Woven Kevlar offers enhanced durability and flexibility by interlacing fibers in multiple directions, making it ideal for protective pet accessories that require resistance to cuts and abrasions. Unidirectional Kevlar features fibers aligned in a single direction, providing superior strength along that axis but less flexibility, suitable for applications needing targeted reinforcement. Choosing between woven and unidirectional Kevlar depends on balancing strength requirements and the desired range of motion for pets.

Table of Comparison

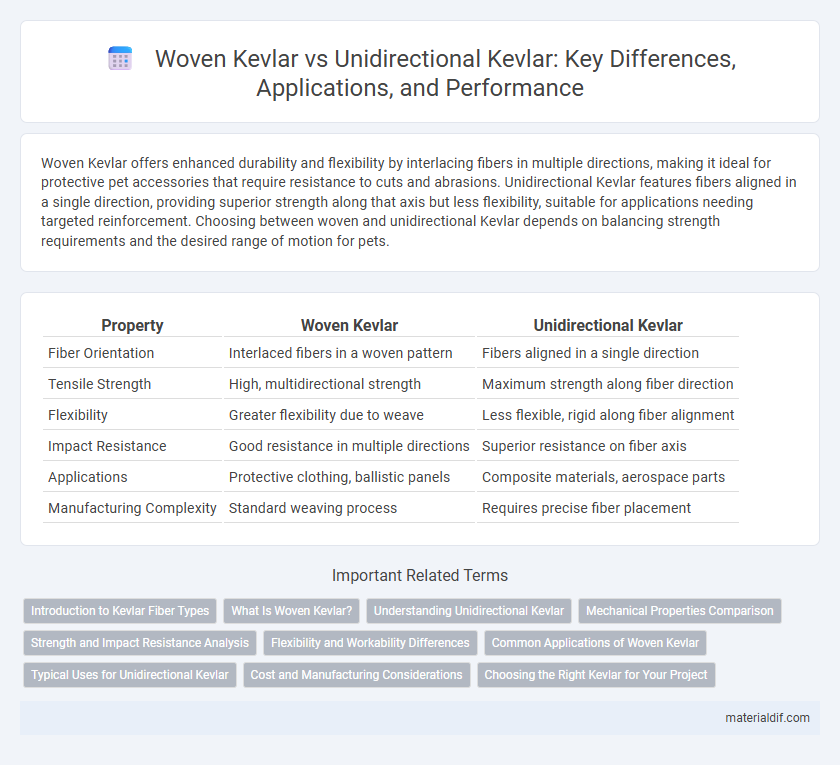

| Property | Woven Kevlar | Unidirectional Kevlar |

|---|---|---|

| Fiber Orientation | Interlaced fibers in a woven pattern | Fibers aligned in a single direction |

| Tensile Strength | High, multidirectional strength | Maximum strength along fiber direction |

| Flexibility | Greater flexibility due to weave | Less flexible, rigid along fiber alignment |

| Impact Resistance | Good resistance in multiple directions | Superior resistance on fiber axis |

| Applications | Protective clothing, ballistic panels | Composite materials, aerospace parts |

| Manufacturing Complexity | Standard weaving process | Requires precise fiber placement |

Introduction to Kevlar Fiber Types

Woven Kevlar consists of interlaced fibers forming a fabric that provides balanced strength and flexibility, making it ideal for applications requiring multidirectional impact resistance. Unidirectional Kevlar features fibers aligned in a single direction, offering maximum tensile strength along that axis, which is crucial for reinforcement in composite materials. Understanding these fiber orientations aids in selecting the appropriate Kevlar type for specific performance requirements in aerospace, automotive, and ballistic protection industries.

What Is Woven Kevlar?

Woven Kevlar consists of interlaced fibers arranged in a crisscross pattern, offering enhanced flexibility and multidirectional strength ideal for protective clothing and ballistic armor. This fabric structure distributes impact forces evenly, improving durability and resistance against cuts and abrasions compared to unidirectional Kevlar, which aligns fibers in a single direction for maximum tensile strength. Woven Kevlar excels in applications requiring balanced protection, combining toughness with comfort and maneuverability.

Understanding Unidirectional Kevlar

Unidirectional Kevlar consists of fibers aligned in a single direction, providing exceptional tensile strength along that axis, making it ideal for applications requiring maximum load support and impact resistance. Unlike woven Kevlar, which interlaces fibers in multiple directions for balanced strength and flexibility, unidirectional Kevlar optimizes fiber alignment to enhance stiffness and energy absorption specifically in the targeted direction. This tailored fiber orientation enhances performance in composites used in aerospace, ballistic armor, and high-performance sporting equipment.

Mechanical Properties Comparison

Woven Kevlar exhibits enhanced impact resistance and multidirectional tensile strength due to its interlaced fiber architecture, providing balanced performance across various stress orientations. Unidirectional Kevlar fibers deliver superior tensile strength and stiffness along a single axis, making them ideal for applications requiring maximum load-bearing capacity in one direction. The choice between woven and unidirectional Kevlar significantly influences mechanical properties such as flexibility, durability, and strength distribution in composite materials.

Strength and Impact Resistance Analysis

Woven Kevlar offers multidirectional strength due to its interlaced fiber structure, providing enhanced impact resistance in various directions. Unidirectional Kevlar aligns fibers in a single direction, delivering superior tensile strength and stiffness along that axis but reduced performance against impacts from alternate angles. The choice between woven and unidirectional Kevlar depends on application requirements prioritizing either uniform impact resistance or maximized directional strength.

Flexibility and Workability Differences

Woven Kevlar consists of interlaced fibers creating a crisscross pattern that offers superior flexibility, making it ideal for applications requiring bending and shaping. In contrast, unidirectional Kevlar has fibers aligned in a single direction, providing higher tensile strength but reduced flexibility and workability. The enhanced flexibility of woven Kevlar facilitates easier handling and conforming to complex geometries, while unidirectional Kevlar excels in scenarios demanding maximum strength along a specific axis.

Common Applications of Woven Kevlar

Woven Kevlar features interlaced fibers that provide multidirectional strength, making it ideal for applications requiring impact resistance and flexibility, such as ballistic body armor, protective gloves, and reinforced composite materials. Its fabric structure allows for better abrasion resistance and durability compared to unidirectional Kevlar, which is primarily used in layered composites for aerospace and industrial applications. Common uses of woven Kevlar include motorcycle apparel, sports equipment, and military protective gear, where a balance of protection and maneuverability is critical.

Typical Uses for Unidirectional Kevlar

Unidirectional Kevlar is primarily used in applications requiring maximum strength along a single axis, such as in aerospace components, sporting equipment like high-performance bicycle frames, and ballistic protection panels. Its fibers align in one direction, offering superior tensile strength and impact resistance compared to woven Kevlar, making it ideal for reinforcing composite materials. Manufacturing processes often incorporate unidirectional Kevlar in layered laminates to optimize load-bearing capacity and durability in critical structural parts.

Cost and Manufacturing Considerations

Woven Kevlar offers greater durability and impact resistance due to its interlaced fiber structure, but it typically costs more to produce because of the complex weaving process and slower manufacturing speed. Unidirectional Kevlar, with fibers aligned in a single direction, is generally less expensive and faster to manufacture, making it suitable for applications requiring high strength in one direction. Manufacturing considerations include equipment requirements, production time, and waste generation, with woven Kevlar necessitating more specialized looms and higher labor intensity compared to unidirectional layup techniques.

Choosing the Right Kevlar for Your Project

Woven Kevlar features interlaced fibers forming a balanced, flexible fabric ideal for applications requiring multi-directional strength, such as protective gear and composite armor. Unidirectional Kevlar consists of parallel fibers aligned in a single direction, offering superior strength and stiffness along that axis, making it perfect for structural reinforcement and load-bearing components. Selecting the right Kevlar depends on project needs: choose woven Kevlar for enhanced durability and impact resistance across varied forces, and unidirectional Kevlar when maximum tensile strength along one direction is essential.

Woven Kevlar vs Unidirectional Kevlar Infographic

materialdif.com

materialdif.com