Kevlar panels offer superior lightweight protection compared to traditional steel panels, making them ideal for enhancing pet safety without adding unnecessary weight. Their high tensile strength and flexibility absorb impacts more efficiently, reducing the risk of injury in case of accidents. Steel panels provide robust durability but can be significantly heavier, potentially causing discomfort or limiting mobility for pets.

Table of Comparison

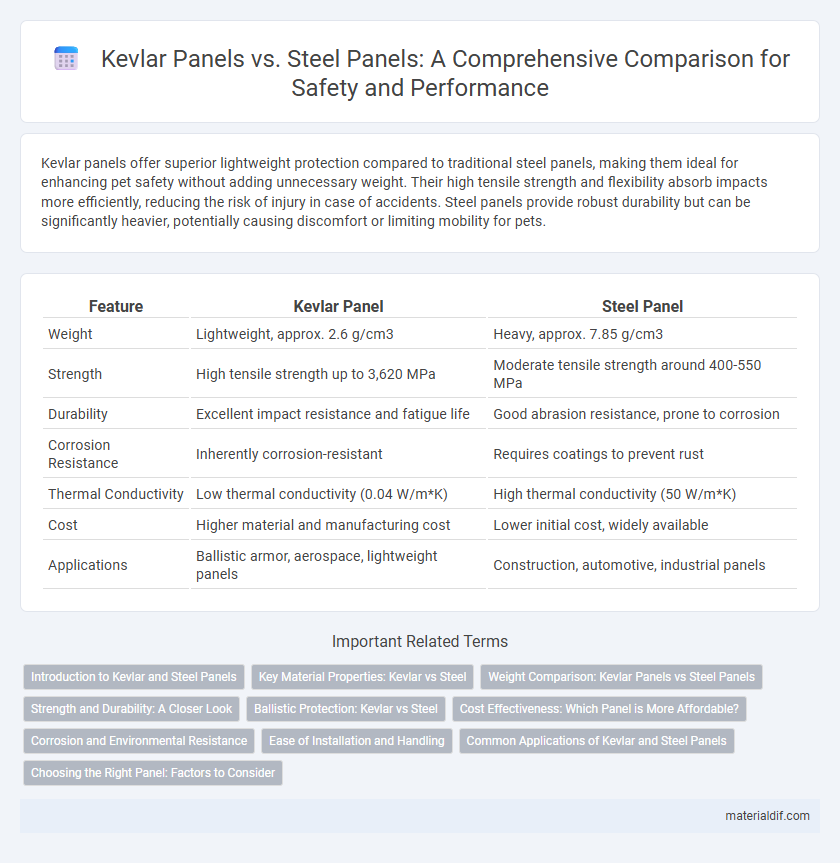

| Feature | Kevlar Panel | Steel Panel |

|---|---|---|

| Weight | Lightweight, approx. 2.6 g/cm3 | Heavy, approx. 7.85 g/cm3 |

| Strength | High tensile strength up to 3,620 MPa | Moderate tensile strength around 400-550 MPa |

| Durability | Excellent impact resistance and fatigue life | Good abrasion resistance, prone to corrosion |

| Corrosion Resistance | Inherently corrosion-resistant | Requires coatings to prevent rust |

| Thermal Conductivity | Low thermal conductivity (0.04 W/m*K) | High thermal conductivity (50 W/m*K) |

| Cost | Higher material and manufacturing cost | Lower initial cost, widely available |

| Applications | Ballistic armor, aerospace, lightweight panels | Construction, automotive, industrial panels |

Introduction to Kevlar and Steel Panels

Kevlar panels offer exceptional strength-to-weight ratios, making them highly effective for impact resistance and lightweight structural applications compared to traditional steel panels. Steel panels provide superior rigidity and durability but at a significantly higher weight, which can limit mobility and increase installation complexity. Kevlar's synthetic aramid fiber composition enables enhanced flexibility and corrosion resistance, distinguishing it from the dense, heavy properties of steel panels.

Key Material Properties: Kevlar vs Steel

Kevlar panels offer exceptional tensile strength and impact resistance while maintaining a significantly lower weight compared to steel panels, making them ideal for applications requiring lightweight armor solutions. Steel panels provide superior hardness and compressive strength but are considerably heavier, which can impact mobility and structural support. The inherent flexibility of Kevlar enhances energy absorption and reduces blunt force trauma, whereas steel's rigidity provides robust protection against penetration and deformation.

Weight Comparison: Kevlar Panels vs Steel Panels

Kevlar panels offer a significant weight advantage compared to steel panels, typically weighing up to 40% less while maintaining high tensile strength. This reduced weight improves fuel efficiency and vehicle maneuverability in automotive and aerospace applications. Steel panels, although heavier, provide excellent rigidity but add substantial mass, making Kevlar the preferred choice for weight-sensitive designs.

Strength and Durability: A Closer Look

Kevlar panels exhibit superior tensile strength and impact resistance compared to steel panels, making them ideal for applications requiring lightweight and durable materials. The inherent molecular structure of Kevlar fibers provides excellent energy absorption and flexibility, which enhances durability under repeated stress and environmental exposure. Unlike steel, Kevlar panels resist corrosion and fatigue, extending their lifespan in harsh conditions without compromising structural integrity.

Ballistic Protection: Kevlar vs Steel

Kevlar panels offer superior ballistic protection compared to steel panels due to their lightweight and high tensile strength properties, effectively absorbing and dispersing impact energy from bullets and shrapnel. Unlike steel panels, Kevlar resists penetration without significant deformation, reducing ricochet risks and providing enhanced flexibility for armor applications. The material's ability to maintain structural integrity under high-velocity impacts makes Kevlar panels a preferred choice in personal body armor and vehicle protection systems.

Cost Effectiveness: Which Panel is More Affordable?

Kevlar panels generally offer higher cost-effectiveness than steel panels due to their lightweight nature, reducing transportation and installation expenses. While the initial purchase price of Kevlar panels may be higher, their durability and longer lifespan lower maintenance and replacement costs over time. Steel panels incur higher costs related to corrosion protection and heavier structural support requirements, making Kevlar a more affordable option in long-term applications.

Corrosion and Environmental Resistance

Kevlar panels exhibit superior corrosion resistance compared to steel panels, as they do not oxidize or rust when exposed to moisture or harsh environmental conditions. The inherent chemical stability of Kevlar fibers ensures long-term durability and reduced maintenance costs, especially in marine or chemically aggressive environments. Steel panels require protective coatings to mitigate corrosion, which can degrade over time and compromise structural integrity.

Ease of Installation and Handling

Kevlar panels are significantly lighter than steel panels, enhancing ease of installation and reducing labor costs. Their flexibility allows for easier cutting and shaping on-site, minimizing the need for specialized tools. Unlike steel, Kevlar panels do not require heavy lifting equipment, streamlining the handling process during construction.

Common Applications of Kevlar and Steel Panels

Kevlar panels are widely used in ballistic armor, aerospace components, and protective gear due to their high tensile strength and lightweight properties. Steel panels are commonly applied in construction, automotive manufacturing, and industrial machinery where durability and impact resistance are critical. Both materials serve distinct roles, with Kevlar excelling in personal and aerospace protection and steel dominating structural and heavy-duty applications.

Choosing the Right Panel: Factors to Consider

Kevlar panels offer superior impact resistance and lighter weight compared to steel panels, making them ideal for applications requiring enhanced ballistic protection and weight reduction. Steel panels provide greater rigidity and higher cost-efficiency, suitable for structural strength where weight is less critical. When choosing the right panel, consider factors like required durability, weight constraints, cost, and specific environmental conditions such as corrosion exposure.

Kevlar Panel vs Steel Panel Infographic

materialdif.com

materialdif.com