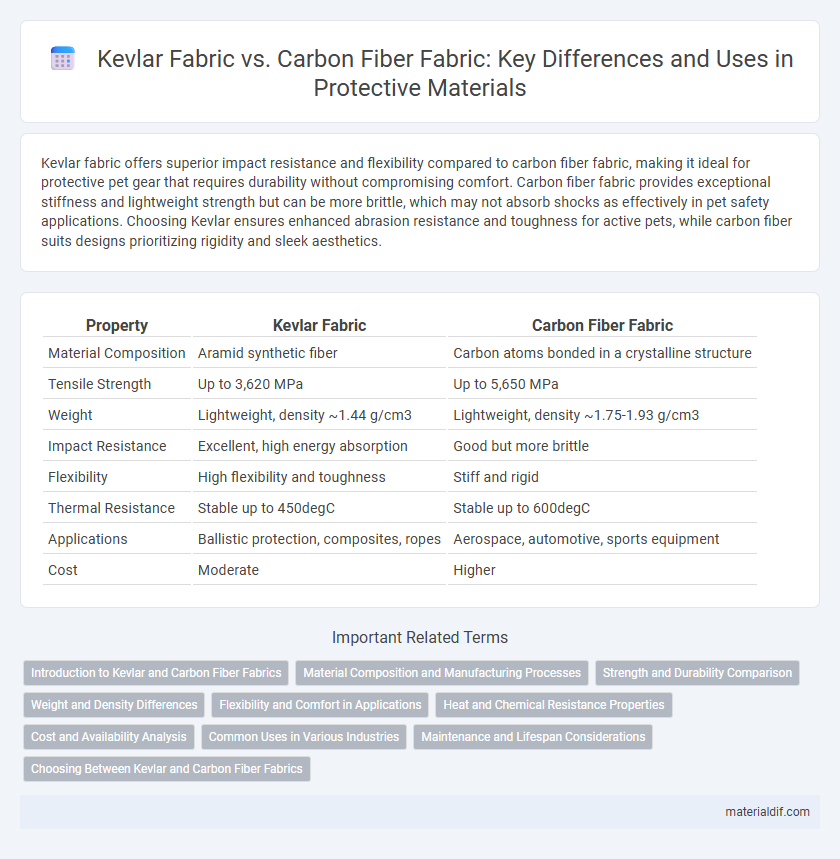

Kevlar fabric offers superior impact resistance and flexibility compared to carbon fiber fabric, making it ideal for protective pet gear that requires durability without compromising comfort. Carbon fiber fabric provides exceptional stiffness and lightweight strength but can be more brittle, which may not absorb shocks as effectively in pet safety applications. Choosing Kevlar ensures enhanced abrasion resistance and toughness for active pets, while carbon fiber suits designs prioritizing rigidity and sleek aesthetics.

Table of Comparison

| Property | Kevlar Fabric | Carbon Fiber Fabric |

|---|---|---|

| Material Composition | Aramid synthetic fiber | Carbon atoms bonded in a crystalline structure |

| Tensile Strength | Up to 3,620 MPa | Up to 5,650 MPa |

| Weight | Lightweight, density ~1.44 g/cm3 | Lightweight, density ~1.75-1.93 g/cm3 |

| Impact Resistance | Excellent, high energy absorption | Good but more brittle |

| Flexibility | High flexibility and toughness | Stiff and rigid |

| Thermal Resistance | Stable up to 450degC | Stable up to 600degC |

| Applications | Ballistic protection, composites, ropes | Aerospace, automotive, sports equipment |

| Cost | Moderate | Higher |

Introduction to Kevlar and Carbon Fiber Fabrics

Kevlar fabric, known for its exceptional tensile strength-to-weight ratio, is a synthetic aramid fiber widely used in ballistic protection, aerospace, and sports equipment. Carbon fiber fabric consists of thin, strong crystalline filaments of carbon, valued for its rigidity, high stiffness, and lightweight properties in automotive, aerospace, and civil engineering applications. Both materials provide superior strength and durability, with Kevlar excelling in impact resistance and carbon fiber distinguished by its high modulus and stiffness.

Material Composition and Manufacturing Processes

Kevlar fabric consists of para-aramid synthetic fibers, renowned for their high tensile strength-to-weight ratio and exceptional impact resistance, while carbon fiber fabric is composed of thin strands of carbon atoms bonded in a crystalline formation, providing superior stiffness and thermal conductivity. Kevlar is typically produced through a wet-spinning process where polymer solution is extruded and solidified, whereas carbon fiber manufacturing involves the carbonization of polyacrylonitrile (PAN) fibers at extremely high temperatures in an inert atmosphere. Differences in material composition and manufacturing processes result in Kevlar fabrics favoring flexibility and energy absorption, while carbon fiber fabrics excel in rigidity and structural applications.

Strength and Durability Comparison

Kevlar fabric exhibits exceptional tensile strength and impact resistance, making it highly durable in high-stress environments, outperforming many traditional materials. Carbon fiber fabric offers superior stiffness and higher compressive strength but is more brittle and prone to cracking under impact compared to Kevlar. The combination of Kevlar's flexibility and abrasion resistance often results in longer-lasting performance in applications requiring both strength and durability.

Weight and Density Differences

Kevlar fabric exhibits a lower density of approximately 1.44 g/cm3 compared to carbon fiber fabric, which typically ranges from 1.7 to 1.95 g/cm3, resulting in Kevlar being significantly lighter. This lower density contributes to Kevlar's advantage in applications requiring weight savings without compromising strength, such as in ballistic protection and aerospace components. Despite its lighter weight, Kevlar also offers excellent tensile strength, making it a preferred choice when reducing overall material mass is critical.

Flexibility and Comfort in Applications

Kevlar fabric offers superior flexibility and comfort compared to carbon fiber fabric, making it ideal for applications requiring lightweight protection and ease of movement, such as in protective clothing and sports gear. Carbon fiber fabric, while exceptionally strong and stiff, tends to be more rigid and less comfortable for wearables due to its limited flexibility. Kevlar's ability to bend and conform to body shapes enhances wearer comfort without compromising durability, whereas carbon fiber is better suited for structural components requiring high rigidity.

Heat and Chemical Resistance Properties

Kevlar fabric offers superior heat resistance, maintaining its strength and integrity at temperatures up to 450degC, whereas carbon fiber fabric can withstand higher temperatures but tends to degrade when exposed to certain chemicals. Kevlar's exceptional chemical resistance makes it ideal for environments with exposure to solvents, acids, and alkalis, while carbon fiber fabrics often require specialized coatings to prevent chemical damage. The combination of high thermal stability and chemical durability makes Kevlar fabric a preferred choice for protective garments and industrial applications requiring robust heat and chemical resistance.

Cost and Availability Analysis

Kevlar fabric generally offers lower material costs compared to carbon fiber fabric, making it a more budget-friendly option for applications requiring high strength and impact resistance. Availability of Kevlar tends to be higher due to its widespread manufacturing and longer market presence, resulting in easier sourcing for industries such as automotive, aerospace, and protective gear. Carbon fiber fabric remains more expensive with limited suppliers, reflecting its cutting-edge performance benefits and specialized production processes.

Common Uses in Various Industries

Kevlar fabric is widely used in personal protective equipment such as bulletproof vests and helmets due to its exceptional impact resistance and lightweight properties. Carbon fiber fabric is predominantly utilized in aerospace, automotive, and sporting goods industries for its superior stiffness and high strength-to-weight ratio. Both materials are integral in manufacturing high-performance composites tailored to specific applications requiring durability and rigidity.

Maintenance and Lifespan Considerations

Kevlar fabric offers superior impact resistance and flexibility, resulting in lower maintenance requirements compared to carbon fiber fabric, which is more brittle and prone to micro-cracking. Kevlar's chemical stability and resistance to UV degradation contribute to its longer lifespan in harsh environments, whereas carbon fiber fabric may require more frequent inspections and repairs to maintain structural integrity. Selecting Kevlar fabric for applications demanding durability and ease of upkeep enhances long-term performance and cost efficiency.

Choosing Between Kevlar and Carbon Fiber Fabrics

Kevlar fabric offers superior impact resistance and flexibility, making it ideal for protective gear and applications requiring shock absorption. Carbon fiber fabric provides exceptional stiffness and high tensile strength, suitable for structural components demanding lightweight and rigidity. Choice depends on whether priority is durability and flexibility with Kevlar or lightweight strength and rigidity with carbon fiber.

Kevlar fabric vs Carbon fiber fabric Infographic

materialdif.com

materialdif.com