Kevlar fabric offers high durability and resistance to abrasion, making it ideal for pet harnesses and protective gear that require flexibility and strength. Kevlar string, while still strong, is thinner and better suited for applications like pet leash stitching or lightweight reinforcement. Choosing between Kevlar fabric and Kevlar string depends on whether maximum protection or lightweight flexibility is the priority for your pet's comfort and safety.

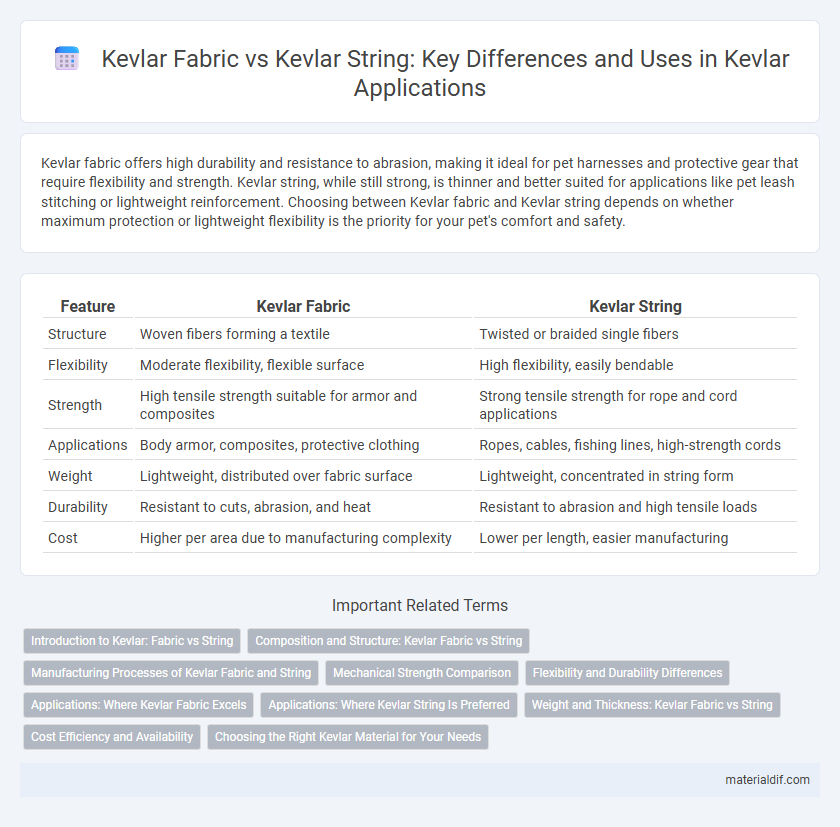

Table of Comparison

| Feature | Kevlar Fabric | Kevlar String |

|---|---|---|

| Structure | Woven fibers forming a textile | Twisted or braided single fibers |

| Flexibility | Moderate flexibility, flexible surface | High flexibility, easily bendable |

| Strength | High tensile strength suitable for armor and composites | Strong tensile strength for rope and cord applications |

| Applications | Body armor, composites, protective clothing | Ropes, cables, fishing lines, high-strength cords |

| Weight | Lightweight, distributed over fabric surface | Lightweight, concentrated in string form |

| Durability | Resistant to cuts, abrasion, and heat | Resistant to abrasion and high tensile loads |

| Cost | Higher per area due to manufacturing complexity | Lower per length, easier manufacturing |

Introduction to Kevlar: Fabric vs String

Kevlar fabric is a woven textile made from high-strength aramid fibers, offering durability and flexibility for protective gear, ballistic armor, and industrial applications. Kevlar string, on the other hand, consists of thinner, braided fibers used primarily in specialized gear like fishing lines, parachute cords, and high-strength sewing threads. Both forms leverage Kevlar's exceptional tensile strength and heat resistance, but fabric provides broader coverage while string excels in precision and lightweight strength.

Composition and Structure: Kevlar Fabric vs String

Kevlar fabric consists of interwoven aramid fibers forming a flexible, durable textile with high tensile strength and resistance to abrasion, ideal for protective clothing and body armor. Kevlar string, on the other hand, is made of tightly twisted or braided Kevlar filaments, providing superior strength in a narrow, linear form suitable for ropes, cords, and high-stress applications. The fabric's woven structure distributes impact forces over a wider area, while the string's composition offers concentrated tensile strength along its length.

Manufacturing Processes of Kevlar Fabric and String

Kevlar fabric is manufactured through a complex weaving process where aramid fibers are spun into yarn and then woven into tightly woven sheets, providing high tensile strength and flexibility. Kevlar string, in contrast, is produced by directly spinning the aramid fibers into continuous filaments or multifilament yarns without weaving, resulting in a thinner and more lightweight product ideal for applications requiring precision and minimal bulk. The distinction in manufacturing processes impacts the mechanical properties and end-use applications, with fabric offering enhanced abrasion resistance and string delivering superior tensile strength-to-weight ratios.

Mechanical Strength Comparison

Kevlar fabric exhibits superior tensile strength and impact resistance compared to Kevlar string due to its woven structure that distributes load evenly across fibers. The interlaced design in Kevlar fabric enhances durability and resistance to tearing, making it ideal for body armor and protective gear. In contrast, Kevlar string, while strong in individual fiber strength, lacks the mechanical reinforcement found in fabric, resulting in lower overall load-bearing capacity.

Flexibility and Durability Differences

Kevlar fabric offers superior flexibility due to its woven structure, allowing it to bend and conform to shapes without compromising strength. Kevlar string, while highly durable and tensile, is less flexible as it is composed of tightly twisted fibers designed for tensile stress rather than bending. The durability of Kevlar fabric excels in impact resistance and abrasion, whereas Kevlar string provides exceptional strength in tensile applications but can be more prone to fraying under repetitive bending.

Applications: Where Kevlar Fabric Excels

Kevlar fabric excels in applications requiring high tensile strength and durability, such as body armor, protective clothing, and industrial reinforcement. Its woven structure provides superior resistance to abrasion, cutting, and impact compared to Kevlar string, making it ideal for bulletproof vests and motorcycle gear. Applications in aerospace and automotive industries also benefit from Kevlar fabric's lightweight yet robust composition, enhancing safety without compromising mobility.

Applications: Where Kevlar String Is Preferred

Kevlar string is preferred in applications requiring high tensile strength with flexibility, such as in fishing lines, archery bowstrings, and musical instrument strings. Its lightweight and abrasion-resistant properties make it ideal for uses where durability and minimal stretch are critical. Kevlar fabric, while excellent for protective clothing and body armor, lacks the fine, pliable characteristics necessary for string applications.

Weight and Thickness: Kevlar Fabric vs String

Kevlar fabric offers a balanced combination of lightweight properties and consistent thickness, making it ideal for protective gear requiring flexibility and durability. In contrast, Kevlar string is significantly thinner and lighter, designed for high tensile strength applications such as ropes and fishing lines where minimal weight is crucial. The fabric's woven structure increases thickness and weight slightly but provides enhanced impact resistance, whereas the string prioritizes reduced diameter for ease of use in precision tasks.

Cost Efficiency and Availability

Kevlar fabric offers higher cost efficiency due to its widespread availability and bulk manufacturing processes, making it suitable for large-scale applications like protective gear and composites. Kevlar string, while more expensive per unit length, provides precise tensile strength for specialized uses such as fishing lines or surgical sutures. Availability of Kevlar fabric exceeds that of Kevlar string, resulting in better market accessibility and lower procurement costs for industrial consumers.

Choosing the Right Kevlar Material for Your Needs

Kevlar fabric offers enhanced durability and abrasion resistance, making it ideal for protective clothing, body armor, and industrial applications requiring broad coverage. Kevlar string provides exceptional tensile strength and flexibility, suited for high-strength ropes, fishing lines, and composite reinforcement in precision tasks. Selecting the right Kevlar material depends on whether your project prioritizes surface protection and flexibility (fabric) or high tensile strength with minimal stretch (string).

Kevlar Fabric vs Kevlar String Infographic

materialdif.com

materialdif.com