Kevlar sheets provide rigid, uniform protection ideal for applications requiring high-impact resistance, while Kevlar fabric offers flexibility and breathability suited for wearable pet gear. The sheet's dense structure resists cuts and punctures more effectively, making it perfect for protective vests or armor inserts. Kevlar fabric, however, allows better movement and comfort, making it ideal for collars, harnesses, and lightweight protective clothing for pets.

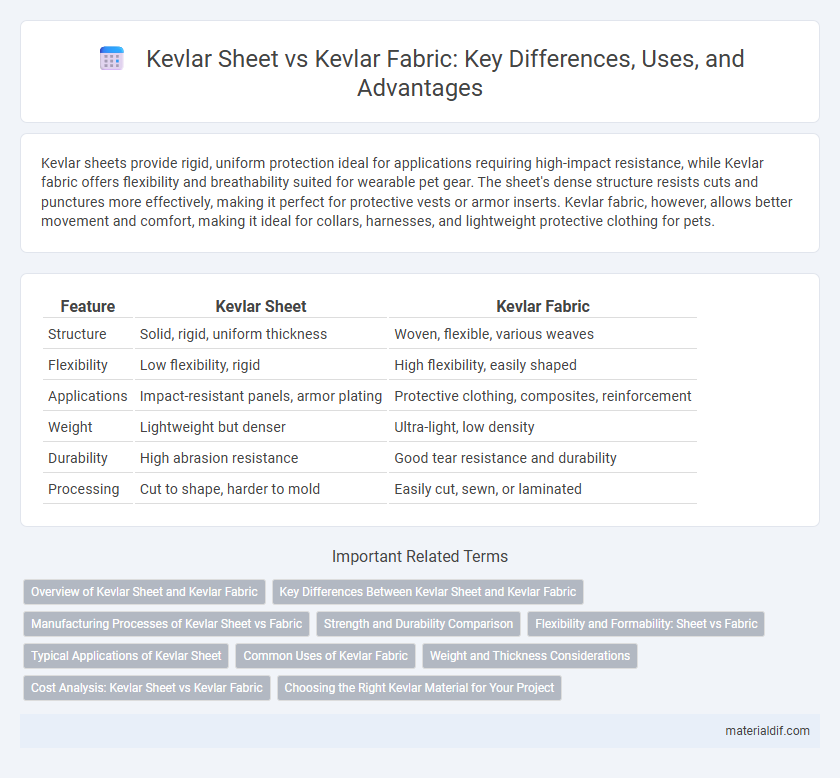

Table of Comparison

| Feature | Kevlar Sheet | Kevlar Fabric |

|---|---|---|

| Structure | Solid, rigid, uniform thickness | Woven, flexible, various weaves |

| Flexibility | Low flexibility, rigid | High flexibility, easily shaped |

| Applications | Impact-resistant panels, armor plating | Protective clothing, composites, reinforcement |

| Weight | Lightweight but denser | Ultra-light, low density |

| Durability | High abrasion resistance | Good tear resistance and durability |

| Processing | Cut to shape, harder to mold | Easily cut, sewn, or laminated |

Overview of Kevlar Sheet and Kevlar Fabric

Kevlar sheet and Kevlar fabric both utilize aramid fibers known for exceptional tensile strength and heat resistance, but differ in form and application. Kevlar sheets are rigid, pressed layers often used in ballistic armor and structural reinforcement, offering enhanced impact resistance and consistent thickness. Kevlar fabric is woven, flexible, and commonly employed in protective clothing and composite materials, allowing for customization in layering and integration with resins.

Key Differences Between Kevlar Sheet and Kevlar Fabric

Kevlar sheets consist of compressed layers of Kevlar fibers bonded together, providing rigid, impact-resistant protection ideal for armor plating and structural reinforcement. Kevlar fabric is a flexible woven material made by interlacing Kevlar yarns, offering high tensile strength and abrasion resistance for applications such as ballistic vests and protective clothing. The key difference lies in rigidity versus flexibility, with sheets suited for hard armor and fabrics for wearable, adaptable protection.

Manufacturing Processes of Kevlar Sheet vs Fabric

Kevlar sheets are manufactured through a controlled molding process where Kevlar fibers are aligned and compressed under heat and pressure to form dense, rigid panels ideal for structural applications. Kevlar fabric production involves weaving or knitting yarns spun from Kevlar fibers, resulting in flexible, lightweight textiles used in ballistic vests and protective clothing. The key manufacturing difference lies in the sheet's lamination and compression techniques versus the fabric's fiber interlacing methods, impacting durability and application scope.

Strength and Durability Comparison

Kevlar sheets exhibit superior tensile strength and enhanced impact resistance compared to Kevlar fabric due to their densely compressed and layered structure. While Kevlar fabric offers flexibility and ease of integration into various applications, Kevlar sheets provide greater durability and protection against punctures and abrasions. The choice between Kevlar sheet and fabric depends on specific strength requirements and the nature of the intended application.

Flexibility and Formability: Sheet vs Fabric

Kevlar fabric offers superior flexibility and formability compared to Kevlar sheets, allowing it to conform easily to complex shapes and contours, ideal for protective clothing and body armor applications. Kevlar sheets are more rigid and less adaptable, providing enhanced structural strength but limited ability to mold into intricate forms. The weave structure of Kevlar fabric enhances its pliability, making it preferable when flexibility is essential, whereas Kevlar sheets maintain high tensile strength for static, flat surface reinforcement.

Typical Applications of Kevlar Sheet

Kevlar sheets are widely used in applications requiring rigid and durable reinforcement, such as ballistic armor panels, structural components in aerospace, and protective casings in automotive industries. Unlike Kevlar fabric, which offers flexibility for soft body armor and clothing, Kevlar sheets provide enhanced impact resistance and stiffness essential for helmets, vehicle armor, and industrial protective barriers. Their high tensile strength and lightweight nature make them ideal for safety equipment requiring both durability and reduced weight.

Common Uses of Kevlar Fabric

Kevlar fabric is commonly used in the production of body armor, helmets, and protective clothing due to its flexibility and durability. It is preferred for applications requiring high tensile strength and impact resistance while maintaining lightweight properties. Unlike Kevlar sheets, which offer rigid protection in industrial settings, Kevlar fabric provides versatile coverage for personal and tactical gear.

Weight and Thickness Considerations

Kevlar sheets typically exhibit greater thickness and weight compared to Kevlar fabric due to their denser, compressed structure designed for rigid applications. Kevlar fabric offers superior flexibility and lighter weight, making it ideal for wearable protections and composite layering where mobility and reduced burden are crucial. Weight and thickness considerations directly impact application choices, with sheets favoring structural reinforcement and fabrics optimizing comfort and adaptability.

Cost Analysis: Kevlar Sheet vs Kevlar Fabric

Kevlar sheets typically incur higher production costs due to the intensive manufacturing process and material density compared to Kevlar fabric, which is woven and more cost-effective for large-scale applications. Kevlar fabric offers greater flexibility and ease of customization, reducing labor costs in manufacturing complex shapes, whereas sheets may require additional machining and handling. Cost analysis reveals that while Kevlar sheets provide superior structural integrity, Kevlar fabric is generally more economical for applications prioritizing lightweight and adaptable protection.

Choosing the Right Kevlar Material for Your Project

Kevlar sheets offer rigid, high-impact resistance ideal for protective panels and structural applications, while Kevlar fabric provides flexible, lightweight strength suited for wearable gear and composite layering. Selecting the right Kevlar material depends on the desired balance between stiffness and flexibility, with sheets excelling in durability and fabrics enabling contouring and breathability. Understanding project requirements for strength, weight, and form factor ensures optimal performance from Kevlar's distinct material formats.

Kevlar sheet vs Kevlar fabric Infographic

materialdif.com

materialdif.com