Plain weave Kevlar fabric features a simple over-under pattern, offering excellent strength and stability, making it ideal for high-impact protection. Twill weave Kevlar displays a diagonal pattern that enhances flexibility and abrasion resistance while maintaining durability. Choosing between plain and twill weave depends on the balance needed between rigidity and pliability for Kevlar pet products.

Table of Comparison

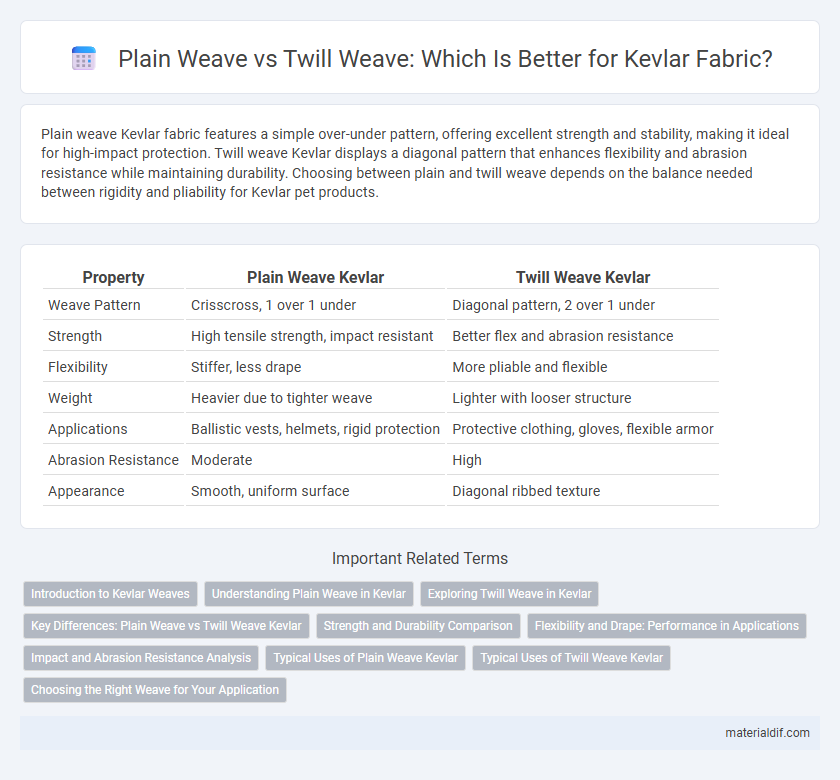

| Property | Plain Weave Kevlar | Twill Weave Kevlar |

|---|---|---|

| Weave Pattern | Crisscross, 1 over 1 under | Diagonal pattern, 2 over 1 under |

| Strength | High tensile strength, impact resistant | Better flex and abrasion resistance |

| Flexibility | Stiffer, less drape | More pliable and flexible |

| Weight | Heavier due to tighter weave | Lighter with looser structure |

| Applications | Ballistic vests, helmets, rigid protection | Protective clothing, gloves, flexible armor |

| Abrasion Resistance | Moderate | High |

| Appearance | Smooth, uniform surface | Diagonal ribbed texture |

Introduction to Kevlar Weaves

Kevlar weaves primarily include plain weave and twill weave, each offering distinct performance characteristics. Plain weave features a simple over-under pattern providing maximum fabric stability and abrasion resistance, ideal for impact protection applications. Twill weave displays a diagonal pattern that enhances flexibility and drapability, making it suitable for applications requiring conformability without sacrificing strength.

Understanding Plain Weave in Kevlar

Plain weave in Kevlar features a simple over-under interlacing pattern that provides uniform strength and stability, making it ideal for applications requiring high tensile strength and impact resistance. This weave structure ensures consistent fiber alignment and minimal distortion, enhancing Kevlar's performance in ballistic protection and composite materials. Its balanced texture also contributes to excellent dimensional stability and ease of fabrication in advanced armor systems.

Exploring Twill Weave in Kevlar

Twill weave in Kevlar features a diagonal pattern that enhances fabric drape and flexibility, making it more suitable for applications requiring superior conformability and impact resistance. This weaving technique results in higher tensile strength and better abrasion resistance compared to plain weave, due to the longer interlacing floats that distribute stress more evenly across the fibers. Twill weave Kevlar is commonly used in ballistic armor, protective clothing, and high-performance composites, where increased durability and comfort are critical.

Key Differences: Plain Weave vs Twill Weave Kevlar

Plain weave Kevlar features a simple over-under pattern that provides uniform strength and excellent abrasion resistance, making it ideal for ballistic protection and puncture resistance. Twill weave Kevlar offers a diagonal pattern that enhances flexibility and drape, allowing for better conformability and comfort in body armor applications. The key differences lie in durability versus flexibility: plain weave maximizes toughness, while twill weave improves wearability without compromising protective performance.

Strength and Durability Comparison

Kevlar's plain weave offers a tighter, more balanced fiber interlacing that enhances tensile strength and abrasion resistance, making it ideal for high-impact protection. Twill weave features a diagonal pattern allowing greater flexibility and improved drape, which enhances tear resistance but slightly reduces overall strength compared to plain weave. In applications demanding maximum durability and rigidity, plain weave Kevlar outperforms twill, while twill is preferred for scenarios requiring a compromise between strength and flexibility.

Flexibility and Drape: Performance in Applications

Kevlar plain weave features a tight, crisscross pattern that offers exceptional strength and stability but limited flexibility and drape, making it ideal for applications requiring rigid protection like bulletproof vests. Twill weave Kevlar, characterized by its diagonal rib pattern, provides enhanced flexibility and better drape, improving comfort and conformity in body armor and sporting equipment. The choice between plain and twill weave Kevlar depends on balancing structural rigidity with the need for ergonomic performance in specific applications.

Impact and Abrasion Resistance Analysis

Plain weave Kevlar fabric offers superior impact resistance due to its tight, uniform interlacing pattern that evenly distributes force across the material. Twill weave Kevlar provides enhanced abrasion resistance through its diagonal rib pattern, which allows greater flexibility and surface area contact, reducing wear in dynamic environments. Comparative testing reveals that plain weave excels in puncture and blunt force scenarios, while twill weave outperforms in resisting surface friction and repetitive stress.

Typical Uses of Plain Weave Kevlar

Plain weave Kevlar is commonly used in ballistic protection such as bulletproof vests and helmets due to its balanced yarn structure that provides excellent tensile strength and stab resistance. The tight, over-under pattern enhances durability and impacts dispersion, making it ideal for body armor and protective gear in law enforcement and military applications. Its uniform surface also supports composite materials in aerospace and automotive industries where lightweight, high-strength fabrics are essential.

Typical Uses of Twill Weave Kevlar

Twill weave Kevlar features a diagonal pattern that offers enhanced drapability and flexibility compared to the tighter, more rigid plain weave. This makes twill weave Kevlar ideal for applications requiring high contour conformity and comfort, such as ballistic body armor, protective gloves, and motorcycle apparel. The superior flexibility also improves performance in composite materials used in aerospace and automotive industries.

Choosing the Right Weave for Your Application

Plain weave Kevlar features a simple over-under pattern that maximizes tensile strength and wear resistance, making it ideal for ballistic protection and cut-resistant gear. Twill weave Kevlar offers greater flexibility and drape due to its diagonal pattern, enhancing comfort and contouring in lightweight body armor and sporting equipment. Selecting the right weave depends on balancing strength requirements with flexibility needs specific to applications such as helmets, gloves, or vehicle armor.

Plain Weave vs Twill Weave (Kevlar) Infographic

materialdif.com

materialdif.com