Kevlar reinforcement offers superior durability and resistance to wear compared to nylon reinforcement, making it ideal for high-stress pet gear such as harnesses and leashes. Kevlar fibers provide enhanced strength and cut resistance, ensuring longer-lasting protection and safety for pets in active environments. Nylon reinforcement, while flexible and lightweight, lacks the same level of toughness and abrasion resistance found in Kevlar, making it better suited for everyday, low-impact use.

Table of Comparison

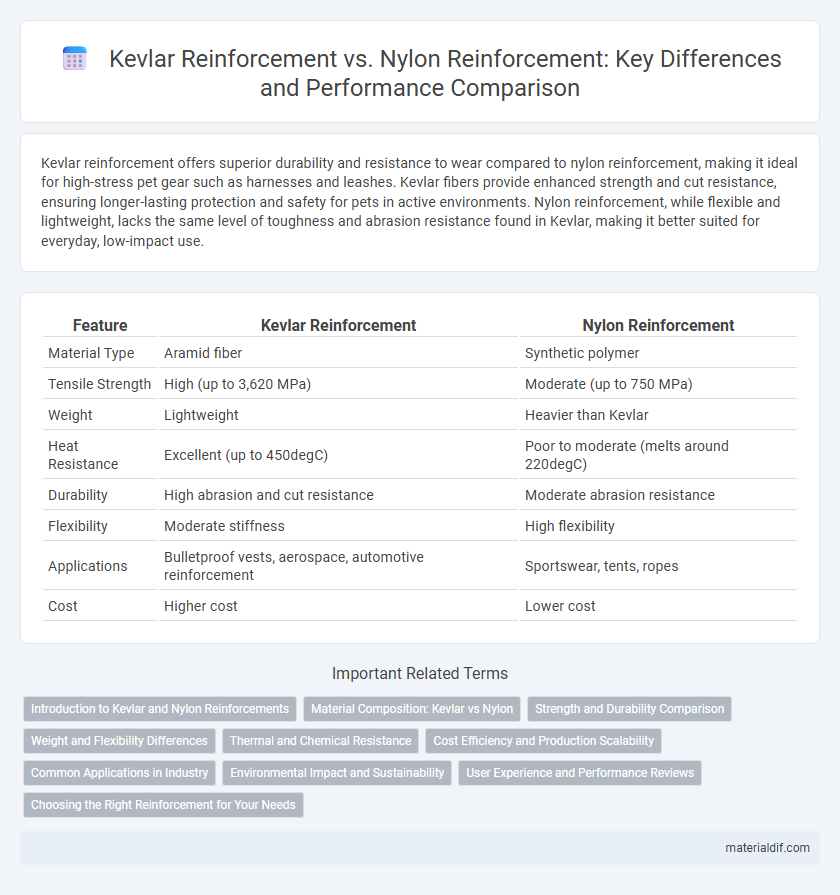

| Feature | Kevlar Reinforcement | Nylon Reinforcement |

|---|---|---|

| Material Type | Aramid fiber | Synthetic polymer |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 750 MPa) |

| Weight | Lightweight | Heavier than Kevlar |

| Heat Resistance | Excellent (up to 450degC) | Poor to moderate (melts around 220degC) |

| Durability | High abrasion and cut resistance | Moderate abrasion resistance |

| Flexibility | Moderate stiffness | High flexibility |

| Applications | Bulletproof vests, aerospace, automotive reinforcement | Sportswear, tents, ropes |

| Cost | Higher cost | Lower cost |

Introduction to Kevlar and Nylon Reinforcements

Kevlar reinforcement offers superior tensile strength and thermal resistance compared to nylon reinforcement, making it ideal for high-performance applications like bulletproof vests and aerospace components. Nylon reinforcements provide excellent flexibility and impact resistance, favored in applications requiring elasticity and durability under repetitive stress such as sports equipment and automotive parts. Both materials enhance composite structures, but Kevlar's unique aramid fiber composition delivers unmatched strength-to-weight ratios whereas nylon's polyamide structure excels in toughness and abrasion resistance.

Material Composition: Kevlar vs Nylon

Kevlar reinforcement consists of aramid fibers known for exceptional tensile strength and thermal stability, making it ideal for impact-resistant applications. Nylon reinforcement is composed of synthetic polyamide fibers that offer flexibility and abrasion resistance but lack Kevlar's high strength and heat resistance. The molecular structure of Kevlar provides superior durability and stiffness compared to nylon's more elastic and less heat-tolerant composition.

Strength and Durability Comparison

Kevlar reinforcement offers superior tensile strength and impact resistance compared to nylon, making it ideal for high-stress applications. Its molecular structure provides exceptional durability and resilience against abrasion and heat, outperforming nylon in long-term wear and tear. While nylon is flexible and cost-effective, Kevlar's enhanced strength-to-weight ratio ensures better performance in protective gear and industrial composites.

Weight and Flexibility Differences

Kevlar reinforcement offers superior strength-to-weight ratio compared to nylon, making it significantly lighter for equivalent tensile strength applications. Kevlar's stiffness reduces flexibility, while nylon provides greater elasticity and bendability, enhancing comfort and adaptability in dynamic conditions. Weight-conscious designs benefit from Kevlar's lightweight durability, whereas nylon is preferred where flexibility and stretchability are critical.

Thermal and Chemical Resistance

Kevlar reinforcement outperforms nylon reinforcement in thermal resistance, maintaining structural integrity at temperatures up to 450degC, whereas nylon typically degrades above 200degC. Chemically, Kevlar exhibits exceptional resistance to a wide range of solvents, acids, and alkalis, making it suitable for harsh environments where nylon may deteriorate or lose mechanical properties. This superior thermal and chemical stability makes Kevlar reinforcement ideal for applications requiring durability under extreme conditions.

Cost Efficiency and Production Scalability

Kevlar reinforcement offers superior strength-to-weight ratio and higher impact resistance compared to nylon, making it a preferred choice in high-performance applications despite its higher material cost. Nylon reinforcement tends to be more cost-efficient due to lower raw material prices and simpler manufacturing processes, enabling greater production scalability for mass-market products. The decision between Kevlar and nylon reinforcement depends on balancing budget constraints with performance requirements, where Kevlar suits specialized, high-stress environments and nylon supports cost-sensitive, large-scale manufacturing.

Common Applications in Industry

Kevlar reinforcement is widely used in ballistic-resistant gear, automotive tires, and aerospace components due to its high tensile strength and heat resistance. Nylon reinforcement finds common applications in fishing lines, ropes, and tire cords where flexibility, abrasion resistance, and cost-effectiveness are prioritized. Industries such as defense, automotive, and marine engineering select Kevlar or nylon based on specific performance requirements and environmental conditions.

Environmental Impact and Sustainability

Kevlar reinforcement offers superior durability and longer lifespan compared to nylon reinforcement, reducing the frequency of material replacement and waste generation. Kevlar production, however, involves energy-intensive processes and toxic chemical usage, whereas nylon manufacturing typically produces higher greenhouse gas emissions due to fossil fuel reliance. Sustainable alternatives are emerging in both fibers, but Kevlar's ability to improve product longevity contributes significantly to environmental impact mitigation in high-performance applications.

User Experience and Performance Reviews

Kevlar reinforcement outperforms nylon reinforcement in durability and impact resistance, providing enhanced safety and longevity for users in demanding environments. Performance reviews consistently highlight Kevlar's superior tensile strength and cut resistance, resulting in better protection and comfort during prolonged use. Users report improved confidence and reduced fatigue with Kevlar-reinforced gear compared to nylon alternatives due to its lightweight yet robust construction.

Choosing the Right Reinforcement for Your Needs

Kevlar reinforcement offers superior tensile strength and heat resistance, making it ideal for applications requiring exceptional durability and protection, such as ballistic and aerospace uses. Nylon reinforcement provides greater elasticity and abrasion resistance, suited for flexible, high-impact environments like sports equipment and outdoor gear. Selecting the right reinforcement depends on specific performance needs, environmental exposure, and weight considerations for optimal results.

Kevlar Reinforcement vs Nylon Reinforcement Infographic

materialdif.com

materialdif.com