Kevlar weave consists of interlaced fibers that provide multidirectional strength and enhanced durability, making it ideal for applications requiring impact resistance and flexibility. Kevlar unidirectional fibers are aligned in a single direction, offering superior tensile strength along that axis but less resistance to forces applied from other angles. Choosing between Kevlar weave and unidirectional depends on the specific protection needs of your pet gear, balancing flexibility, weight, and targeted strength.

Table of Comparison

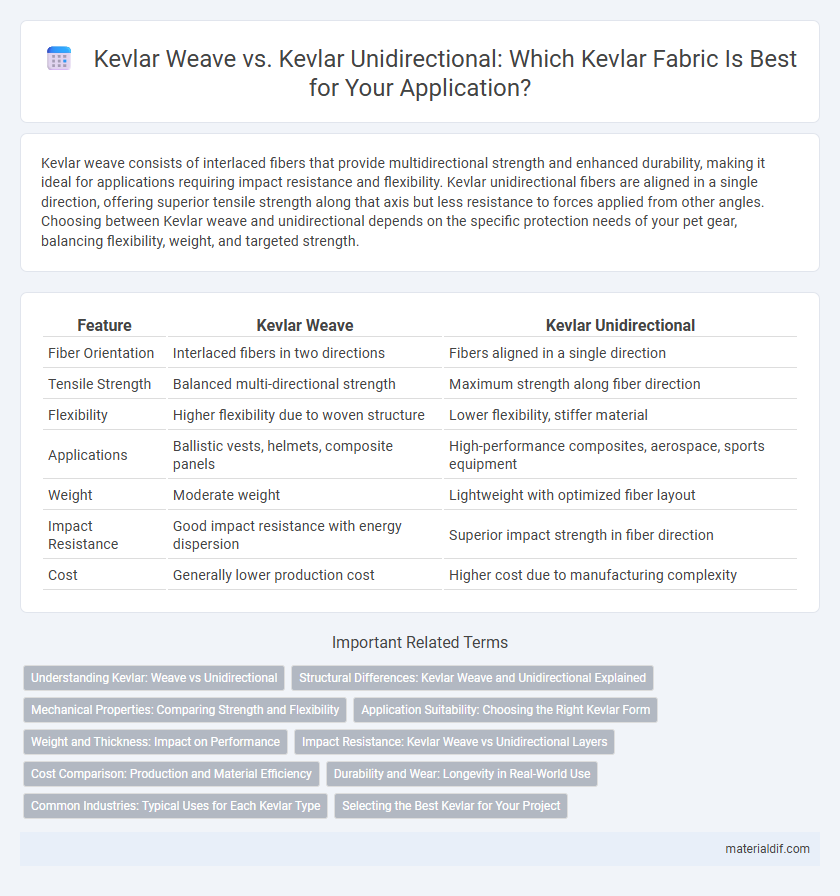

| Feature | Kevlar Weave | Kevlar Unidirectional |

|---|---|---|

| Fiber Orientation | Interlaced fibers in two directions | Fibers aligned in a single direction |

| Tensile Strength | Balanced multi-directional strength | Maximum strength along fiber direction |

| Flexibility | Higher flexibility due to woven structure | Lower flexibility, stiffer material |

| Applications | Ballistic vests, helmets, composite panels | High-performance composites, aerospace, sports equipment |

| Weight | Moderate weight | Lightweight with optimized fiber layout |

| Impact Resistance | Good impact resistance with energy dispersion | Superior impact strength in fiber direction |

| Cost | Generally lower production cost | Higher cost due to manufacturing complexity |

Understanding Kevlar: Weave vs Unidirectional

Kevlar weave consists of interlaced fibers arranged in a crisscross pattern, providing high tensile strength and flexibility, ideal for multi-directional impact resistance in bulletproof vests and composites. Kevlar unidirectional fibers are aligned parallel, offering superior strength and stiffness along a single axis, making them optimal for applications requiring targeted load-bearing capacity such as aerospace components and reinforced panels. Understanding the structural differences between Kevlar weave and unidirectional forms enables engineers to select the best configuration for specific performance requirements in protective gear and advanced materials.

Structural Differences: Kevlar Weave and Unidirectional Explained

Kevlar weave consists of interlaced fibers forming a crisscross pattern, providing multi-directional strength and flexibility ideal for impact resistance. In contrast, Kevlar unidirectional features fibers aligned parallel in a single direction, offering superior tensile strength along that axis but less shear resistance. The structural difference affects performance, with woven Kevlar excelling in abrasion and puncture protection, while unidirectional Kevlar delivers enhanced load-bearing capacity in composite laminates.

Mechanical Properties: Comparing Strength and Flexibility

Kevlar weave exhibits enhanced multidirectional strength due to its interlaced fiber structure, providing superior impact resistance and durability in applications requiring balanced load distribution. In contrast, Kevlar unidirectional fibers offer higher tensile strength along a single axis with greater flexibility, making them ideal for components subjected to linear stress. The choice between Kevlar weave and unidirectional configurations depends on the mechanical demands of strength anisotropy and flexibility in specific engineering applications.

Application Suitability: Choosing the Right Kevlar Form

Kevlar weave offers multi-directional strength and flexibility, making it ideal for applications such as body armor, helmets, and composite panels where impact resistance and durability are critical. Kevlar unidirectional fibers provide superior tensile strength along a single axis, suitable for high-performance sporting equipment, aerospace components, and structures requiring precise load-bearing capacity. Selecting the appropriate Kevlar form depends on the specific stress patterns and performance demands of the application to optimize protection and structural integrity.

Weight and Thickness: Impact on Performance

Kevlar weave offers a balanced combination of weight and thickness that provides multidirectional strength, enhancing impact resistance and durability in protective gear. Kevlar unidirectional fibers are typically lighter and thinner, concentrating strength along a single axis, which optimizes performance in applications requiring directional stress management. The choice between Kevlar weave and unidirectional material directly influences the overall weight and thickness, affecting flexibility, comfort, and level of protection in ballistic and composite armor designs.

Impact Resistance: Kevlar Weave vs Unidirectional Layers

Kevlar weave offers multidirectional fiber alignment, enhancing impact resistance by distributing force across a broader area and reducing localized stress. Unidirectional Kevlar layers provide high strength along a single axis but may have reduced performance against impacts from varying directions. The choice between weave and unidirectional layers depends on the specific application's need for balanced protection versus directional strength.

Cost Comparison: Production and Material Efficiency

Kevlar weave typically involves interlacing fibers in a crisscross pattern, enhancing durability but increasing material use and production complexity, leading to higher costs. Kevlar unidirectional aligns fibers in a single direction, optimizing material efficiency and reducing waste, resulting in lower production expenses. Cost comparison reveals unidirectional Kevlar offers more economical scalability for applications requiring targeted strength, while woven Kevlar suits scenarios demanding multidirectional stress resistance despite the premium.

Durability and Wear: Longevity in Real-World Use

Kevlar weave features interlaced fibers that provide enhanced durability and resistance to abrasion, making it ideal for applications requiring longevity under continuous wear. In contrast, Kevlar unidirectional layers have fibers aligned in a single direction, offering superior strength along that axis but potentially less durability against multidirectional stresses and wear. Real-world use shows that Kevlar weave generally outperforms unidirectional Kevlar in terms of long-term wear resistance and lifespan in environments with frequent mechanical abrasion.

Common Industries: Typical Uses for Each Kevlar Type

Kevlar weave is commonly used in automotive and aerospace industries for applications requiring multidirectional strength, such as body armor, helmets, and structural components. Kevlar unidirectional fibers are preferred in sporting goods and marine industries where high tensile strength in a single direction enhances performance in boat hulls, skis, and high-performance bicycle frames. Both types capitalize on Kevlar's lightweight and impact resistance but serve distinct roles based on fiber orientation and load requirements.

Selecting the Best Kevlar for Your Project

When selecting the best Kevlar for your project, consider that Kevlar weave offers multidirectional strength and durability, making it ideal for impact resistance and flexibility in composite applications. Kevlar unidirectional, on the other hand, provides superior tensile strength along a single axis, perfect for structural components requiring maximum load-bearing capacity. Evaluating project requirements such as load direction, impact resilience, and design complexity will guide the choice between Kevlar weave and unidirectional fibers.

Kevlar weave vs Kevlar unidirectional Infographic

materialdif.com

materialdif.com