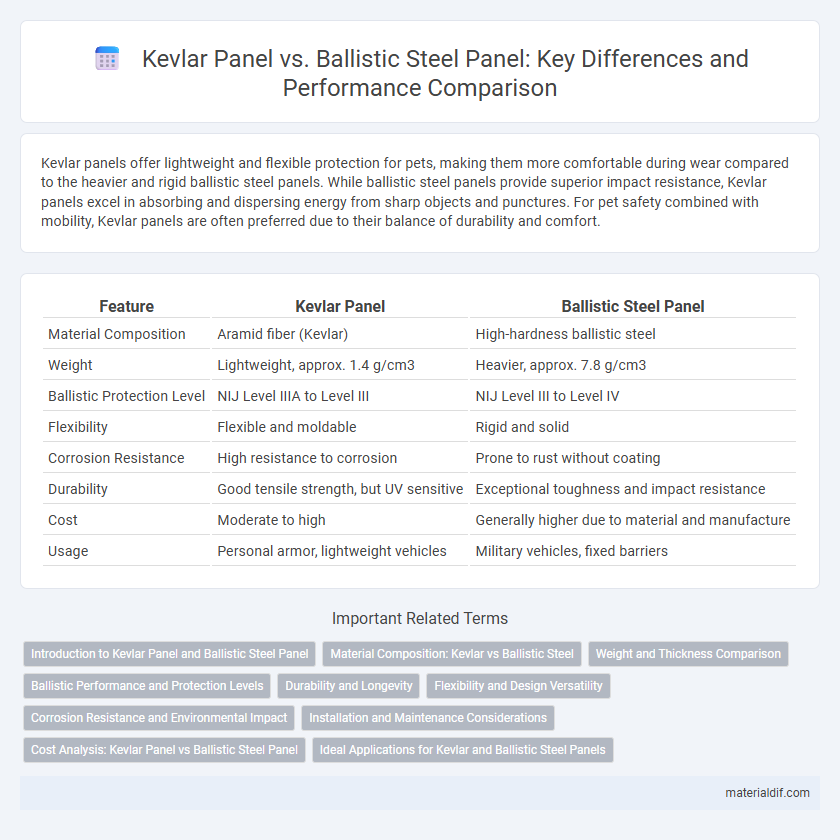

Kevlar panels offer lightweight and flexible protection for pets, making them more comfortable during wear compared to the heavier and rigid ballistic steel panels. While ballistic steel panels provide superior impact resistance, Kevlar panels excel in absorbing and dispersing energy from sharp objects and punctures. For pet safety combined with mobility, Kevlar panels are often preferred due to their balance of durability and comfort.

Table of Comparison

| Feature | Kevlar Panel | Ballistic Steel Panel |

|---|---|---|

| Material Composition | Aramid fiber (Kevlar) | High-hardness ballistic steel |

| Weight | Lightweight, approx. 1.4 g/cm3 | Heavier, approx. 7.8 g/cm3 |

| Ballistic Protection Level | NIJ Level IIIA to Level III | NIJ Level III to Level IV |

| Flexibility | Flexible and moldable | Rigid and solid |

| Corrosion Resistance | High resistance to corrosion | Prone to rust without coating |

| Durability | Good tensile strength, but UV sensitive | Exceptional toughness and impact resistance |

| Cost | Moderate to high | Generally higher due to material and manufacture |

| Usage | Personal armor, lightweight vehicles | Military vehicles, fixed barriers |

Introduction to Kevlar Panel and Ballistic Steel Panel

Kevlar panels are lightweight, flexible composite materials made from para-aramid fibers known for high tensile strength and impact resistance, commonly used in personal armor and vehicle protection. Ballistic steel panels, composed of hardened steel alloys, offer superior rigidity and penetration resistance but are significantly heavier than Kevlar panels. The choice between Kevlar and ballistic steel panels depends on the balance of weight, protection level, and application-specific requirements such as mobility and durability.

Material Composition: Kevlar vs Ballistic Steel

Kevlar panels consist of ultra-high-molecular-weight polyethylene fibers woven into a lightweight, flexible fabric that offers high tensile strength and excellent energy absorption, making them highly effective for ballistic protection. In contrast, ballistic steel panels are composed of hardened steel alloys, providing superior rigidity and impact resistance but with significantly increased weight and reduced flexibility. The difference in material composition results in Kevlar panels being preferred for applications prioritizing weight and mobility, while ballistic steel panels are chosen for scenarios demanding maximum durability and blunt force resistance.

Weight and Thickness Comparison

Kevlar panels offer a significant advantage in weight, being up to 40% lighter than ballistic steel panels while maintaining high ballistic protection levels. Their thickness is also notably less, typically around 6-8 mm compared to 12-15 mm for steel, enhancing maneuverability and comfort in protective gear. This reduced weight and thickness make Kevlar panels ideal for applications where mobility and rapid response are critical.

Ballistic Performance and Protection Levels

Kevlar panels provide superior ballistic performance by effectively dissipating the energy of high-velocity projectiles through their layered aramid fibers, offering enhanced protection against handgun and rifle rounds. Ballistic steel panels, while heavier, deliver higher resistance to penetration and are especially effective against armor-piercing rounds and repeated impacts due to their rigid structure. The protection levels of Kevlar panels are optimized for lightweight, flexible applications, whereas ballistic steel panels offer maximum protection in scenarios requiring robust, durable armor solutions.

Durability and Longevity

Kevlar panels exhibit superior durability compared to ballistic steel panels due to their high tensile strength and resistance to impact fatigue, ensuring prolonged performance under repeated stress. Kevlar's lightweight, flexible composition reduces the risk of material degradation over time, maintaining structural integrity in harsh environments. In contrast, ballistic steel panels are prone to corrosion and require regular maintenance to preserve longevity, making Kevlar a more sustainable choice for long-term ballistic protection.

Flexibility and Design Versatility

Kevlar panels offer superior flexibility compared to ballistic steel panels, allowing for easier contouring to various shapes and applications. Their lightweight nature enhances design versatility, enabling integration into complex structures without compromising mobility or comfort. Kevlar's adaptability in layering and thickness provides customized protection levels, surpassing the rigidity and weight constraints of ballistic steel panels.

Corrosion Resistance and Environmental Impact

Kevlar panels demonstrate superior corrosion resistance compared to ballistic steel panels, as Kevlar fibers are inherently non-metallic and do not oxidize or rust when exposed to moisture and chemicals. This corrosion resistance reduces maintenance needs and extends the lifespan of Kevlar armor in harsh environmental conditions. Environmentally, Kevlar panels have a lower ecological impact due to reduced metal mining and processing energy demands, alongside better recyclability compared to the heavy metal content of ballistic steel.

Installation and Maintenance Considerations

Kevlar panels offer lightweight installation benefits compared to ballistic steel panels, reducing labor time and structural support requirements in armor systems. Maintenance of Kevlar panels involves regular inspections for fiber integrity and moisture damage, while ballistic steel panels require rust prevention and surface treatment to maintain effectiveness. Kevlar's flexibility allows easier customization during installation, whereas steel panels demand specialized tools and handling due to their weight and rigidity.

Cost Analysis: Kevlar Panel vs Ballistic Steel Panel

Kevlar panels typically offer a cost advantage over ballistic steel panels due to lower material and manufacturing expenses, making them more economically viable for large-scale production. Although ballistic steel panels provide superior hardness and multi-hit capability, their higher weight and processing costs contribute to increased overall expenditure. The cost-effectiveness of Kevlar panels is enhanced by their corrosion resistance and ease of integration into lightweight protective systems, reducing long-term maintenance costs compared to ballistic steel alternatives.

Ideal Applications for Kevlar and Ballistic Steel Panels

Kevlar panels provide exceptional lightweight ballistic protection, making them ideal for applications requiring high mobility such as body armor, helmets, and vehicle reinforcements where weight reduction is critical. Ballistic steel panels offer superior durability and multi-hit resistance, suited for fixed structures like military vehicles, checkpoints, and architectural security barriers that demand robust, long-lasting defense. Choosing between Kevlar and ballistic steel depends on balancing weight efficiency against maximum protection in environments ranging from personal defense to heavy-duty military operations.

Kevlar panel vs Ballistic steel panel Infographic

materialdif.com

materialdif.com