin profile | Lightweight but thicker than tape |

| Abrasion Resistance | Moderate abrasion resistance | High abrasion resistance |

| Typical Use | Reinforcement, protective layers, strapping | Load-bearing, climbing, marine, rescue operations |

| Cut Resistance | Good cut resistance | Excellent cut resistance |

| Handling | Easy to apply and tape down | Requires knotting skills, more handling effort |

| Cost | Generally lower cost per length | Higher cost due to complexity and strength |

Introduction to Kevlar Tape and Kevlar Rope

Kevlar tape is a flat, flexible material made from woven aramid fibers, offering excellent tensile strength and resistance to heat and abrasion, ideal for applications requiring lightweight reinforcement or protective wrapping. Kevlar rope consists of twisted or braided aramid fibers designed to provide superior toughness, high tensile strength, and durability under dynamic loads, commonly used in lifting, climbing, and safety equipment. Both Kevlar tape and rope leverage the inherent properties of aramid fibers but differ in form and application, with tape favoring surface protection and structural reinforcement, while rope is engineered for load-bearing and flexibility.

Composition and Manufacturing Processes

Kevlar tape is made from woven Kevlar fibers that provide a flat, flexible structure ideal for wrapping and reinforcement applications, while Kevlar rope consists of twisted or braided Kevlar yarns designed for high tensile strength and durability in load-bearing contexts. The manufacturing process of Kevlar tape involves weaving the fibers into a tightly knit fabric, enhancing its tear resistance and uniform load distribution, whereas Kevlar rope production emphasizes spinning fibers into yarns and braiding or twisting them to maximize elongation resistance and flexibility. Both products leverage Kevlar's aramid polymer composition, characterized by high tensile strength-to-weight ratio and thermal stability, but their distinct structural designs optimize them for different mechanical performance requirements.

Strength and Durability Comparison

Kevlar tape offers superior tensile strength and excellent abrasion resistance, making it ideal for applications requiring flat, flexible reinforcement with high durability. Kevlar rope, while slightly less resistant to surface wear, provides exceptional load-bearing capacity and flexibility under dynamic stress, maintaining strength over repeated use. Both materials exhibit remarkable durability due to Kevlar's inherent resistance to heat, chemicals, and impact, but tape is preferred for shear strength and structural support, whereas rope excels in tensile strength and knot integrity.

Flexibility and Ease of Use

Kevlar tape offers superior flexibility and conformability, making it ideal for wrapping, bundling, and securing irregular shapes with ease. Kevlar rope provides exceptional tensile strength and durability but is less flexible, potentially limiting its use in applications requiring intricate maneuvering. The choice between Kevlar tape and rope depends on the need for flexibility versus load-bearing capacity in various industrial or safety contexts.

Weight and Thickness Differences

Kevlar tape is significantly lighter and thinner than Kevlar rope, making it ideal for applications requiring minimal bulk and weight. The tape typically measures just a few millimeters in thickness, providing flexibility and ease of handling, while Kevlar rope is thicker and heavier due to its braided construction, designed for high tensile strength and load-bearing capacity. Weight-to-strength ratio favors Kevlar tape in lightweight protective gear and reinforcement, whereas Kevlar rope excels in heavy-duty tasks like climbing and rigging.

Applications in Various Industries

Kevlar tape offers precise cutting and reinforcing applications in aerospace and automotive industries due to its flat, flexible form that enhances material bonding and abrasion resistance. Kevlar rope is preferred in marine, climbing, and military sectors for its exceptional tensile strength, durability, and resistance to heat and chemicals, making it ideal for load-bearing and safety-critical tasks. Both materials leverage Kevlar's high strength-to-weight ratio, but their distinct shapes optimize performance based on specific industrial demands.

Resistance to Environmental Factors

Kevlar tape exhibits superior resistance to moisture, UV radiation, and chemicals compared to conventional rope constructions, making it ideal for harsh environmental conditions. Kevlar rope, while highly durable and strong, may experience some degradation over time when exposed continuously to abrasive surfaces and sunlight without protective coatings. Selecting Kevlar tape over rope enhances longevity and maintains tensile integrity in demanding outdoor or industrial applications.

Cost and Availability Analysis

Kevlar tape typically offers a lower cost per yard compared to Kevlar rope, making it a more budget-friendly option for applications requiring lightweight reinforcement. Kevlar rope, while more expensive due to its complex weaving process, provides superior tensile strength and durability, often justifying the higher price in industrial and safety-critical uses. Availability of Kevlar tape is generally higher in craft and repair markets, whereas Kevlar rope is more specialized and primarily found through industrial suppliers.

Safety Considerations and Best Practices

Kevlar tape offers high tensile strength with excellent abrasion resistance, making it ideal for securing loads without risk of fraying or breakage, while Kevlar rope provides superior flexibility and shock absorption for dynamic loads. Safety considerations emphasize inspecting both materials regularly for wear, avoiding exposure to chemicals that degrade aramid fibers, and selecting the appropriate form based on load type and environmental conditions. Best practices include proper knot techniques with Kevlar rope to maintain strength, and overlapping layering for Kevlar tape to ensure consistent load distribution and prevent slippage.

How to Choose: Kevlar Tape vs Kevlar Rope

Choosing between Kevlar tape and Kevlar rope depends on the intended application and required strength. Kevlar tape offers superior flexibility and abrasion resistance, making it ideal for wrapping and reinforcement tasks, while Kevlar rope excels in tensile strength and durability for load-bearing or climbing uses. Evaluating specific load requirements, environmental exposure, and handling preferences ensures optimal performance when selecting Kevlar materials.

Kevlar tape vs Kevlar rope Infographic

materialdif.com

materialdif.com