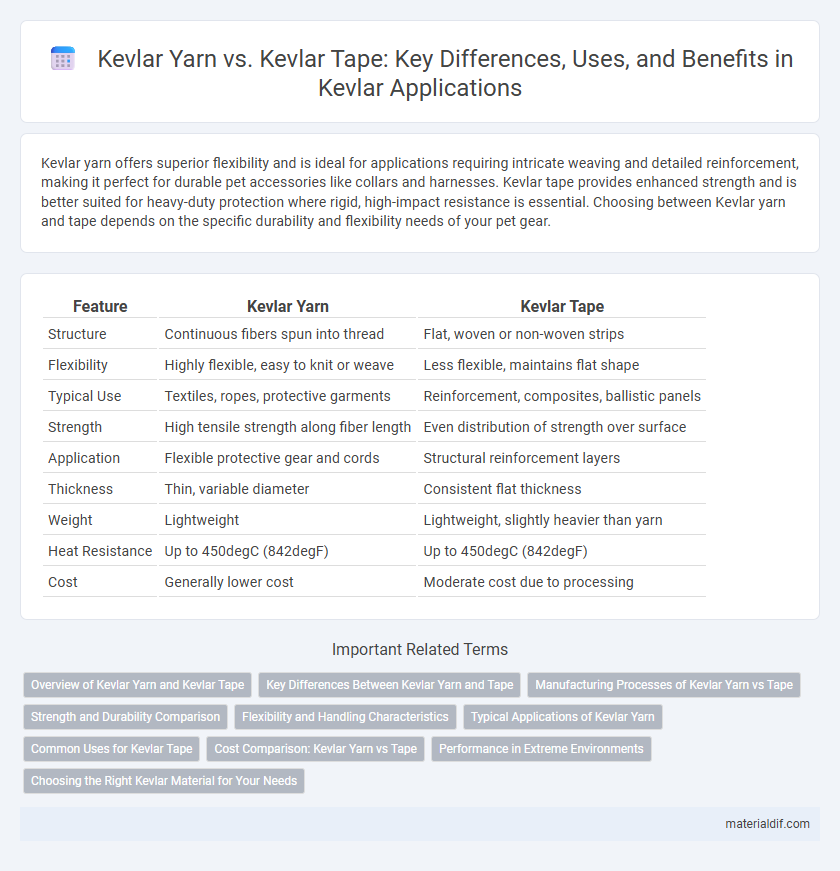

Kevlar yarn offers superior flexibility and is ideal for applications requiring intricate weaving and detailed reinforcement, making it perfect for durable pet accessories like collars and harnesses. Kevlar tape provides enhanced strength and is better suited for heavy-duty protection where rigid, high-impact resistance is essential. Choosing between Kevlar yarn and tape depends on the specific durability and flexibility needs of your pet gear.

Table of Comparison

| Feature | Kevlar Yarn | Kevlar Tape |

|---|---|---|

| Structure | Continuous fibers spun into thread | Flat, woven or non-woven strips |

| Flexibility | Highly flexible, easy to knit or weave | Less flexible, maintains flat shape |

| Typical Use | Textiles, ropes, protective garments | Reinforcement, composites, ballistic panels |

| Strength | High tensile strength along fiber length | Even distribution of strength over surface |

| Application | Flexible protective gear and cords | Structural reinforcement layers |

| Thickness | Thin, variable diameter | Consistent flat thickness |

| Weight | Lightweight | Lightweight, slightly heavier than yarn |

| Heat Resistance | Up to 450degC (842degF) | Up to 450degC (842degF) |

| Cost | Generally lower cost | Moderate cost due to processing |

Overview of Kevlar Yarn and Kevlar Tape

Kevlar yarn is composed of strong, continuous filaments ideal for weaving into fabrics and creating flexible, lightweight reinforcement in composites. Kevlar tape consists of flat, narrow strips made from woven or bundled Kevlar fibers, offering enhanced tensile strength and stability for applications like ballistic protection and structural reinforcement. Both forms leverage Kevlar's exceptional tensile strength, heat resistance, and durability, with yarn being preferred for textile uses and tape for rigid, load-bearing components.

Key Differences Between Kevlar Yarn and Tape

Kevlar yarn consists of continuous fibers spun into threads, offering excellent tensile strength and flexibility ideal for weaving and knitting applications. Kevlar tape is a flat, ribbon-like form designed for reinforcement and lamination, providing higher surface area for bonding but less pliability than yarn. The choice between Kevlar yarn and tape depends on the required mechanical properties and application, with yarn favored for flexibility and tape preferred for structural reinforcement.

Manufacturing Processes of Kevlar Yarn vs Tape

Kevlar yarn is produced through a spinning process where liquid crystal polymer solution is extruded and solidified into continuous filaments, which are then twisted into yarn strands to enhance tensile strength. Kevlar tape manufacturing involves weaving or knitting these yarns into flat, narrow strips that provide uniform thickness and flexibility, suitable for composite reinforcement applications. The yarn spinning process prioritizes fiber strength and length control, whereas tape production emphasizes dimensional stability and surface uniformity for lamination and bonding purposes.

Strength and Durability Comparison

Kevlar yarn offers exceptional tensile strength due to its continuous filaments, making it ideal for applications requiring flexibility and high resistance to stretching. Kevlar tape, composed of woven or laminated fibers, provides enhanced durability and abrasion resistance, suitable for structural reinforcements and protective layering. Strength tests reveal Kevlar yarn exhibits higher elongation before breaking, while Kevlar tape maintains superior integrity under repetitive stress and wear conditions.

Flexibility and Handling Characteristics

Kevlar yarn offers superior flexibility and ease of handling due to its twisted fiber structure, making it ideal for applications requiring intricate weaving or tight bends. In contrast, Kevlar tape provides enhanced dimensional stability and flatness, which improves load distribution but reduces pliability during manipulation. Choosing between Kevlar yarn and tape depends on the specific flexibility demands and handling requirements of the intended use.

Typical Applications of Kevlar Yarn

Kevlar yarn is commonly used in applications requiring high tensile strength and flexibility, such as ballistic protection, ropes, cables, and composite reinforcements in aerospace and automotive industries. Its ability to be woven into fabrics allows for lightweight, durable materials ideal for body armor, sports equipment, and industrial gloves. Unlike Kevlar tape, which is primarily used for structural reinforcement and layering, Kevlar yarn provides versatility in textile-based applications where flexibility and strength are crucial.

Common Uses for Kevlar Tape

Kevlar tape is commonly used in applications requiring high tensile strength and flexibility, such as reinforcing composites in aerospace and automotive industries. It is favored for protective gear manufacturing, including cut-resistant gloves and body armor, due to its durability and lightweight properties. Unlike Kevlar yarn, Kevlar tape provides better structural stability and is easier to handle in layering and lamination processes.

Cost Comparison: Kevlar Yarn vs Tape

Kevlar yarn typically offers a lower cost per unit length compared to Kevlar tape, making it more economical for bulk applications where flexibility and strength are required. Kevlar tape, while more expensive, provides enhanced dimensional stability and easier handling in precision manufacturing processes, justifying its higher price in specialized uses. Cost efficiency depends on the specific application requirements, with yarn favored in large-scale, cost-sensitive projects and tape preferred for technical, high-performance uses.

Performance in Extreme Environments

Kevlar yarn offers superior flexibility and tensile strength, allowing it to conform easily to complex shapes in extreme environments while maintaining durability under intense heat and pressure. Kevlar tape provides enhanced abrasion resistance and dimensional stability, making it ideal for applications requiring consistent thickness and impact resistance in harsh conditions. Both materials perform exceptionally in high-temperature, high-stress situations, but the choice depends on whether flexibility or structural rigidity is prioritized.

Choosing the Right Kevlar Material for Your Needs

Kevlar yarn offers superior flexibility and tensile strength, making it ideal for applications requiring intricate weaving or high-impact resistance, such as ballistic fabrics and composite reinforcements. Kevlar tape, characterized by its flat, ribbon-like structure, provides better stability and dimensional control, which suits it for use in structural components or layered laminates. Selecting between Kevlar yarn and tape depends on the balance between flexibility, strength, and the specific performance requirements of the project.

Kevlar Yarn vs Kevlar Tape Infographic

materialdif.com

materialdif.com