Kevlar thread offers exceptional strength and durability compared to nylon thread, making it ideal for pet products that require high resistance to wear and tear. Its heat resistance and ability to withstand extreme stress ensure that collars, harnesses, and leashes made with Kevlar thread last longer under rough conditions. Nylon thread, while flexible and cost-effective, tends to fray and weaken faster, especially when exposed to moisture and sharp claws.

Table of Comparison

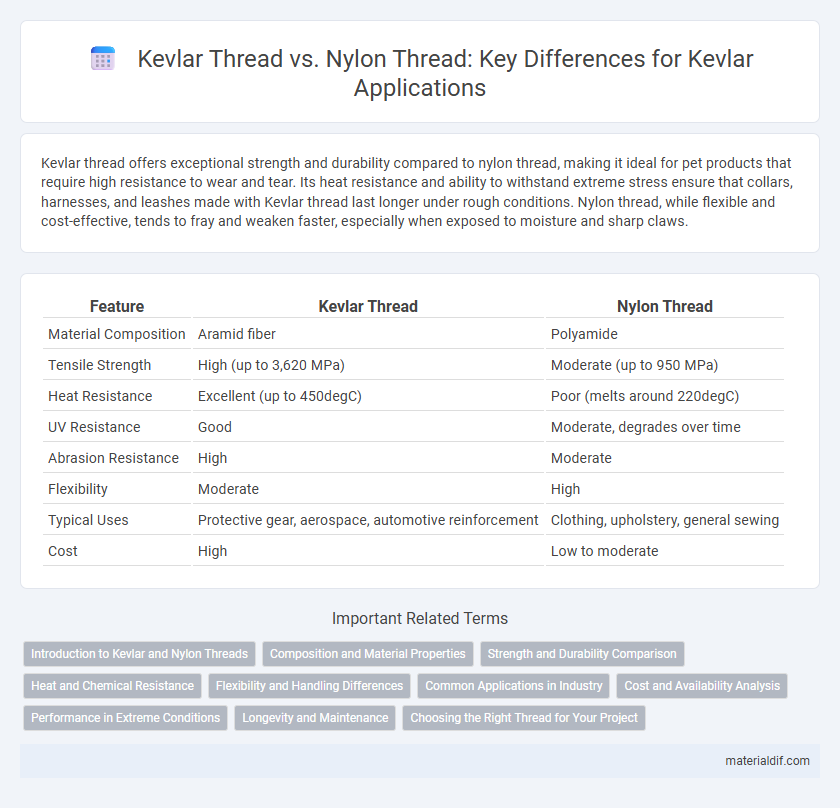

| Feature | Kevlar Thread | Nylon Thread |

|---|---|---|

| Material Composition | Aramid fiber | Polyamide |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 950 MPa) |

| Heat Resistance | Excellent (up to 450degC) | Poor (melts around 220degC) |

| UV Resistance | Good | Moderate, degrades over time |

| Abrasion Resistance | High | Moderate |

| Flexibility | Moderate | High |

| Typical Uses | Protective gear, aerospace, automotive reinforcement | Clothing, upholstery, general sewing |

| Cost | High | Low to moderate |

Introduction to Kevlar and Nylon Threads

Kevlar thread is made from aramid fibers known for exceptional strength and heat resistance, outperforming nylon thread in durability and cut resistance. Nylon thread, composed of polyamide fibers, offers high elasticity and abrasion resistance but lacks Kevlar's tensile strength and thermal stability. Both threads serve diverse applications, with Kevlar preferred in high-performance environments and nylon favored for flexible, lightweight uses.

Composition and Material Properties

Kevlar thread is composed of para-aramid synthetic fibers known for exceptional tensile strength, high heat resistance, and low elongation, making it ideal for protective applications. Nylon thread, made from polyamide polymers, offers excellent elasticity, abrasion resistance, and moderate strength but softens under high temperatures. The molecular structure of Kevlar provides superior durability and resistance to chemical degradation compared to the more flexible and water-absorbent nylon thread.

Strength and Durability Comparison

Kevlar thread offers significantly higher tensile strength than nylon thread, making it ideal for applications requiring maximum resistance to breaking or stretching. Kevlar's exceptional durability stems from its aromatic polyamide structure, which resists heat, abrasion, and chemical damage better than nylon. While nylon thread provides good flexibility and resistance to wear, Kevlar thread outperforms in high-stress environments where sustained strength and longevity are crucial.

Heat and Chemical Resistance

Kevlar thread exhibits superior heat resistance, maintaining stability up to 450degC, while nylon thread begins to degrade around 260degC. Chemically, Kevlar is highly resistant to solvents, oils, and acids, making it ideal for harsh environments where nylon threads may weaken or dissolve. This enhanced durability of Kevlar thread under extreme heat and chemical exposure outperforms nylon in industrial and safety applications.

Flexibility and Handling Differences

Kevlar thread exhibits significantly higher tensile strength and heat resistance compared to nylon thread, making it ideal for heavy-duty applications where durability is critical. While Kevlar thread is less flexible and more brittle, which can make handling and sewing more challenging, nylon thread offers superior elasticity and ease of manipulation during stitching. The rigidity of Kevlar requires specialized needles and slower sewing speeds to prevent breakage, whereas nylon's flexibility accommodates faster sewing with standard equipment.

Common Applications in Industry

Kevlar thread is extensively used in aerospace, military ballistic protection, and automotive tire reinforcement due to its exceptional strength-to-weight ratio and high resistance to heat and abrasion. Nylon thread, favored in textile manufacturing, upholstery, and consumer goods, offers elasticity and chemical resistance but lacks Kevlar's tensile strength and heat tolerance. These properties make Kevlar thread essential for heavy-duty applications requiring durability and safety, while nylon thread suits flexible, lightweight uses.

Cost and Availability Analysis

Kevlar thread typically costs significantly more than nylon thread due to its high-performance aramid fiber composition, which offers superior strength and heat resistance. Nylon thread is more widely available and affordable, making it a popular choice for general applications where extreme durability is not required. The limited production scale of Kevlar thread contributes to its higher price and occasional scarcity compared to the mass-produced nylon alternatives.

Performance in Extreme Conditions

Kevlar thread exhibits superior performance in extreme conditions due to its high tensile strength and exceptional thermal resistance, maintaining integrity in temperatures up to 450degC. Unlike nylon thread, which weakens and degrades under prolonged heat exposure and UV radiation, Kevlar thread resists chemical corrosion and abrasion, making it ideal for demanding environments. Its low elongation and high modulus ensure minimal stretch and maximum durability under intense mechanical stress.

Longevity and Maintenance

Kevlar thread outperforms nylon thread in longevity due to its superior resistance to abrasion, heat, and UV degradation, ensuring extended durability in demanding environments. Kevlar requires minimal maintenance as it retains tensile strength under stress and exposure, whereas nylon thread is prone to weakening and stretching over time, necessitating more frequent replacement. This makes Kevlar thread ideal for applications demanding long-term reliability and low upkeep.

Choosing the Right Thread for Your Project

Kevlar thread offers exceptional tensile strength and heat resistance, making it ideal for high-stress applications like protective gear or heavy-duty outdoor equipment. Nylon thread provides excellent elasticity and abrasion resistance, suitable for flexible, everyday items such as clothing or upholstery. Selecting the right thread depends on the specific project requirements, including durability, stretch, and environmental exposure.

Kevlar thread vs Nylon thread Infographic

materialdif.com

materialdif.com