Kevlar filament offers continuous, high-strength fibers ideal for durable, abrasion-resistant pet products like leashes and harnesses, providing superior tensile strength and longevity. Kevlar staple consists of shorter fibers, making it better suited for flexible, padded pet gear that requires softness and resilience without sacrificing protection. Choosing between Kevlar filament and staple depends on the specific pet product's needs for durability versus comfort.

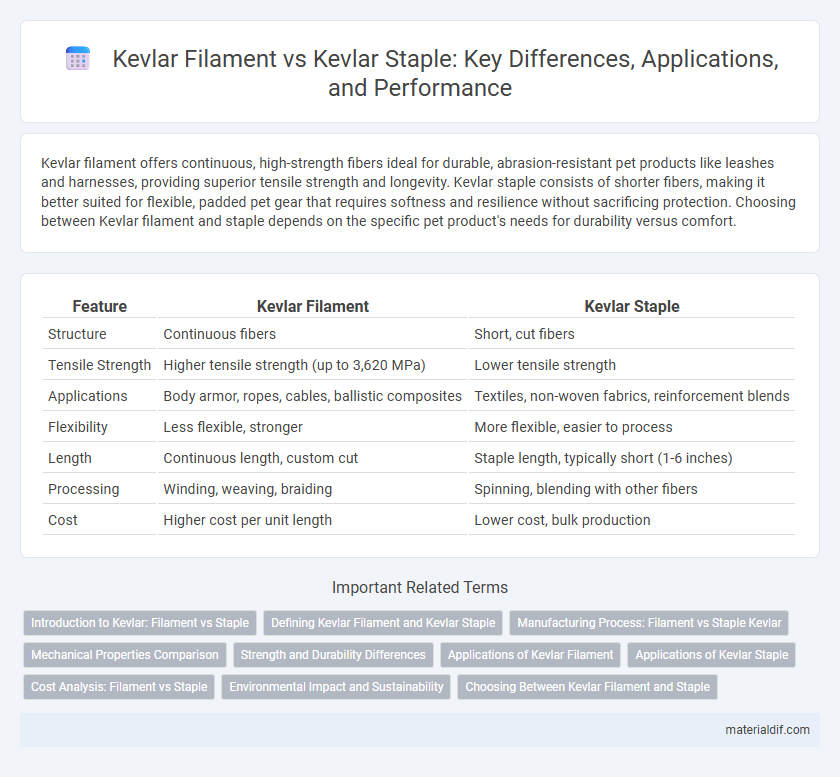

Table of Comparison

| Feature | Kevlar Filament | Kevlar Staple |

|---|---|---|

| Structure | Continuous fibers | Short, cut fibers |

| Tensile Strength | Higher tensile strength (up to 3,620 MPa) | Lower tensile strength |

| Applications | Body armor, ropes, cables, ballistic composites | Textiles, non-woven fabrics, reinforcement blends |

| Flexibility | Less flexible, stronger | More flexible, easier to process |

| Length | Continuous length, custom cut | Staple length, typically short (1-6 inches) |

| Processing | Winding, weaving, braiding | Spinning, blending with other fibers |

| Cost | Higher cost per unit length | Lower cost, bulk production |

Introduction to Kevlar: Filament vs Staple

Kevlar filament consists of continuous, long fibers that provide superior tensile strength and uniformity, making it ideal for high-performance applications such as ballistic protection and aerospace components. Kevlar staple fibers are short, chopped strands commonly used in textile blends and composites, offering flexibility and ease of processing for diverse manufacturing needs. Understanding the distinction between Kevlar filament and staple fibers is crucial for selecting the appropriate form based on durability, strength, and end-use requirements.

Defining Kevlar Filament and Kevlar Staple

Kevlar filament consists of continuous, long fibers that provide superior tensile strength and are used in applications requiring high-performance durability, such as ballistic protection and aerospace composites. Kevlar staple fibers are short, cut fibers typically used in blended textiles and nonwoven materials, offering flexibility and ease of processing. The choice between Kevlar filament and staple depends on the desired balance of strength, elasticity, and manufacturability in industrial or protective products.

Manufacturing Process: Filament vs Staple Kevlar

Kevlar filament production involves spinning continuous fibers through a wet-spinning process that aligns polymer chains for high tensile strength, while staple Kevlar consists of cutting these continuous fibers into shorter lengths mimicking natural fibers. The filament manufacturing process ensures uniformity and superior mechanical properties suitable for ballistic applications, whereas staple Kevlar is easier to blend with other fibers for textile manufacturing. Differences in processing influence end-use performance, with filament Kevlar preferred for advanced composites and staple Kevlar utilized in protective clothing and industrial materials.

Mechanical Properties Comparison

Kevlar filament exhibits superior tensile strength and higher modulus compared to Kevlar staple, making it ideal for applications requiring maximum durability and load-bearing capacity. Kevlar staple fibers, consisting of shorter, chopped fibers, offer increased flexibility and better conformability but lower mechanical strength and impact resistance. The filament form maintains continuous fiber alignment that enhances elongation resistance and fatigue performance essential for ballistic and aerospace materials.

Strength and Durability Differences

Kevlar filament offers superior tensile strength and uniformity compared to Kevlar staple fibers, making it ideal for high-performance applications requiring maximum durability. The continuous nature of Kevlar filament enhances resistance to abrasion and impact, providing consistent load-bearing capability. Kevlar staple fibers, while slightly less strong, offer greater flexibility and ease of weaving, balancing durability with adaptability in textile manufacturing.

Applications of Kevlar Filament

Kevlar filament is extensively utilized in high-performance applications such as ballistic protection, aerospace components, and automotive reinforcement, where continuous fiber strength and durability are crucial. Kevlar filament's superior tensile strength and lightweight characteristics make it ideal for composite materials in helmets, body armor, and light structural parts. In contrast to Kevlar staple fibers, filament forms provide enhanced load-bearing capacity and resistance to impact in advanced protective gear and industrial uses.

Applications of Kevlar Staple

Kevlar staple fibers are commonly utilized in protective clothing, automotive components, and composite reinforcements due to their excellent abrasion resistance and flexibility. Their shorter fiber length compared to Kevlar filament allows for easier processing into nonwoven fabrics and blended yarns, enhancing comfort and durability in applications like body armor and high-performance gloves. This versatility makes Kevlar staple essential in industries requiring lightweight, impact-resistant materials.

Cost Analysis: Filament vs Staple

Kevlar filament offers higher tensile strength and durability compared to Kevlar staple, resulting in superior performance for technical applications but at a significantly higher production cost due to complex spinning processes. Kevlar staple fibers, while less expensive and easier to process, provide adequate strength for general use, making them a cost-effective option for textiles and composite reinforcements where premium performance is not critical. Cost analysis reveals that the choice between filament and staple Kevlar depends on balancing budget constraints with required material properties for specific industrial needs.

Environmental Impact and Sustainability

Kevlar filament, characterized by long continuous fibers, offers superior strength and durability, resulting in extended product lifespans and reduced material waste, which contribute to lower environmental impact compared to Kevlar staple fibers. Kevlar staple fibers, shorter and cut-length, typically lead to higher processing losses and increased energy consumption during manufacturing, elevating their overall environmental footprint. Choosing Kevlar filament enhances sustainability by minimizing resource use and supporting circular economy principles through improved recyclability and longevity of finished products.

Choosing Between Kevlar Filament and Staple

Kevlar filament offers superior tensile strength and consistent fiber alignment, making it ideal for high-performance applications like ballistic protection and aerospace composites. Kevlar staple fibers, with their shorter length and fluffier texture, provide better flexibility and bulk, suitable for textile manufacturing and cushioning materials. Selecting between Kevlar filament and staple depends on the required balance of strength, durability, and material handling characteristics for the intended use.

Kevlar filament vs Kevlar staple Infographic

materialdif.com

materialdif.com