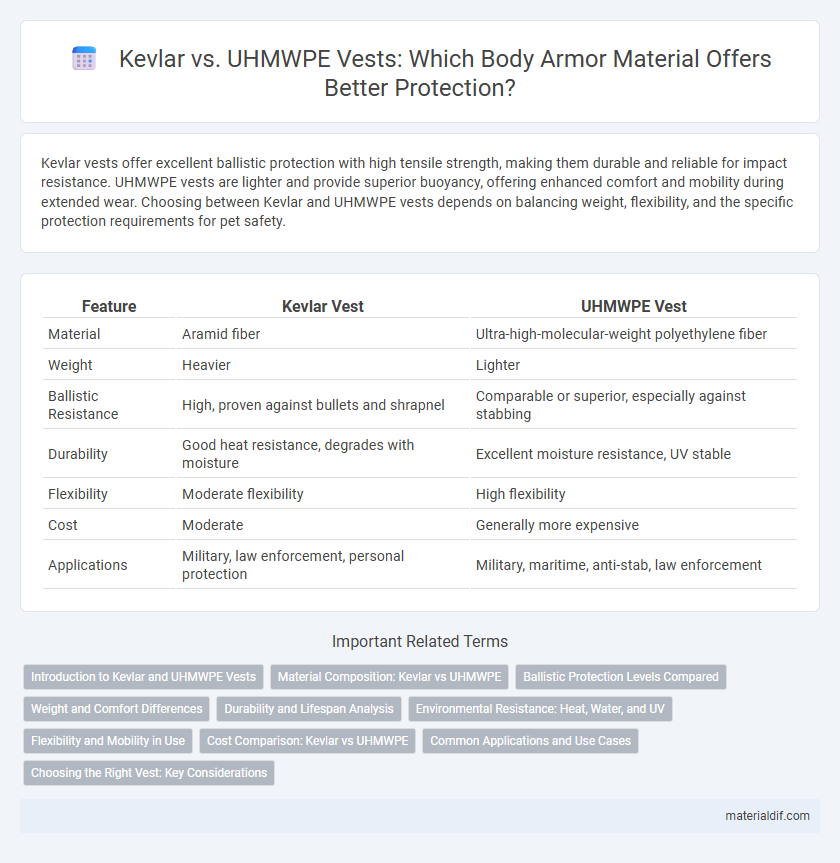

Kevlar vests offer excellent ballistic protection with high tensile strength, making them durable and reliable for impact resistance. UHMWPE vests are lighter and provide superior buoyancy, offering enhanced comfort and mobility during extended wear. Choosing between Kevlar and UHMWPE vests depends on balancing weight, flexibility, and the specific protection requirements for pet safety.

Table of Comparison

| Feature | Kevlar Vest | UHMWPE Vest |

|---|---|---|

| Material | Aramid fiber | Ultra-high-molecular-weight polyethylene fiber |

| Weight | Heavier | Lighter |

| Ballistic Resistance | High, proven against bullets and shrapnel | Comparable or superior, especially against stabbing |

| Durability | Good heat resistance, degrades with moisture | Excellent moisture resistance, UV stable |

| Flexibility | Moderate flexibility | High flexibility |

| Cost | Moderate | Generally more expensive |

| Applications | Military, law enforcement, personal protection | Military, maritime, anti-stab, law enforcement |

Introduction to Kevlar and UHMWPE Vests

Kevlar vests are made from aramid fibers known for their high tensile strength-to-weight ratio, providing excellent ballistic protection and resistance against sharp objects. UHMWPE (Ultra-High Molecular Weight Polyethylene) vests utilize ultra-fine polyethylene fibers that offer superior lightweight durability and enhanced impact absorption. Both materials are widely used in body armor, with Kevlar favored for its heat resistance and UHMWPE recognized for its exceptional strength-to-weight efficiency.

Material Composition: Kevlar vs UHMWPE

Kevlar vests are composed of aramid fibers known for their high tensile strength and heat resistance, making them effective against ballistic threats. UHMWPE vests utilize ultra-high-molecular-weight polyethylene fibers, which offer a lighter weight and greater resistance to moisture and chemicals while maintaining ballistic protection. The molecular structure of UHMWPE provides superior impact energy absorption compared to Kevlar, influencing the vest's flexibility and durability in various operational environments.

Ballistic Protection Levels Compared

Kevlar vests provide reliable ballistic protection primarily at NIJ Level II and IIIA, effectively stopping handgun rounds but limited against rifle rounds. UHMWPE vests excel in higher ballistic protection levels, often rated up to NIJ Level III and IV, capable of stopping rifle ammunition while being lighter and more flexible. The choice between Kevlar and UHMWPE vests depends on required threat level protection, weight preference, and operational environment.

Weight and Comfort Differences

Kevlar vests typically weigh more than UHMWPE vests due to the denser aramid fibers used in Kevlar construction, impacting overall comfort during extended wear. UHMWPE vests offer enhanced comfort by being lighter and more flexible, reducing fatigue and allowing greater mobility. The weight difference can be significant, with UHMWPE vests often 20-30% lighter, making them preferable for long-duration use in tactical scenarios.

Durability and Lifespan Analysis

Kevlar vests exhibit exceptional durability due to their high tensile strength and resistance to impact, often maintaining protective qualities over extended periods under typical use conditions. UHMWPE vests show superior resistance to environmental factors like moisture and UV exposure, which can degrade Kevlar fibers, thus potentially offering a longer effective lifespan in harsh climates. The lifespan of Kevlar vests typically ranges from 5 to 10 years depending on maintenance, while UHMWPE vests can extend this range slightly due to their enhanced environmental resilience.

Environmental Resistance: Heat, Water, and UV

Kevlar vests exhibit excellent heat resistance, maintaining structural integrity up to 450degC, but degrade under prolonged UV exposure and absorb moisture, which can reduce performance. UHMWPE vests offer superior water resistance and do not absorb moisture, preserving buoyancy and stability in wet conditions, although their heat tolerance is lower, typically softening around 80degC. Both materials require protective coatings to enhance UV stability, but Kevlar's heat resistance makes it preferable in high-temperature environments, while UHMWPE excels in aquatic or humid conditions.

Flexibility and Mobility in Use

Kevlar vests offer superior flexibility due to their woven aramid fibers, allowing for greater mobility during extended wear or dynamic movements. UHMWPE vests, while lightweight and providing high ballistic resistance, tend to be stiffer, which can limit flexibility and reduce comfort in prolonged use. The enhanced pliability of Kevlar makes it a preferred choice for applications requiring agility and ease of movement.

Cost Comparison: Kevlar vs UHMWPE

Kevlar vests generally cost less than UHMWPE (Ultra-High-Molecular-Weight Polyethylene) vests due to the established manufacturing processes and widespread availability of aramid fibers. UHMWPE vests, while offering superior lightweight and ballistic performance, often come at a higher price point because of advanced polymer production techniques and material costs. The price difference can influence procurement decisions for law enforcement and military agencies balancing budget constraints with protective effectiveness.

Common Applications and Use Cases

Kevlar vests are widely used by military personnel, law enforcement officers, and security forces due to their excellent ballistic resistance and durability in high-impact situations. UHMWPE (Ultra-High-Molecular-Weight Polyethylene) vests are favored in scenarios requiring lighter, more flexible armor such as patrol or undercover operations, offering superior comfort without compromising protection against low- to medium-velocity threats. Both materials are commonly utilized in personal protective equipment for tactical missions, bomb disposal, and civilian body armor, prioritizing different operational needs based on weight, flexibility, and threat level.

Choosing the Right Vest: Key Considerations

Kevlar vests offer high tensile strength and proven durability, making them effective against ballistic threats, while UHMWPE vests provide lighter weight and better resistance to blunt force trauma. When choosing the right vest, prioritize factors such as threat level, comfort, weight, and environmental resistance, as UHMWPE may degrade under UV exposure unlike Kevlar. Understanding operational requirements and intended use ensures optimal protection and performance between Kevlar and UHMWPE body armor options.

Kevlar vest vs UHMWPE vest Infographic

materialdif.com

materialdif.com