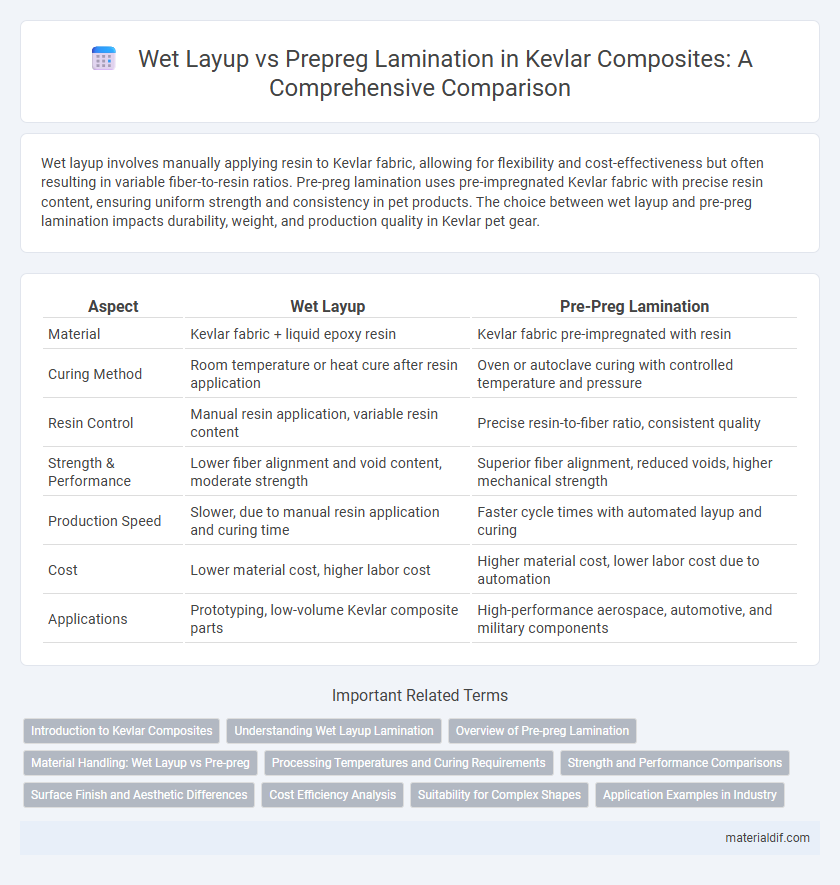

Wet layup involves manually applying resin to Kevlar fabric, allowing for flexibility and cost-effectiveness but often resulting in variable fiber-to-resin ratios. Pre-preg lamination uses pre-impregnated Kevlar fabric with precise resin content, ensuring uniform strength and consistency in pet products. The choice between wet layup and pre-preg lamination impacts durability, weight, and production quality in Kevlar pet gear.

Table of Comparison

| Aspect | Wet Layup | Pre-Preg Lamination |

|---|---|---|

| Material | Kevlar fabric + liquid epoxy resin | Kevlar fabric pre-impregnated with resin |

| Curing Method | Room temperature or heat cure after resin application | Oven or autoclave curing with controlled temperature and pressure |

| Resin Control | Manual resin application, variable resin content | Precise resin-to-fiber ratio, consistent quality |

| Strength & Performance | Lower fiber alignment and void content, moderate strength | Superior fiber alignment, reduced voids, higher mechanical strength |

| Production Speed | Slower, due to manual resin application and curing time | Faster cycle times with automated layup and curing |

| Cost | Lower material cost, higher labor cost | Higher material cost, lower labor cost due to automation |

| Applications | Prototyping, low-volume Kevlar composite parts | High-performance aerospace, automotive, and military components |

Introduction to Kevlar Composites

Kevlar composites employ two primary fabrication methods: wet layup and pre-preg lamination, each impacting composite performance and manufacturing efficiency. Wet layup involves manually saturating Kevlar fabric with resin, offering flexibility but potentially leading to inconsistent fiber-resin ratios and void content. Pre-preg lamination uses pre-impregnated Kevlar fibers with controlled resin content, optimizing fiber alignment and enhancing mechanical strength and durability in high-performance applications.

Understanding Wet Layup Lamination

Wet layup lamination involves manually saturating Kevlar fibers with resin before layering them, allowing for greater flexibility in complex shapes and lower initial costs. It requires careful control of resin-to-fiber ratios to maintain the strength and impact resistance characteristic of Kevlar composites. This method is commonly used in applications where customized or prototypical Kevlar structures are needed without the extensive equipment required for pre-preg lamination.

Overview of Pre-preg Lamination

Pre-preg lamination uses Kevlar fibers pre-impregnated with precise resin ratios, ensuring consistent fiber-to-resin distribution and superior structural integrity. This process offers enhanced mechanical properties, improved fatigue resistance, and reduced void content compared to wet layup methods. The controlled curing cycle of pre-pregs enables optimized bonding, resulting in lightweight yet highly durable Kevlar composite laminates for high-performance applications.

Material Handling: Wet Layup vs Pre-preg

Wet layup involves manually impregnating Kevlar fibers with resin, requiring precise timing and skilled handling to ensure uniform resin distribution, while pre-preg lamination uses pre-impregnated Kevlar fibers with controlled resin content stored under refrigeration to maintain material stability. Wet layup demands immediate processing after resin application due to limited working time, increasing sensitivity to environmental factors such as humidity and temperature. Pre-preg lamination offers consistent material quality and reduces variability in fiber-to-resin ratios, improving repeatability and mechanical performance in Kevlar composite manufacturing.

Processing Temperatures and Curing Requirements

Wet layup processing of Kevlar composites typically occurs at room temperature with ambient curing, requiring no specialized equipment but resulting in longer cure times and potentially lower fiber-resin adhesion. Pre-preg lamination involves Kevlar fibers pre-impregnated with resin, necessitating elevated processing temperatures usually between 120degC to 180degC and precise pressure application in an autoclave or oven to achieve optimal curing and mechanical properties. The controlled curing cycle of pre-preg lamination enhances molecular cross-linking and improves composite strength and durability compared to the more variable wet layup method.

Strength and Performance Comparisons

Wet layup Kevlar composites offer cost-effective flexibility but generally exhibit lower fiber-to-resin ratios and reduced mechanical strength compared to pre-preg lamination. Pre-preg Kevlar systems deliver superior performance with higher tensile strength, enhanced impact resistance, and consistent fiber alignment due to controlled resin content and curing processes. Strength optimization in pre-preg Kevlar laminates results in more reliable structural applications, particularly in aerospace and high-performance sporting goods.

Surface Finish and Aesthetic Differences

Wet layup with Kevlar fibers often results in a more uneven surface finish due to resin pooling and manual application inconsistencies, affecting aesthetic uniformity. Pre-preg lamination provides a smoother, high-gloss surface because the resin is pre-impregnated and uniformly distributed, minimizing air pockets and voids. The controlled curing process in pre-preg lamination enhances detailed fiber alignment and consistency, delivering superior visual quality compared to wet layup methods.

Cost Efficiency Analysis

Wet layup utilizes less expensive materials and requires lower upfront investment in equipment, making it more cost-effective for small-scale or prototype Kevlar composite production. Pre-preg lamination, although involving higher material and processing costs due to pre-impregnated fibers and autoclave curing, offers superior quality control and reduced labor, which can lower long-term expenses in high-volume manufacturing. When evaluating cost efficiency, wet layup suits limited runs with budget constraints, while pre-preg lamination excels in large-scale applications demanding consistent mechanical properties and minimized defects.

Suitability for Complex Shapes

Wet layup techniques provide significant flexibility for forming Kevlar composites around complex shapes due to the manual application of resin that adapts seamlessly to intricate contours. Pre-preg lamination offers superior consistency and fiber alignment but may face challenges conforming to highly irregular or tight-radius geometries without specialized tooling. Selecting between wet layup and pre-preg methods depends on the complexity of the Kevlar component's shape and the desired balance between precision and adaptability.

Application Examples in Industry

Wet layup of Kevlar is commonly used in marine applications such as boat hulls and canoes, where complex shapes and on-site repairs benefit from its flexibility and cost-effectiveness. Pre-preg lamination, featuring Kevlar fibers pre-impregnated with resin, is favored in aerospace and automotive industries for producing high-strength, lightweight components like aircraft panels and racing car body parts with precise fiber alignment and consistent quality. Both methods leverage Kevlar's exceptional tensile strength and impact resistance but are selected based on production volume, performance requirements, and environmental conditions.

Wet layup vs Pre-preg lamination Infographic

materialdif.com

materialdif.com