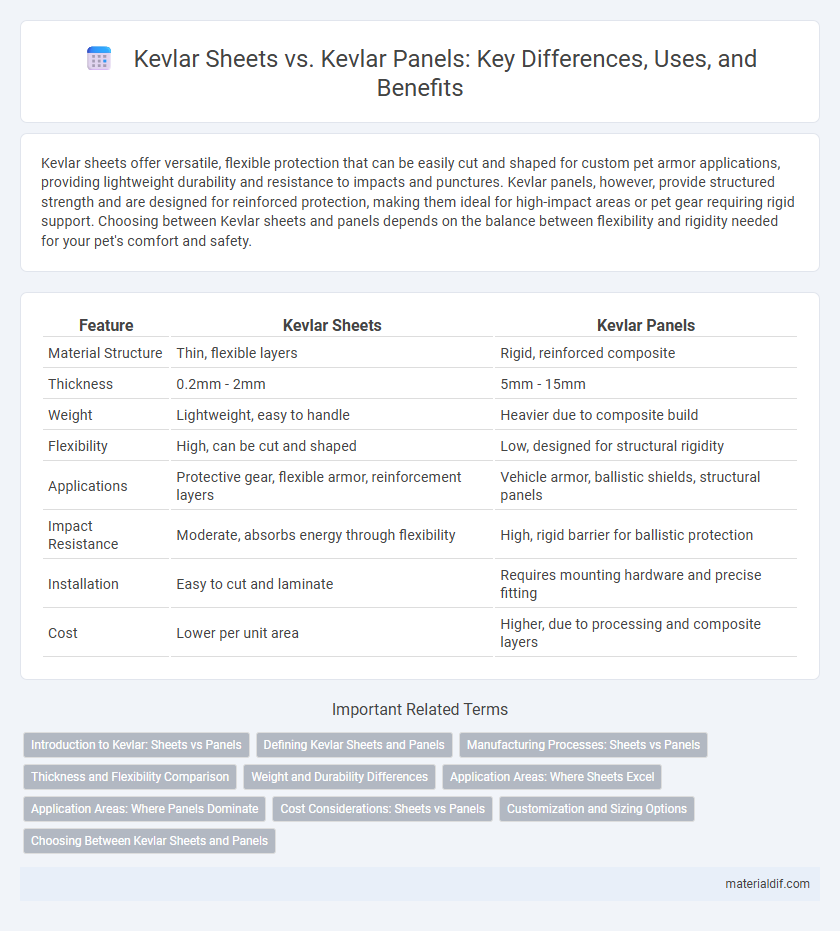

Kevlar sheets offer versatile, flexible protection that can be easily cut and shaped for custom pet armor applications, providing lightweight durability and resistance to impacts and punctures. Kevlar panels, however, provide structured strength and are designed for reinforced protection, making them ideal for high-impact areas or pet gear requiring rigid support. Choosing between Kevlar sheets and panels depends on the balance between flexibility and rigidity needed for your pet's comfort and safety.

Table of Comparison

| Feature | Kevlar Sheets | Kevlar Panels |

|---|---|---|

| Material Structure | Thin, flexible layers | Rigid, reinforced composite |

| Thickness | 0.2mm - 2mm | 5mm - 15mm |

| Weight | Lightweight, easy to handle | Heavier due to composite build |

| Flexibility | High, can be cut and shaped | Low, designed for structural rigidity |

| Applications | Protective gear, flexible armor, reinforcement layers | Vehicle armor, ballistic shields, structural panels |

| Impact Resistance | Moderate, absorbs energy through flexibility | High, rigid barrier for ballistic protection |

| Installation | Easy to cut and laminate | Requires mounting hardware and precise fitting |

| Cost | Lower per unit area | Higher, due to processing and composite layers |

Introduction to Kevlar: Sheets vs Panels

Kevlar sheets are thin, flexible layers primarily used for lightweight applications requiring high tensile strength and cut resistance, commonly found in protective clothing and composite materials. Kevlar panels, composed of multiple laminated sheets, provide enhanced structural integrity and impact resistance, making them ideal for ballistic armor, vehicle armor, and industrial shielding. Both forms leverage Kevlar's exceptional durability and heat resistance but differ in thickness and use cases based on performance demands.

Defining Kevlar Sheets and Panels

Kevlar sheets are thin, flexible layers composed of woven aramid fibers designed for lightweight protection and easy customization. Kevlar panels consist of laminated or bonded sheets, creating rigid, structurally enhanced units used in ballistic armor and industrial applications. Both forms leverage Kevlar's high tensile strength and impact resistance while differing in rigidity and application versatility.

Manufacturing Processes: Sheets vs Panels

Kevlar sheets are typically manufactured using continuous weaving techniques that create thin, flexible layers ideal for diverse applications requiring lightweight armor or reinforcement. Kevlar panels, on the other hand, involve laminating multiple sheets or layers under high heat and pressure to form rigid, thicker structures designed for enhanced ballistic protection and structural integrity. The manufacturing process for panels incorporates resin infusion or compression molding, resulting in composite materials optimized for helmets, vehicle armor, and protective barriers.

Thickness and Flexibility Comparison

Kevlar sheets typically offer greater flexibility due to their thinner profiles, generally ranging from 0.1 to 0.5 millimeters, making them ideal for applications requiring contouring and lightweight protection. Kevlar panels are thicker, often between 2 to 10 millimeters, providing enhanced structural strength and ballistic resistance but reduced flexibility. The thickness disparity directly impacts the material's adaptability, with sheets better suited for layered or composite integration, while panels serve as robust standalone armor solutions.

Weight and Durability Differences

Kevlar sheets are thinner and lighter, offering flexible protection ideal for applications where weight reduction is critical, while Kevlar panels are thicker, providing enhanced durability and impact resistance for high-strength structural needs. The weight difference between sheets and panels significantly affects their use in industries like aerospace and automotive, where lightweight materials reduce fuel consumption and improve performance. Durability in Kevlar panels is superior due to their layered composition, making them more suitable for heavy-duty protective gear and ballistic armor.

Application Areas: Where Sheets Excel

Kevlar sheets excel in applications requiring flexible, lightweight, and customizable protection such as body armor, helmets, and automotive parts due to their ability to be easily cut and shaped. Unlike Kevlar panels, which offer rigid structural support for aerospace and construction, sheets provide superior adaptability for wearable and impact-resistant gear. Their seamless integration into textile composites enhances ballistic protection and abrasion resistance in personal protective equipment.

Application Areas: Where Panels Dominate

Kevlar panels excel in structural reinforcement applications such as aerospace, automotive, and ballistic protection due to their pre-fabricated, rigid form that ensures consistent strength and ease of installation. In contrast, Kevlar sheets offer flexibility suited for textile and composite layups but lack the dimensional stability needed for load-bearing uses. Industries demanding high-impact resistance and uniform stress distribution prefer Kevlar panels for reliable performance and durability.

Cost Considerations: Sheets vs Panels

Kevlar sheets generally offer a more cost-effective solution for projects requiring flexible, customizable sizing compared to Kevlar panels, which are pre-fabricated and often come at a higher price due to added processing and reinforcement. Panels tend to have integrated features such as multiple layers or specific bonding techniques, increasing overall expenses but enhancing durability and structural integrity. For budget-sensitive applications demanding tailored shapes or lightweight protection, Kevlar sheets present a more economical choice, while panels suit scenarios prioritizing strength and ready-to-use form.

Customization and Sizing Options

Kevlar sheets offer greater customization and flexible sizing options, allowing precise cuts to meet specific design requirements in applications such as aerospace and protective gear. Kevlar panels typically come in pre-defined sizes and thicknesses, providing standardized dimensions for quick installation and consistent performance. The choice between sheets and panels depends on whether a project requires tailored fits or ready-to-use components for efficient deployment.

Choosing Between Kevlar Sheets and Panels

Kevlar sheets offer flexibility and can be easily cut to customize protection, making them ideal for applications requiring intricate shapes and tailored armor. Kevlar panels, pre-assembled and thicker, provide enhanced impact resistance and consistent protection, suitable for heavy-duty ballistic gear. Selecting between Kevlar sheets and panels depends on the balance between desired mobility, coverage area, and the level of ballistic threat protection needed.

Kevlar sheets vs Kevlar panels Infographic

materialdif.com

materialdif.com