Kevlar sheets offer flexibility and are ideal for custom applications requiring lightweight, high-strength material, while Kevlar panels provide rigid support suitable for structural reinforcement. The choice between Kevlar sheet and Kevlar panel depends on the specific durability and form factor needs of the pet product. Both materials deliver exceptional impact resistance and abrasion protection, enhancing pet safety in demanding environments.

Table of Comparison

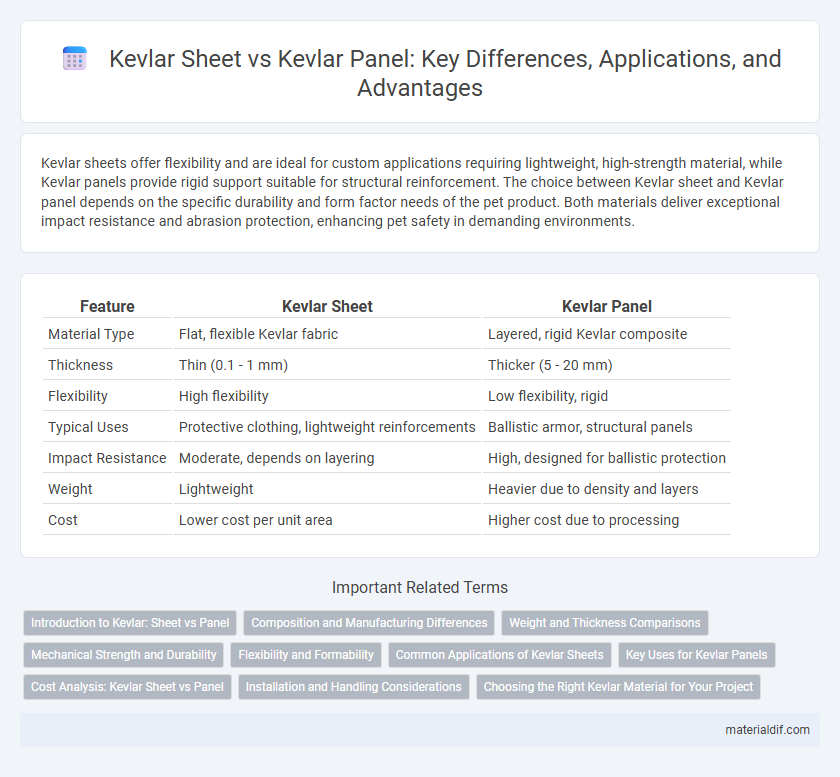

| Feature | Kevlar Sheet | Kevlar Panel |

|---|---|---|

| Material Type | Flat, flexible Kevlar fabric | Layered, rigid Kevlar composite |

| Thickness | Thin (0.1 - 1 mm) | Thicker (5 - 20 mm) |

| Flexibility | High flexibility | Low flexibility, rigid |

| Typical Uses | Protective clothing, lightweight reinforcements | Ballistic armor, structural panels |

| Impact Resistance | Moderate, depends on layering | High, designed for ballistic protection |

| Weight | Lightweight | Heavier due to density and layers |

| Cost | Lower cost per unit area | Higher cost due to processing |

Introduction to Kevlar: Sheet vs Panel

Kevlar sheets are thin, flexible layers of aramid fiber used primarily for applications requiring lightweight, high-strength materials such as protective gear and insulation. Kevlar panels, composed of multiple laminated sheets, offer enhanced structural integrity and are commonly utilized in ballistic armor, automotive, and aerospace industries for improved impact resistance. Both forms leverage Kevlar's exceptional tensile strength and heat resistance, but panels provide greater durability and thickness for heavy-duty protection.

Composition and Manufacturing Differences

Kevlar sheets consist of woven or non-woven aramid fibers bonded by a resin matrix, offering flexibility and ease of cutting for customized applications. In contrast, Kevlar panels are rigid composites formed by layering multiple Kevlar sheets, often combined with epoxy or other thermosetting resins through compression molding or autoclave curing processes. The manufacturing differences result in sheets being preferred for lightweight, adaptable uses, while panels provide enhanced structural strength and impact resistance in protective gear and aerospace components.

Weight and Thickness Comparisons

Kevlar sheets generally offer a thinner and lighter option compared to Kevlar panels, making them ideal for applications requiring flexibility and minimal bulk. Kevlar panels are typically thicker and heavier, providing enhanced structural strength and impact resistance for use in body armor and protective gear. Weight differences vary based on the weave style and resin infusion, with Kevlar sheets averaging around 0.2 to 0.5 pounds per square foot, whereas panels can exceed 1 pound per square foot depending on layering.

Mechanical Strength and Durability

Kevlar sheets typically offer uniform mechanical strength due to their consistent fiber alignment, making them ideal for applications requiring flexibility and lightweight protection. Kevlar panels, however, are engineered with multiple layers and specific resin systems, resulting in enhanced durability and resistance to impact and abrasion. The increased thickness and structural composition of Kevlar panels provide superior mechanical strength and longer service life compared to single-layer Kevlar sheets.

Flexibility and Formability

Kevlar sheets offer superior flexibility, allowing for easier shaping and bending during fabrication, making them ideal for applications requiring intricate contours. Kevlar panels, on the other hand, provide enhanced structural rigidity and strength but are less formable, suited for flat or gently curved surfaces where durability is paramount. Selecting between Kevlar sheet and panel depends on balancing the need for flexibility with the desired level of mechanical stiffness in the final product.

Common Applications of Kevlar Sheets

Kevlar sheets are widely used in ballistic protection gear, including body armor and helmets, due to their high tensile strength and lightweight properties. They find common applications in aerospace components and automotive parts where impact resistance and durability are crucial. Compared to Kevlar panels, sheets offer greater flexibility, making them ideal for protective clothing and flexible composite materials.

Key Uses for Kevlar Panels

Kevlar panels are widely used in ballistic armor applications, providing enhanced protection for body armor, helmets, and vehicle armor due to their high tensile strength and lightweight properties. These panels are essential in aerospace and automotive industries, improving impact resistance and weight reduction in structural components. Kevlar sheets, by contrast, are primarily utilized for fabric applications like reinforcement layers in composite materials and protective clothing.

Cost Analysis: Kevlar Sheet vs Panel

Kevlar sheets generally offer a more cost-effective solution for small-scale or custom applications where precise dimensions and flexibility are required, reducing material waste and handling expenses. Kevlar panels, while typically more expensive upfront due to their larger size and pre-fabrication costs, provide economies of scale and faster installation for extensive projects, lowering overall labor costs. Selecting between Kevlar sheet and panel depends on balancing initial material costs against installation efficiency and project scale.

Installation and Handling Considerations

Kevlar sheets offer greater flexibility and ease of cutting, making them ideal for applications requiring precise custom shapes and straightforward installation. Kevlar panels are typically pre-fabricated and larger, which may require specialized equipment and handling due to their rigidity and weight. Proper installation of either material involves ensuring secure fastening and avoiding excessive bending to maintain the structural integrity and performance characteristics of Kevlar.

Choosing the Right Kevlar Material for Your Project

Kevlar sheets offer flexibility and ease of customization, ideal for projects requiring precise cuts or layered configurations, while Kevlar panels provide pre-assembled, rigid structural support suited for impact resistance and ballistic protection. Selecting between Kevlar sheets and panels depends on the application's mechanical requirements, with sheets preferred for tailored shaping and panels favored for ready-to-use strength. Understanding factors like tensile strength, weight, and dimensional stability ensures optimal performance tailored to project-specific needs.

Kevlar sheet vs Kevlar panel Infographic

materialdif.com

materialdif.com