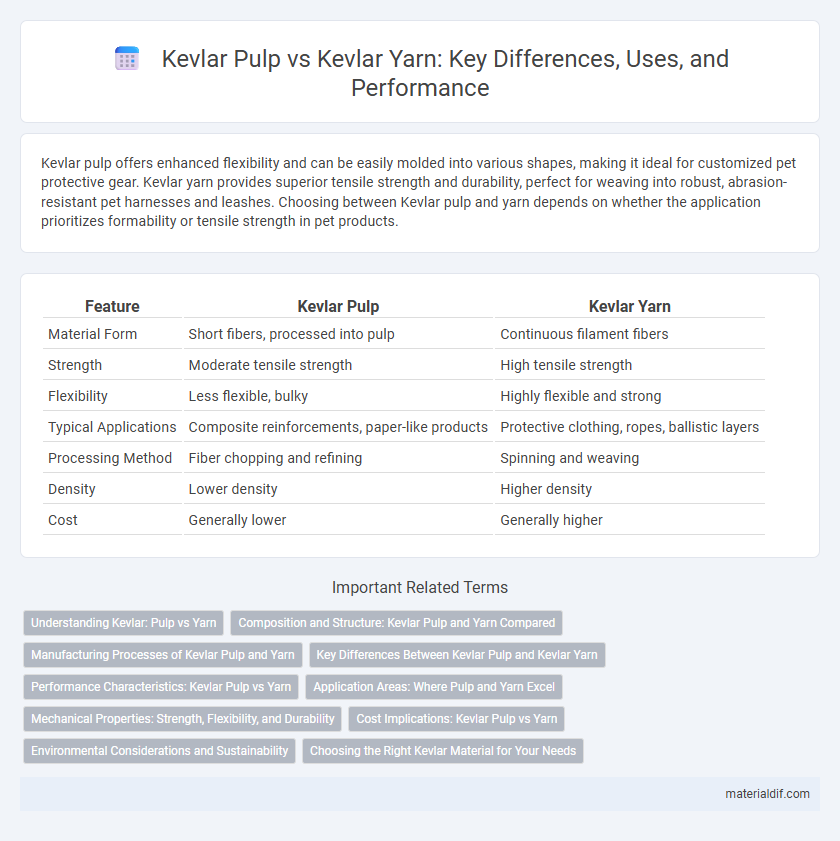

Kevlar pulp offers enhanced flexibility and can be easily molded into various shapes, making it ideal for customized pet protective gear. Kevlar yarn provides superior tensile strength and durability, perfect for weaving into robust, abrasion-resistant pet harnesses and leashes. Choosing between Kevlar pulp and yarn depends on whether the application prioritizes formability or tensile strength in pet products.

Table of Comparison

| Feature | Kevlar Pulp | Kevlar Yarn |

|---|---|---|

| Material Form | Short fibers, processed into pulp | Continuous filament fibers |

| Strength | Moderate tensile strength | High tensile strength |

| Flexibility | Less flexible, bulky | Highly flexible and strong |

| Typical Applications | Composite reinforcements, paper-like products | Protective clothing, ropes, ballistic layers |

| Processing Method | Fiber chopping and refining | Spinning and weaving |

| Density | Lower density | Higher density |

| Cost | Generally lower | Generally higher |

Understanding Kevlar: Pulp vs Yarn

Kevlar pulp consists of short, chopped fibers ideal for creating composite materials with enhanced strength and flexibility, while Kevlar yarn comprises long continuous fibers used in textiles and protective gear for superior tensile strength. Kevlar yarn offers higher durability and resistance to abrasion, making it suitable for applications like ballistic vests and ropes, whereas Kevlar pulp is favored in molding and reinforcement applications. Understanding the structural differences between Kevlar pulp and yarn highlights their distinct roles in industrial and safety equipment manufacturing.

Composition and Structure: Kevlar Pulp and Yarn Compared

Kevlar pulp consists of short, chopped fibers with a random orientation, creating a non-woven matrix ideal for enhancing composite materials through uniform dispersion. Kevlar yarn, in contrast, is composed of continuous, highly aligned fibers twisted into threads, providing superior tensile strength and flexibility for textiles and ballistic applications. The structural differences between pulp and yarn result in distinct mechanical properties, where pulp offers improved toughness and energy absorption, while yarn delivers enhanced strength and abrasion resistance.

Manufacturing Processes of Kevlar Pulp and Yarn

Kevlar pulp is produced by mechanically fibrillating bulk Kevlar fibers into fine microfibers, enhancing its surface area for better bonding in composite materials. Kevlar yarn is manufactured through a spinning process that aligns aramid polymer chains into high-strength fibers, which are then twisted to form continuous yarns used in textiles and ballistic applications. The pulp process emphasizes fiber fragmentation for improved matrix adhesion, while the yarn process focuses on molecular orientation for maximum tensile strength.

Key Differences Between Kevlar Pulp and Kevlar Yarn

Kevlar pulp consists of short, chopped fibers used primarily to enhance paper strength, while Kevlar yarn is composed of long, continuous filaments designed for fabric and composite reinforcement. The tensile strength of Kevlar yarn is superior due to its filament continuity, making it ideal for ballistic and protective applications. Kevlar pulp is favored in paper manufacturing for its ability to increase tear resistance without compromising flexibility.

Performance Characteristics: Kevlar Pulp vs Yarn

Kevlar yarn offers superior tensile strength and flexibility, making it ideal for applications requiring high durability and impact resistance. Kevlar pulp, being a shorter fiber form, provides excellent reinforcement in composite materials with enhanced thermal stability and ease of dispersion. Performance characteristics of Kevlar yarn emphasize load-bearing capacity, while Kevlar pulp excels in distribution uniformity and composite matrix compatibility.

Application Areas: Where Pulp and Yarn Excel

Kevlar yarn is predominantly used in applications requiring high tensile strength and flexibility, such as bulletproof vests, ropes, and protective clothing, due to its continuous fiber structure. Kevlar pulp, composed of short fibers, excels in enhancing the mechanical properties of composite materials, filtration media, and specialty papers where uniform dispersion and reinforcement are critical. The choice between Kevlar pulp and yarn depends on the specific performance needs in aerospace, automotive, and industrial safety sectors.

Mechanical Properties: Strength, Flexibility, and Durability

Kevlar pulp exhibits enhanced flexibility and ease of integration into composite materials, making it ideal for applications requiring moldability and impact resistance. Kevlar yarn offers superior tensile strength and durability, providing excellent load-bearing capacity and long-term performance in high-stress environments. The mechanical properties of Kevlar yarn generally surpass pulp in strength and durability, while Kevlar pulp excels in flexibility and conformability.

Cost Implications: Kevlar Pulp vs Yarn

Kevlar pulp generally offers a lower cost per unit compared to Kevlar yarn due to its less complex manufacturing process and bulk production capabilities. Kevlar yarn, used for high-strength applications like body armor and aerospace, demands more processing steps and quality control, leading to higher prices. Businesses must weigh the cost-effectiveness of Kevlar pulp for composite reinforcement against the premium investment required for Kevlar yarn's superior tensile strength and durability.

Environmental Considerations and Sustainability

Kevlar pulp offers enhanced sustainability benefits compared to Kevlar yarn due to its lower energy consumption during production and reduced waste generation. The pulp form facilitates recycling processes and decreases the carbon footprint associated with traditional yarn spinning. By prioritizing Kevlar pulp, industries can achieve greater environmental responsibility while maintaining the material's inherent strength and durability.

Choosing the Right Kevlar Material for Your Needs

Kevlar pulp offers a fine, flexible form ideal for enhancing composite materials and improving impact resistance in coatings and papers. Kevlar yarn provides high tensile strength and durability, making it suitable for woven fabrics used in body armor and industrial applications. Selecting between Kevlar pulp and yarn depends on whether the priority is material flexibility and integration or structural strength and abrasion resistance.

Kevlar pulp vs Kevlar yarn Infographic

materialdif.com

materialdif.com