Kevlar-coated gloves provide superior cut resistance and durability compared to nitrile-coated gloves, making them ideal for handling sharp objects and heavy-duty tasks. Nitrile-coated gloves offer excellent chemical resistance and flexibility, which is beneficial for tasks requiring dexterity and protection against oils and solvents. Choosing between Kevlar and nitrile-coated gloves depends on the specific hazards and requirements of the job.

Table of Comparison

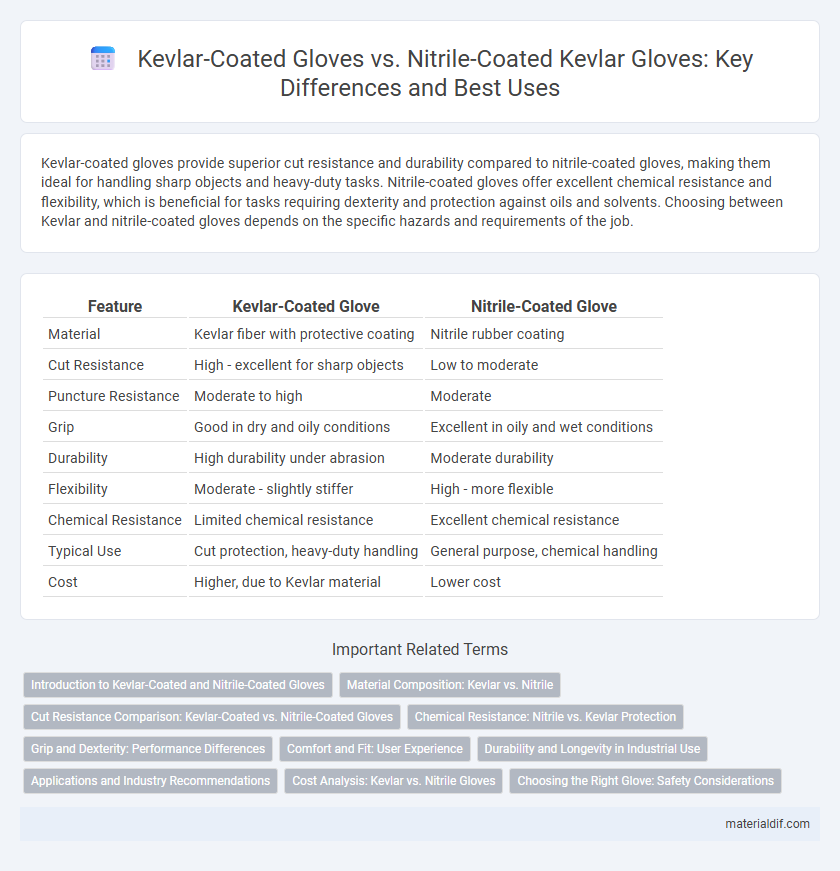

| Feature | Kevlar-Coated Glove | Nitrile-Coated Glove |

|---|---|---|

| Material | Kevlar fiber with protective coating | Nitrile rubber coating |

| Cut Resistance | High - excellent for sharp objects | Low to moderate |

| Puncture Resistance | Moderate to high | Moderate |

| Grip | Good in dry and oily conditions | Excellent in oily and wet conditions |

| Durability | High durability under abrasion | Moderate durability |

| Flexibility | Moderate - slightly stiffer | High - more flexible |

| Chemical Resistance | Limited chemical resistance | Excellent chemical resistance |

| Typical Use | Cut protection, heavy-duty handling | General purpose, chemical handling |

| Cost | Higher, due to Kevlar material | Lower cost |

Introduction to Kevlar-Coated and Nitrile-Coated Gloves

Kevlar-coated gloves provide exceptional cut resistance and durability due to their aramid fiber composition, making them ideal for high-risk industrial tasks. Nitrile-coated gloves offer superior chemical resistance and excellent grip in wet or oily conditions, often used in medical or mechanical environments. Both glove types enhance hand protection but serve different functional needs depending on the work environment.

Material Composition: Kevlar vs. Nitrile

Kevlar-coated gloves feature a high-performance para-aramid fiber known for exceptional cut resistance, heat protection, and durability in demanding work environments. Nitrile-coated gloves utilize a synthetic rubber polymer, offering excellent chemical resistance, puncture protection, and superior grip on oily or wet surfaces. The distinct material compositions of Kevlar and Nitrile directly influence glove performance: Kevlar excels in cut and heat resistance, while Nitrile prioritizes chemical defense and tactile sensitivity.

Cut Resistance Comparison: Kevlar-Coated vs. Nitrile-Coated Gloves

Kevlar-coated gloves offer superior cut resistance compared to nitrile-coated gloves due to their aramid fiber composition, which can withstand higher abrasion and slicing forces. Nitrile-coated gloves provide excellent chemical resistance and some cut protection but typically fail to match the durability and sharp object resistance of Kevlar fibers. For applications involving sharp tools or materials, Kevlar-coated gloves significantly reduce the risk of lacerations, making them the preferred choice for high cut-risk environments.

Chemical Resistance: Nitrile vs. Kevlar Protection

Nitrile-coated gloves demonstrate superior chemical resistance against oils, solvents, and various hazardous substances compared to Kevlar-coated gloves, which primarily offer cut and abrasion protection. Kevlar fibers provide excellent mechanical durability but lack the chemical barrier properties present in nitrile coatings. For environments requiring protection against harsh chemicals and solvents, nitrile-coated gloves are the preferred choice, whereas Kevlar-coated gloves excel in cut-resistant applications.

Grip and Dexterity: Performance Differences

Kevlar-coated gloves offer superior cut resistance and durability while maintaining excellent grip and dexterity, especially in environments requiring precision handling. Nitrile-coated gloves provide enhanced chemical resistance and a tackier surface for better grip on oily or wet objects but may compromise fine motor skills due to their thicker coating. Performance differences highlight Kevlar gloves as optimal for tasks demanding both protection and tactile sensitivity, whereas nitrile gloves excel in chemical safety with good grip on slippery surfaces.

Comfort and Fit: User Experience

Kevlar-coated gloves provide enhanced cut resistance and durability while maintaining a snug fit that contours to the hand for superior dexterity and prolonged wear comfort. Nitrile-coated gloves offer excellent chemical resistance and a flexible fit, yet they may feel less breathable compared to Kevlar, potentially causing discomfort during extended use. Users seeking a balance between protection and comfort often prefer Kevlar gloves for tasks requiring precision and longer wear time.

Durability and Longevity in Industrial Use

Kevlar-coated gloves offer superior durability and longevity in industrial use due to their high tensile strength and resistance to abrasion, cuts, and heat, making them ideal for heavy-duty tasks. Nitrile-coated gloves provide excellent chemical resistance and puncture protection but typically wear out faster under intense mechanical stress. Choosing Kevlar-coated gloves ensures extended service life and reduced replacement costs in demanding environments.

Applications and Industry Recommendations

Kevlar-coated gloves offer superior cut resistance and heat protection, making them ideal for heavy-duty applications in industries such as manufacturing, metal handling, and construction. Nitrile-coated gloves provide excellent chemical resistance and dexterity, recommended for use in automotive, laboratory, and food processing sectors. Industry professionals advise selecting Kevlar gloves for tasks involving sharp objects and high abrasion, while nitrile gloves are preferred for environments requiring chemical handling and precision.

Cost Analysis: Kevlar vs. Nitrile Gloves

Kevlar-coated gloves typically have a higher upfront cost compared to nitrile-coated gloves due to the advanced materials and manufacturing process involved in Kevlar production. Despite the higher initial investment, Kevlar gloves often provide better durability and cut resistance, reducing replacement frequency and potentially lowering long-term costs. Nitrile gloves are more affordable initially but may wear out faster in high-risk environments, leading to increased expenditure over time.

Choosing the Right Glove: Safety Considerations

Kevlar-coated gloves provide superior cut resistance and heat protection, making them ideal for high-risk environments such as metal handling and sharp object manipulation. Nitrile-coated gloves offer excellent chemical resistance and enhanced grip, suitable for tasks involving oils, solvents, and wet conditions. Selecting the right glove depends on prioritizing protection against specific hazards like cuts, heat, or chemicals to ensure optimal hand safety.

Kevlar-coated glove vs Nitrile-coated glove Infographic

materialdif.com

materialdif.com