Kevlar thread offers superior flexibility and lightweight strength compared to stainless steel thread, making it ideal for durable pet accessories that require comfort and resilience. Unlike stainless steel, Kevlar is resistant to corrosion and abrasion, ensuring long-lasting performance in various environmental conditions. Its high tensile strength combined with low weight enhances both the safety and comfort of pets wearing Kevlar-based gear.

Table of Comparison

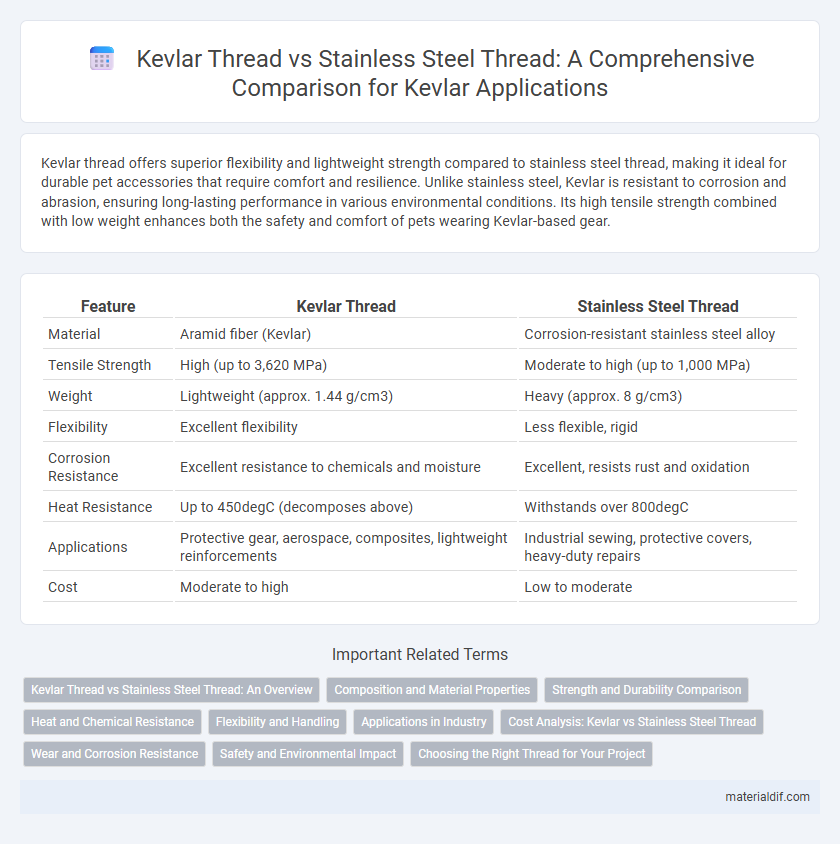

| Feature | Kevlar Thread | Stainless Steel Thread |

|---|---|---|

| Material | Aramid fiber (Kevlar) | Corrosion-resistant stainless steel alloy |

| Tensile Strength | High (up to 3,620 MPa) | Moderate to high (up to 1,000 MPa) |

| Weight | Lightweight (approx. 1.44 g/cm3) | Heavy (approx. 8 g/cm3) |

| Flexibility | Excellent flexibility | Less flexible, rigid |

| Corrosion Resistance | Excellent resistance to chemicals and moisture | Excellent, resists rust and oxidation |

| Heat Resistance | Up to 450degC (decomposes above) | Withstands over 800degC |

| Applications | Protective gear, aerospace, composites, lightweight reinforcements | Industrial sewing, protective covers, heavy-duty repairs |

| Cost | Moderate to high | Low to moderate |

Kevlar Thread vs Stainless Steel Thread: An Overview

Kevlar thread offers high tensile strength and exceptional resistance to heat and chemicals compared to stainless steel thread, making it ideal for applications requiring lightweight and durable reinforcement. While stainless steel thread excels in corrosion resistance and can withstand higher mechanical wear, Kevlar thread provides greater flexibility and impact resistance, crucial for protective gear and composite materials. Selecting between Kevlar and stainless steel thread depends on the specific performance requirements, where Kevlar outperforms in weight-sensitive, high-stress environments.

Composition and Material Properties

Kevlar thread is composed of aramid fibers known for their high tensile strength, lightweight nature, and excellent resistance to heat and abrasion. Stainless steel thread consists of metal alloy primarily made from iron, carbon, and chromium, offering superior corrosion resistance, durability, and conductivity. Kevlar provides flexibility and impact resistance ideal for protective gear, while stainless steel thread excels in structural applications requiring stiffness and longevity under harsh conditions.

Strength and Durability Comparison

Kevlar thread exhibits exceptional tensile strength, outperforming stainless steel thread in weight-to-strength ratio, making it ideal for applications requiring high strength with minimal weight. Its molecular structure grants superior resistance to stretching and impact, while stainless steel thread excels in rigidity and corrosion resistance but is heavier and prone to metal fatigue over time. Durability-wise, Kevlar maintains integrity under extreme conditions without rusting, whereas stainless steel threads provide robustness in harsh chemical environments but can degrade under repetitive stress.

Heat and Chemical Resistance

Kevlar thread offers superior heat resistance, maintaining structural integrity at temperatures up to 450degC, compared to stainless steel thread which can withstand even higher temperatures but is prone to oxidation at extreme heat. In terms of chemical resistance, Kevlar exhibits excellent resistance to many solvents, oils, and acids, whereas stainless steel thread resists corrosion and degradation in harsh chemical environments but can be vulnerable to certain strong acids and chlorides. Kevlar's lightweight and resilience under high-heat exposure make it ideal for applications requiring both thermal and chemical durability without the weight penalties associated with metal threads.

Flexibility and Handling

Kevlar thread offers superior flexibility compared to stainless steel thread, making it ideal for applications requiring precise handling and intricate stitching. Its lightweight and high tensile strength allow for easier manipulation without compromising durability, unlike the stiffer and heavier stainless steel thread. Kevlar's flexibility enhances comfort and efficiency in tasks where agility and maneuverability are critical.

Applications in Industry

Kevlar thread is favored in the automotive and aerospace industries due to its high tensile strength, lightweight nature, and excellent resistance to heat and corrosion, making it ideal for safety equipment, tires, and composite materials. Stainless steel thread excels in construction, marine, and heavy machinery applications where exceptional durability, resistance to rust, and structural integrity under extreme mechanical stress are required. Both threads serve critical roles, with Kevlar prioritizing weight-sensitive and high-performance environments, while stainless steel threads dominate in environments demanding longevity and robustness.

Cost Analysis: Kevlar vs Stainless Steel Thread

Kevlar thread offers a significant cost advantage over stainless steel thread due to lower raw material and manufacturing expenses, making it a budget-friendly option for high-performance applications. Despite its lighter weight and comparable tensile strength, Kevlar's resistance to corrosion reduces maintenance and replacement costs compared to stainless steel thread. The total cost of ownership for Kevlar thread is often lower, especially in industries like aerospace and automotive, where durability and cost efficiency are critical.

Wear and Corrosion Resistance

Kevlar thread exhibits exceptional wear resistance due to its high tensile strength and low abrasion susceptibility, outperforming stainless steel thread in maintaining integrity under repetitive friction. Stainless steel thread, while highly resistant to corrosion from moisture and chemicals, is prone to surface wear and fatigue over time, especially in dynamic applications. The superior corrosion resistance of stainless steel complements Kevlar's durability, but Kevlar's resilience against mechanical wear makes it preferable in environments with high friction and abrasive stress.

Safety and Environmental Impact

Kevlar thread offers superior safety due to its high tensile strength and resistance to heat, reducing the risk of breakage and failure in critical applications. Unlike stainless steel thread, Kevlar is non-corrosive and does not rust, minimizing environmental contamination and extending product lifespan. Its lightweight nature also results in lower energy consumption during manufacturing and transportation, positively impacting environmental sustainability.

Choosing the Right Thread for Your Project

Kevlar thread offers exceptional tensile strength and heat resistance, making it ideal for applications requiring lightweight durability and flexibility, such as protective gear and aerospace components. Stainless steel thread provides superior corrosion resistance and rigidity, suitable for environments exposed to moisture, chemicals, or high mechanical stress, including marine and industrial machinery. Selecting the right thread depends on factors like environmental exposure, load requirements, and flexibility needed for the specific project.

Kevlar thread vs Stainless steel thread Infographic

materialdif.com

materialdif.com