Kevlar weave consists of interlaced fibers forming a flexible and breathable material, ideal for pet gear requiring durability and comfort. Kevlar laminate features a solid layer bonded to other materials, offering enhanced protection against punctures and abrasions but less flexibility. Choosing between Kevlar weave and laminate depends on the balance needed between flexibility and maximum protective strength for pet equipment.

Table of Comparison

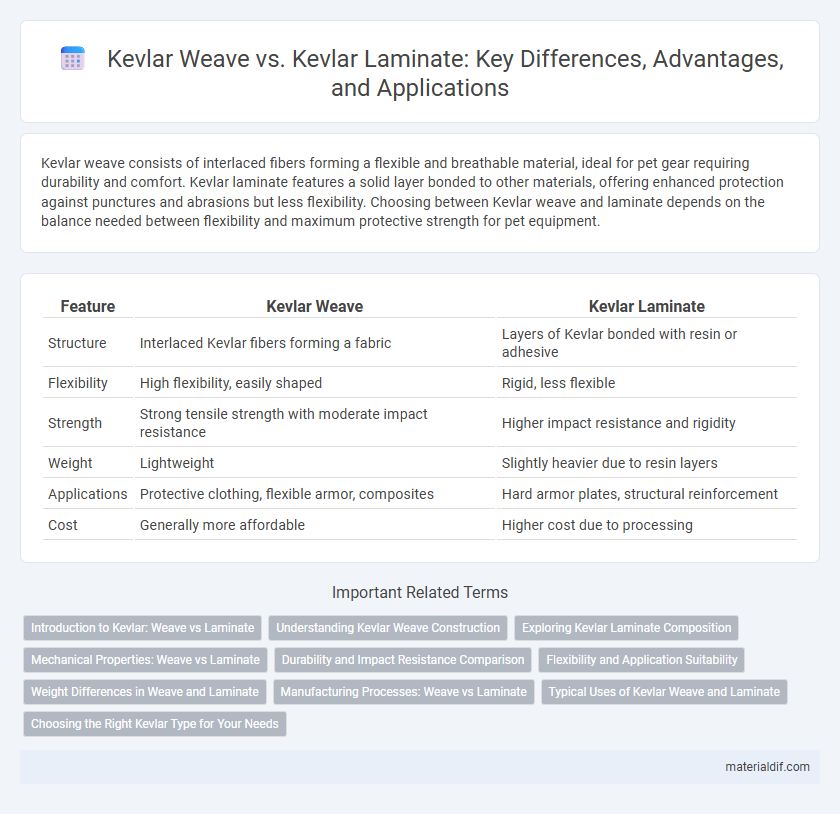

| Feature | Kevlar Weave | Kevlar Laminate |

|---|---|---|

| Structure | Interlaced Kevlar fibers forming a fabric | Layers of Kevlar bonded with resin or adhesive |

| Flexibility | High flexibility, easily shaped | Rigid, less flexible |

| Strength | Strong tensile strength with moderate impact resistance | Higher impact resistance and rigidity |

| Weight | Lightweight | Slightly heavier due to resin layers |

| Applications | Protective clothing, flexible armor, composites | Hard armor plates, structural reinforcement |

| Cost | Generally more affordable | Higher cost due to processing |

Introduction to Kevlar: Weave vs Laminate

Kevlar weave consists of interlaced fibers forming a strong, flexible fabric commonly used in protective clothing and composite materials for impact resistance. Kevlar laminate comprises multiple layers of Kevlar fabric bonded with resin, offering enhanced rigidity and ballistic protection in helmets and body armor. Choosing between Kevlar weave and laminate depends on specific performance needs such as flexibility, durability, and impact absorption.

Understanding Kevlar Weave Construction

Kevlar weave construction involves interlacing individual Kevlar fibers into a fabric, creating a flexible, durable material that offers high tensile strength and impact resistance. This woven structure enhances breathability and conformability, making it ideal for protective gear like body armor and helmets. In contrast, Kevlar laminate layers pre-impregnated Kevlar fabric with resins, providing rigid, composite protection but less flexibility than woven Kevlar.

Exploring Kevlar Laminate Composition

Kevlar laminate composition consists of multiple layers of Kevlar fabric bonded together with resin or adhesive to form a solid, durable sheet that enhances impact resistance and structural integrity. Unlike Kevlar weave, which retains the fabric's flexibility and open texture, Kevlar laminate offers increased rigidity and superior protection against punctures and abrasions. This composite structure optimizes Kevlar's tensile strength and ballistic properties for applications in body armor, aerospace, and industrial equipment.

Mechanical Properties: Weave vs Laminate

Kevlar weave offers superior tensile strength and flexibility due to its interlaced fiber structure, enabling enhanced impact resistance and energy absorption. Kevlar laminate, composed of layers bonded with resin, provides higher rigidity and improved dimensional stability, making it ideal for load-bearing applications. The choice between weave and laminate depends on the balance between flexibility and stiffness required for specific mechanical performance.

Durability and Impact Resistance Comparison

Kevlar weave offers superior durability due to its interlaced fiber construction, which allows for better flexibility and resistance to tears under stress. Kevlar laminate, however, provides enhanced impact resistance by bonding multiple layers to create a rigid and dense barrier against high-velocity impacts. The choice between Kevlar weave and laminate depends on balancing the need for flexibility with the requirement for maximum protective strength.

Flexibility and Application Suitability

Kevlar weave offers superior flexibility due to its interlaced fiber structure, making it ideal for applications requiring mobility and comfort, such as body armor and protective clothing. Kevlar laminate, composed of layered sheets bonded together, provides enhanced rigidity and impact resistance, suitable for structural reinforcement and ballistic panels. Selecting between Kevlar weave and laminate depends on balancing flexibility needs with the desired level of protection and durability in specific applications.

Weight Differences in Weave and Laminate

Kevlar weave consists of interlaced fibers forming a flexible fabric, resulting in a lighter weight material ideal for applications requiring flexibility and durability. Kevlar laminate is produced by bonding multiple layers of Kevlar fabric with resin, creating a denser and heavier composite with enhanced structural rigidity and impact resistance. Consequently, Kevlar weave tends to be significantly lighter compared to Kevlar laminate, which adds weight due to the resin layers and increased thickness.

Manufacturing Processes: Weave vs Laminate

Kevlar weave manufacturing involves interlacing strong aramid fibers in a crisscross pattern, creating a flexible, durable fabric optimized for impact resistance and tensile strength. Kevlar laminate production fuses multiple Kevlar layers with resins under heat and pressure, resulting in a rigid, dense composite material ideal for ballistic protection and structural reinforcement. Differences in these processes influence the final product's flexibility, weight, and protective capabilities.

Typical Uses of Kevlar Weave and Laminate

Kevlar weave is commonly used in ballistic body armor, helmets, and protective clothing where flexibility and impact resistance are critical. Kevlar laminate is favored in aerospace panels, automotive components, and protective gear due to its superior tensile strength and lightweight, rigid structure. Both forms offer exceptional durability, but the weave provides enhanced mobility while laminate delivers maximum structural integrity.

Choosing the Right Kevlar Type for Your Needs

Kevlar weave offers superior flexibility and breathability, making it ideal for applications requiring comfort and movement, such as protective clothing and gear. Kevlar laminate provides enhanced impact resistance and weatherproofing due to its layered structure, better suited for ballistic armor and high-strength panels. Selecting between Kevlar weave and laminate depends on the balance needed between durability, flexibility, and environmental protection for your specific use case.

Kevlar Weave vs Kevlar Laminate Infographic

materialdif.com

materialdif.com