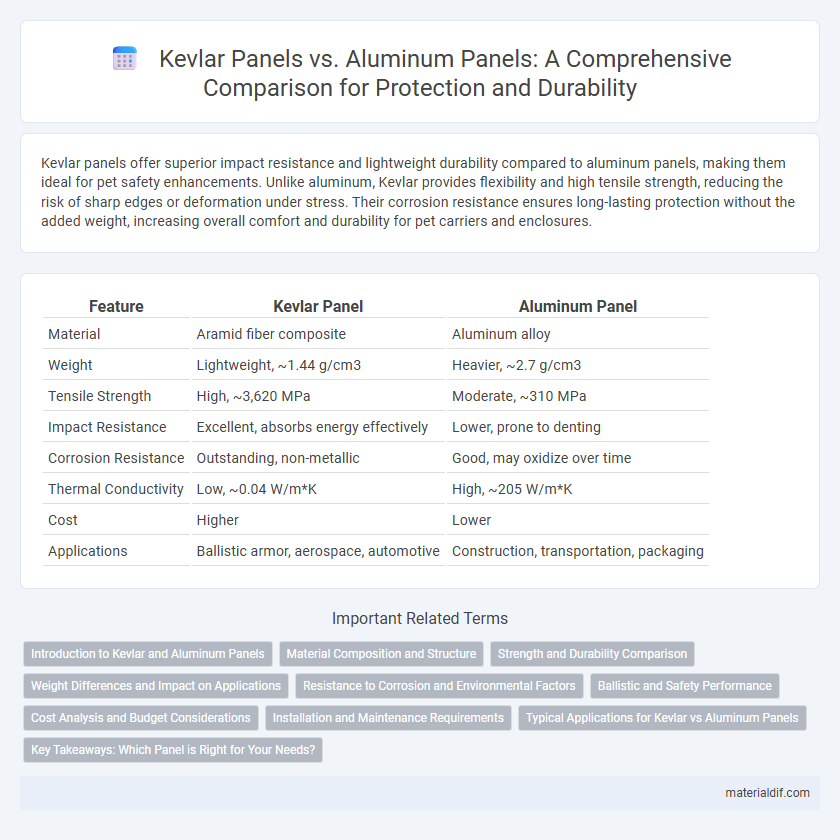

Kevlar panels offer superior impact resistance and lightweight durability compared to aluminum panels, making them ideal for pet safety enhancements. Unlike aluminum, Kevlar provides flexibility and high tensile strength, reducing the risk of sharp edges or deformation under stress. Their corrosion resistance ensures long-lasting protection without the added weight, increasing overall comfort and durability for pet carriers and enclosures.

Table of Comparison

| Feature | Kevlar Panel | Aluminum Panel |

|---|---|---|

| Material | Aramid fiber composite | Aluminum alloy |

| Weight | Lightweight, ~1.44 g/cm3 | Heavier, ~2.7 g/cm3 |

| Tensile Strength | High, ~3,620 MPa | Moderate, ~310 MPa |

| Impact Resistance | Excellent, absorbs energy effectively | Lower, prone to denting |

| Corrosion Resistance | Outstanding, non-metallic | Good, may oxidize over time |

| Thermal Conductivity | Low, ~0.04 W/m*K | High, ~205 W/m*K |

| Cost | Higher | Lower |

| Applications | Ballistic armor, aerospace, automotive | Construction, transportation, packaging |

Introduction to Kevlar and Aluminum Panels

Kevlar panels, made from aramid fibers, offer exceptional strength-to-weight ratio and impact resistance, making them ideal for protective applications compared to aluminum panels known for their lightweight and corrosion resistance. Aluminum panels provide excellent thermal conductivity and structural rigidity but can be prone to denting under high impact, whereas Kevlar panels maintain integrity under stress due to their fiber-reinforced composite structure. These material properties define their usage across industries such as aerospace, automotive, and defense, with Kevlar often preferred for ballistic protection and aluminum for structural frameworks.

Material Composition and Structure

Kevlar panels are composed of aramid fibers known for their high tensile strength and impact resistance, arranged in a woven or layered fabric structure that provides exceptional energy absorption and flexibility. Aluminum panels consist of lightweight metal alloys with a crystalline structure offering rigidity, thermal conductivity, and corrosion resistance but lower impact flexibility compared to Kevlar. The composite structure of Kevlar panels allows superior ballistic protection and weight efficiency, making them ideal for protective gear, while aluminum panels excel in structural applications requiring stiffness and durability.

Strength and Durability Comparison

Kevlar panels exhibit superior strength-to-weight ratio compared to aluminum panels, making them highly resistant to impacts and punctures while maintaining lightweight properties. Kevlar's exceptional tensile strength and resistance to corrosion provide enhanced durability, especially in harsh environments where aluminum may suffer from oxidation and fatigue. Long-term performance of Kevlar panels often surpasses aluminum, as they retain structural integrity under repeated stress and resist deforming over time.

Weight Differences and Impact on Applications

Kevlar panels weigh significantly less than aluminum panels, offering a weight reduction of up to 50%, which enhances fuel efficiency and maneuverability in aerospace and automotive applications. The lower density of Kevlar maintains structural integrity while reducing overall mass, making it ideal for lightweight protective gear and impact-resistant components. This weight advantage directly impacts performance by enabling faster acceleration, improved load capacity, and easier handling in various engineering designs.

Resistance to Corrosion and Environmental Factors

Kevlar panels exhibit superior resistance to corrosion compared to aluminum panels, as Kevlar is a synthetic aramid fiber impervious to rust and oxidation. Environmental factors such as moisture, saltwater, and extreme temperatures have minimal impact on Kevlar's structural integrity, whereas aluminum panels can suffer from corrosion and oxidation over time in harsh conditions. Kevlar's durability in corrosive environments makes it ideal for applications requiring long-term exposure to challenging environmental elements.

Ballistic and Safety Performance

Kevlar panels exhibit superior ballistic resistance due to their high tensile strength-to-weight ratio, effectively dispersing impact energy from projectiles and reducing penetration risk. Unlike aluminum panels, which may deform or fracture upon impact, Kevlar maintains structural integrity, enhancing safety in ballistic protection applications. Consequently, Kevlar panels are preferred in armor systems where lightweight durability and high-level ballistic performance are critical.

Cost Analysis and Budget Considerations

Kevlar panels generally exhibit higher upfront costs compared to aluminum panels due to the advanced materials and manufacturing processes involved. However, Kevlar's superior impact resistance and durability can lead to lower long-term maintenance and replacement expenses, offering potential cost savings over the lifespan of the panel. Budget considerations should weigh initial investment against lifecycle costs, with Kevlar being advantageous in applications requiring enhanced strength and weight reduction.

Installation and Maintenance Requirements

Kevlar panels offer easier installation due to their lightweight and flexible nature, reducing labor time and structural support needs compared to heavier aluminum panels. Maintenance requirements for Kevlar panels are minimal since they resist corrosion and impacts, unlike aluminum panels which require regular inspections for oxidation and potential dents. Choosing Kevlar panels enhances long-term durability while lowering upkeep costs in demanding environments.

Typical Applications for Kevlar vs Aluminum Panels

Kevlar panels are extensively used in ballistic protection, aerospace components, and automotive parts where lightweight strength and impact resistance are critical, outperforming aluminum panels in high-stress and safety-focused applications. Aluminum panels dominate in construction, transportation, and marine industries due to their excellent corrosion resistance, ease of fabrication, and cost-effectiveness for structural and exterior surfaces. The choice between Kevlar and aluminum panels depends heavily on the specific requirements for weight, durability, and environmental exposure in applications ranging from defense gear to architectural cladding.

Key Takeaways: Which Panel is Right for Your Needs?

Kevlar panels offer exceptional impact resistance and lightweight durability, making them ideal for applications requiring high strength-to-weight ratios, such as protective gear and aerospace components. Aluminum panels provide superior rigidity and corrosion resistance, suited for structural uses where longevity and load-bearing capacity are critical. Choosing between Kevlar and aluminum panels depends on balancing the need for flexibility and lightweight protection against structural strength and environmental resilience.

Kevlar Panel vs Aluminum Panel Infographic

materialdif.com

materialdif.com