Kevlar reinforced plastic offers superior impact resistance and higher tensile strength compared to fiberglass reinforced plastic, making it ideal for applications requiring enhanced durability and toughness. The lightweight nature of Kevlar composites also provides better energy absorption and fatigue resistance, ensuring longer service life under dynamic loads. Fiberglass reinforced plastic, while more cost-effective, generally lacks the advanced mechanical properties and damage tolerance that Kevlar composites deliver.

Table of Comparison

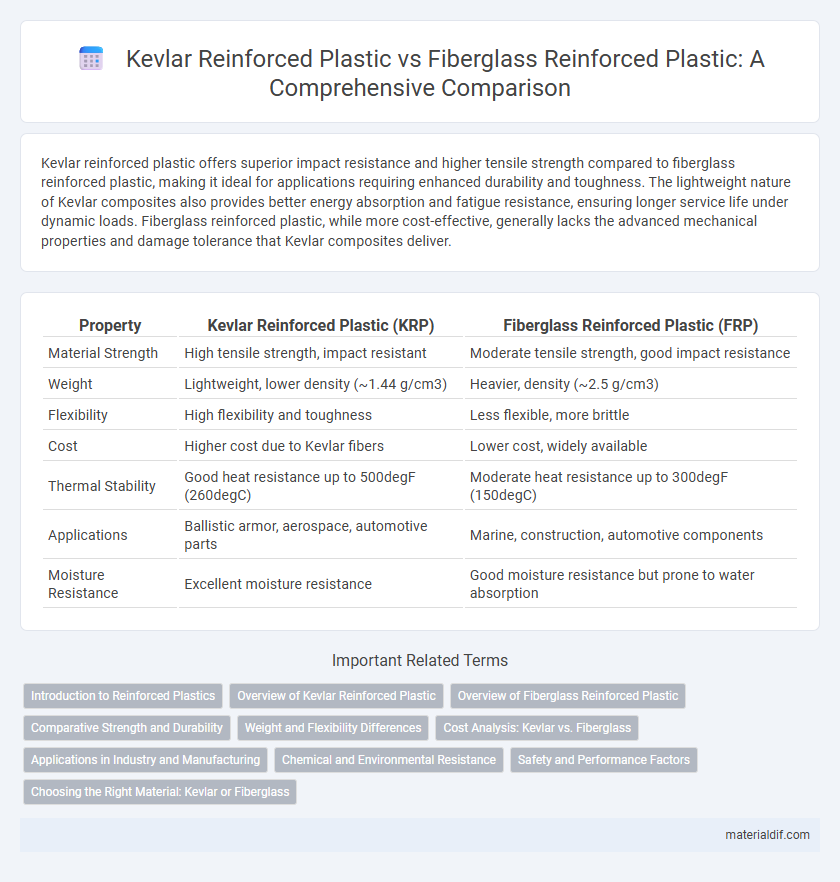

| Property | Kevlar Reinforced Plastic (KRP) | Fiberglass Reinforced Plastic (FRP) |

|---|---|---|

| Material Strength | High tensile strength, impact resistant | Moderate tensile strength, good impact resistance |

| Weight | Lightweight, lower density (~1.44 g/cm3) | Heavier, density (~2.5 g/cm3) |

| Flexibility | High flexibility and toughness | Less flexible, more brittle |

| Cost | Higher cost due to Kevlar fibers | Lower cost, widely available |

| Thermal Stability | Good heat resistance up to 500degF (260degC) | Moderate heat resistance up to 300degF (150degC) |

| Applications | Ballistic armor, aerospace, automotive parts | Marine, construction, automotive components |

| Moisture Resistance | Excellent moisture resistance | Good moisture resistance but prone to water absorption |

Introduction to Reinforced Plastics

Kevlar reinforced plastic (KRP) offers superior tensile strength and impact resistance compared to fiberglass reinforced plastic (FRP), making it ideal for high-performance applications in aerospace and automotive industries. Kevlar fibers provide enhanced durability and weight reduction benefits, improving structural integrity without significantly increasing mass. In contrast, fiberglass reinforced plastic is more cost-effective but generally offers lower strength-to-weight ratios and less resistance to impact and fatigue.

Overview of Kevlar Reinforced Plastic

Kevlar reinforced plastic (KRP) offers superior tensile strength and impact resistance compared to fiberglass reinforced plastic (FRP), making it ideal for applications requiring enhanced durability and lightweight properties. The aramid fibers in Kevlar provide exceptional energy absorption and fatigue resistance, which contribute to improved performance in aerospace, automotive, and ballistic protection industries. KRP composites exhibit better resistance to crack propagation and exhibit a higher strength-to-weight ratio than traditional fiberglass alternatives.

Overview of Fiberglass Reinforced Plastic

Fiberglass reinforced plastic (FRP) consists of glass fibers embedded in a polymer matrix, offering high strength-to-weight ratio and excellent corrosion resistance. Compared to Kevlar reinforced plastic, FRP generally provides greater rigidity and better thermal stability, making it ideal for automotive, marine, and construction applications. Its cost-effectiveness and ease of fabrication contribute to widespread use across industries requiring durable, lightweight composite materials.

Comparative Strength and Durability

Kevlar reinforced plastic exhibits superior tensile strength and impact resistance compared to fiberglass reinforced plastic, making it ideal for applications requiring high durability and lightweight performance. Kevlar composites offer enhanced resistance to fatigue and abrasion, resulting in longer service life under harsh conditions. Fiberglass reinforced plastic, while more cost-effective, typically provides lower strength-to-weight ratios and reduced durability in extreme environments.

Weight and Flexibility Differences

Kevlar reinforced plastic exhibits significantly lower weight and higher tensile strength compared to fiberglass reinforced plastic, making it ideal for applications where weight reduction is critical. Kevlar composites offer superior flexibility due to their molecular structure, allowing better impact resistance and energy absorption. Fiberglass reinforced plastics tend to be heavier and less flexible, which can limit their performance in dynamic or stress-intensive environments.

Cost Analysis: Kevlar vs. Fiberglass

Kevlar reinforced plastic typically incurs higher material costs compared to fiberglass reinforced plastic due to the advanced manufacturing processes and superior tensile strength of Kevlar fibers. While fiberglass offers a more economical solution for large-scale production, Kevlar's enhanced durability and impact resistance can result in lower lifecycle costs for critical applications such as aerospace and military components. Evaluating cost-effectiveness requires balancing initial expenditure against performance benefits, with Kevlar often justified in high-stress environments despite its premium price.

Applications in Industry and Manufacturing

Kevlar reinforced plastic offers superior tensile strength and impact resistance compared to fiberglass reinforced plastic, making it ideal for applications in aerospace, automotive, and military industries where durability and lightweight properties are critical. Its enhanced fatigue resistance and thermal stability provide manufacturers with materials capable of withstanding harsh operational environments, while fiberglass reinforced plastic remains popular for cost-effective structural components in marine and construction sectors. The choice between Kevlar and fiberglass composites depends on balancing performance requirements with budget constraints in industrial and manufacturing processes.

Chemical and Environmental Resistance

Kevlar reinforced plastic exhibits superior chemical resistance compared to fiberglass reinforced plastic, maintaining integrity when exposed to solvents, acids, and alkalis, making it ideal for harsh chemical environments. The aromatic polyamide structure of Kevlar provides enhanced durability against environmental factors like ultraviolet radiation and moisture, reducing degradation over time. Fiberglass, while corrosion-resistant, is more susceptible to alkaline degradation and requires protective coatings for long-term exposure to aggressive chemicals.

Safety and Performance Factors

Kevlar reinforced plastic offers superior impact resistance and tensile strength compared to fiberglass reinforced plastic, enhancing safety in high-stress environments such as automotive and aerospace applications. The lower density of Kevlar composites contributes to better energy absorption and reduced weight, improving overall performance and fuel efficiency. Fire resistance and durability under extreme conditions also make Kevlar reinforced plastics a preferred choice for safety-critical components.

Choosing the Right Material: Kevlar or Fiberglass

Kevlar reinforced plastic offers superior tensile strength and impact resistance compared to fiberglass reinforced plastic, making it ideal for applications requiring high durability and lightweight performance. Fiberglass reinforced plastic provides excellent corrosion resistance and cost-effectiveness, suitable for less demanding environments or budget-conscious projects. Selecting Kevlar or fiberglass depends on balancing factors such as mechanical stress, environmental exposure, and overall project budget.

Kevlar reinforced plastic vs Fiberglass reinforced plastic Infographic

materialdif.com

materialdif.com