Kevlar strands provide exceptional tensile strength and flexibility, making them ideal for precise, lightweight applications in pet accessories. Kevlar ropes are constructed by weaving multiple strands together, resulting in a thicker, more durable product suitable for heavy-duty use and increased abrasion resistance. Choosing between a Kevlar strand and Kevlar rope depends on the specific pet gear requirement for strength, flexibility, and durability.

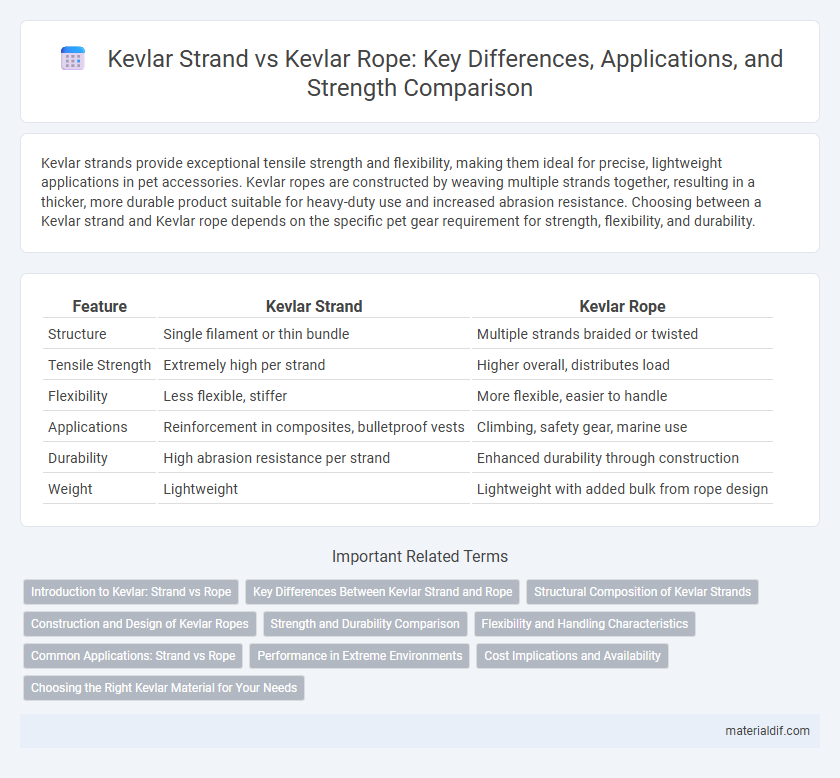

Table of Comparison

| Feature | Kevlar Strand | Kevlar Rope |

|---|---|---|

| Structure | Single filament or thin bundle | Multiple strands braided or twisted |

| Tensile Strength | Extremely high per strand | Higher overall, distributes load |

| Flexibility | Less flexible, stiffer | More flexible, easier to handle |

| Applications | Reinforcement in composites, bulletproof vests | Climbing, safety gear, marine use |

| Durability | High abrasion resistance per strand | Enhanced durability through construction |

| Weight | Lightweight | Lightweight with added bulk from rope design |

Introduction to Kevlar: Strand vs Rope

Kevlar strands consist of individual filaments known for their exceptional tensile strength and lightweight properties, making them ideal for reinforcing materials in high-performance applications. Kevlar ropes are constructed by braiding or twisting multiple Kevlar strands, which enhances durability, flexibility, and load-bearing capacity for demanding tasks such as climbing, marine use, and industrial lifting. The choice between Kevlar strand and rope depends on the specific requirements of strength, flexibility, and application environment.

Key Differences Between Kevlar Strand and Rope

Kevlar strands are individual fibers known for their high tensile strength and flexibility, used primarily in composite materials and specialized textile applications. Kevlar ropes, on the other hand, consist of multiple strands braided or twisted together, offering enhanced durability, abrasion resistance, and load-bearing capacity suitable for industrial and safety uses. The key differences lie in construction, mechanical performance, and specific applications, with strands providing precision strength and ropes delivering robust, versatile performance.

Structural Composition of Kevlar Strands

Kevlar strands consist of tightly aligned poly-paraphenylene terephthalamide fibers, providing exceptional tensile strength and flexibility essential for high-performance applications. Each strand's molecular structure features strong hydrogen bonding and aromatic amide linkages, which contribute to its lightweight yet resilient nature. In contrast, Kevlar ropes are comprised of multiple intertwined strands, enhancing overall durability and load distribution while maintaining the intrinsic strength of individual Kevlar fibers.

Construction and Design of Kevlar Ropes

Kevlar strands consist of multiple ultra-high-molecular-weight polyethylene fibers aligned parallel to provide exceptional tensile strength and minimal stretch. Kevlar ropes are constructed by braiding or twisting these strands together, enhancing flexibility, durability, and load distribution for diverse industrial applications. The rope design incorporates protective coatings or sheaths to resist abrasion, UV exposure, and chemical damage, extending the lifespan of the Kevlar material.

Strength and Durability Comparison

Kevlar strands offer exceptional tensile strength and flexibility on a micro scale, making them ideal for precise applications requiring high strength-to-weight ratios. Kevlar ropes, constructed by braiding multiple strands, provide superior durability and abrasion resistance, enabling them to withstand harsh environmental conditions and intense physical wear. The rope's woven structure enhances load distribution and impact absorption, resulting in greater overall strength and extended lifespan compared to individual Kevlar strands.

Flexibility and Handling Characteristics

Kevlar strands provide enhanced flexibility due to their thinner, more pliable structure, allowing for precise handling in applications requiring intricate maneuvering. Kevlar ropes, composed of multiple strands braided together, offer superior strength and abrasion resistance but tend to be stiffer, impacting overall flexibility and ease of handling. The choice between Kevlar strand and rope depends on balancing the need for flexibility with the demand for tensile strength in specific environments.

Common Applications: Strand vs Rope

Kevlar strands are typically used in high-strength composite materials, body armor, and fishing lines due to their flexibility and tensile strength. Kevlar ropes, constructed by twisting multiple strands, find common applications in marine environments, rescue operations, and industrial lifting because of their enhanced durability and load-bearing capacity. The choice between Kevlar strand and rope depends on specific requirements like flexibility, strength, and environmental resistance.

Performance in Extreme Environments

Kevlar strand exhibits superior tensile strength and heat resistance compared to standard fibers, making it ideal for reinforcement in composite materials exposed to extreme conditions. Kevlar rope, constructed by twisting multiple strands, offers enhanced flexibility and abrasion resistance, crucial for applications involving dynamic loads and sharp environments. Both forms maintain exceptional durability against chemical corrosion and UV degradation, ensuring reliable performance in harsh industrial, marine, and aerospace settings.

Cost Implications and Availability

Kevlar strands are typically less expensive than Kevlar ropes due to simpler manufacturing processes and lower material usage, making them more cost-effective for applications requiring high tensile strength with minimal bulk. Kevlar ropes, while more costly, offer enhanced durability and flexibility essential for demanding industrial or marine uses, but their availability can be limited by specialized production facilities. Cost implications also depend on market demand, with Kevlar strands generally more widely available and easier to source from multiple suppliers compared to the niche supply of Kevlar ropes.

Choosing the Right Kevlar Material for Your Needs

Kevlar strands offer exceptional tensile strength and flexibility, making them ideal for applications requiring precision and lightweight reinforcement. Kevlar ropes provide enhanced durability and abrasion resistance, suited for heavy-duty tasks such as climbing, marine use, and industrial safety. Selecting the right Kevlar material depends on the specific strength requirements, environmental exposure, and flexibility needed for your project.

Kevlar strand vs Kevlar rope Infographic

materialdif.com

materialdif.com